Case study: Wernsing Feinkost GmbH

How cooperation empowers and increases results

Wernsing Feinkost GmbH

From potato products to pasta, from sandwich spreads to savory snacks, and from salads to desserts: Wernsing Feinkost GmbH makes it all! Their wide range of high-quality food products in many categories makes Wernsing Feinkost GmbH one of the largest food service suppliers in Germany. The company is part of the Wernsing Food Family. In total, over 4,000 people work here. Of these 4,000, more than 1,150 work at the Addrup-Essen site.

During the production of its potato products, Wernsing Feinkost GmbH has been using optical sorting machines to assess the quality of the potatoes for many years. For a long time, it used so-called ‘free-fall’ optical sorting machines, where bad potatoes were ejected. Since the sorting quality of the machines was not high enough, a manual inspection was always carried out by several employees. However, due to rising personnel costs, labor shortages, and increasingly stringent quality requirements, Wernsing decided that they wanted to fully automate the entire sorting process without compromising on quality. That is how they came to us.

100+ different products

1150 employees

7 production facilities with a turnover of 1 billion

The problem

Wernsing came to us and told us that they currently had 12 optical sorters and 10 employees who checked the potatoes after they were categorized as “good product” by the optical sorters. The sorting quality had an accuracy of about 60%. They wanted to get the sorting quality up to > 90% and this without any manual inspection. We gladly accepted this challenge and a development process followed in which we placed one optical sorter in the line next to the current installation for a null measurement.

From day one, our sorter performed much better and we concluded that with a number of small optimizations we could halve the number of sorting machines needed and also ensure that they would not need 10 employees but only one operator.

The solution

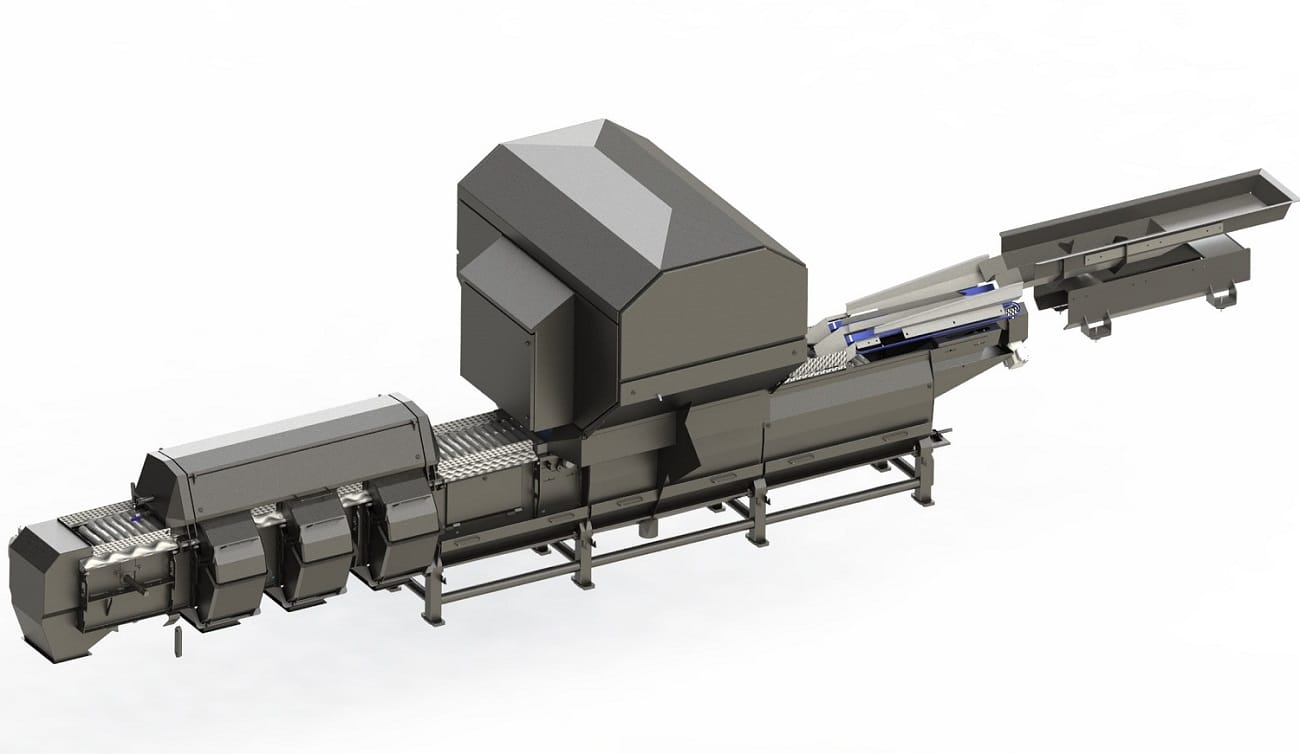

Finally, we installed 6 optical sorting machines including an infeed system at Wernsing Feinkost GmbH. An important factor to achieve the set requirements was not the use of the highly accurate vision software but mainly the combination of this software with our philosophy regarding the ejection of different potatoes. Where other suppliers try to separate the bad (read: waste) product from the good product flow, we separate both categories.

This means that we not only have a separate exit for the bad product but also a separate exit for the good product. This means that one action is required to sort both good and bad products, which results in a minimum chance of product flow mixing (good flow and waste flow).

Delivered machines

6 optical sorters including an infeed system

The result

After a year in production, Wernsing Feinkost GmbH is still working without any manual inspection and the quality (accuracy >95%!) is higher than ever before. The six optical sorters that we have delivered are functioning to full satisfaction and even the amount of maintenance and downtime has decreased in comparison to the original situation. In short, our cooperation has worked out well for both parties and will only be further strengthened in the coming years with other great projects!

The impact

Not only has Wernsing Feinkost GmbH been able to increase product quality by achieving extremely accurate sorting, but they have also been able to deploy 10 employees elsewhere in the company to increase efficiency within other departments. In addition, with the data collected by the optical sorting machines, they can also assess the general potato quality and take action if necessary.

In short, by working together and learning from each other, we managed not only to realize an extremely efficient production line with high product quality but also to develop the most accurate optical sorting machine for (un)peeled potatoes!