Potatoes

How can we help your business?

With decades of experience Marcelissen is your go-to partner for all sorts of potato processing. Whether it’s cutting, peeling or weighing, our machines will excel at the task!

Our machines are equipped for peeling, inspecting, cutting, sorting, transporting and more. With 75 years of experience we customize our machines according to your needs.

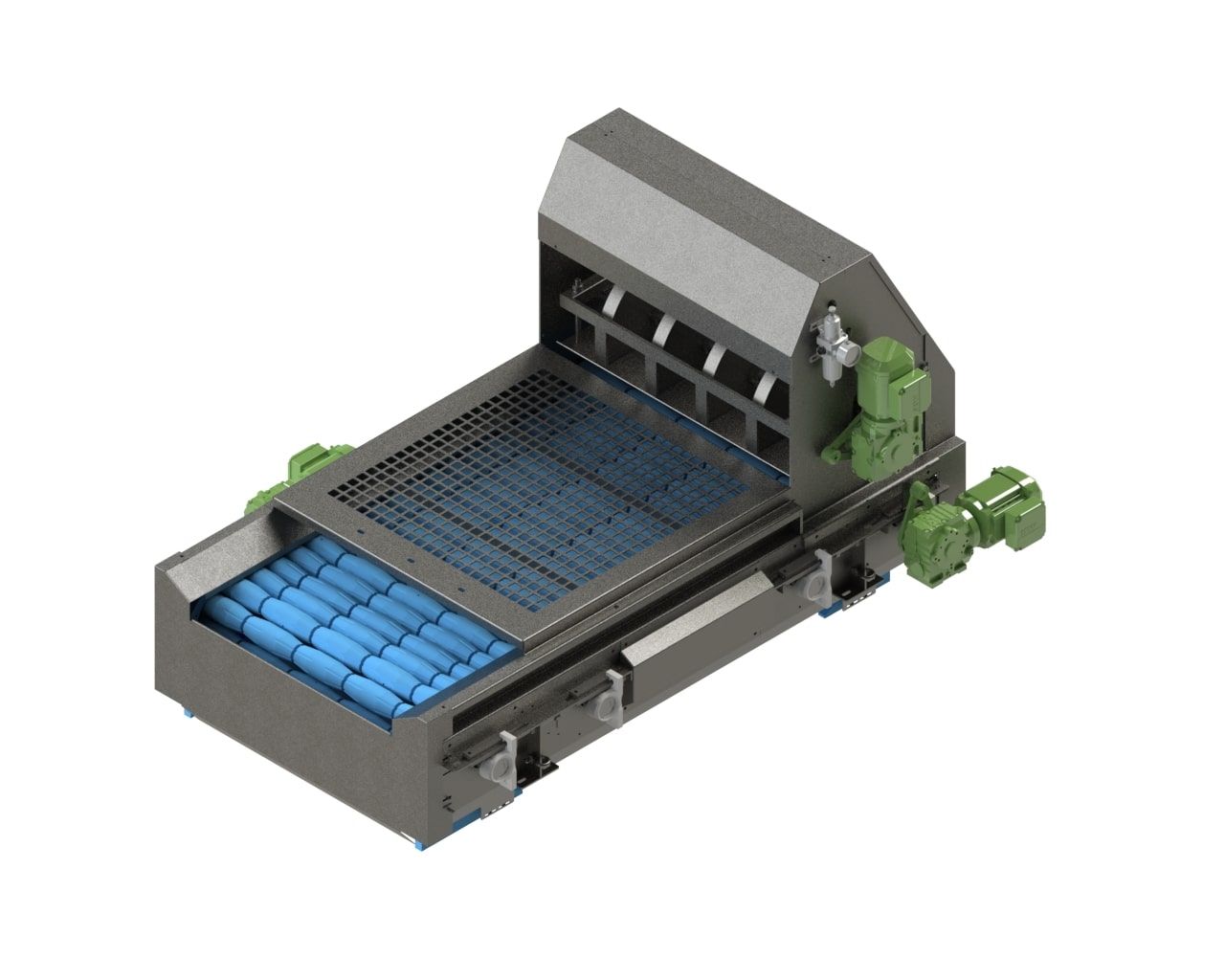

Cleaning, Desoiling & Destoning

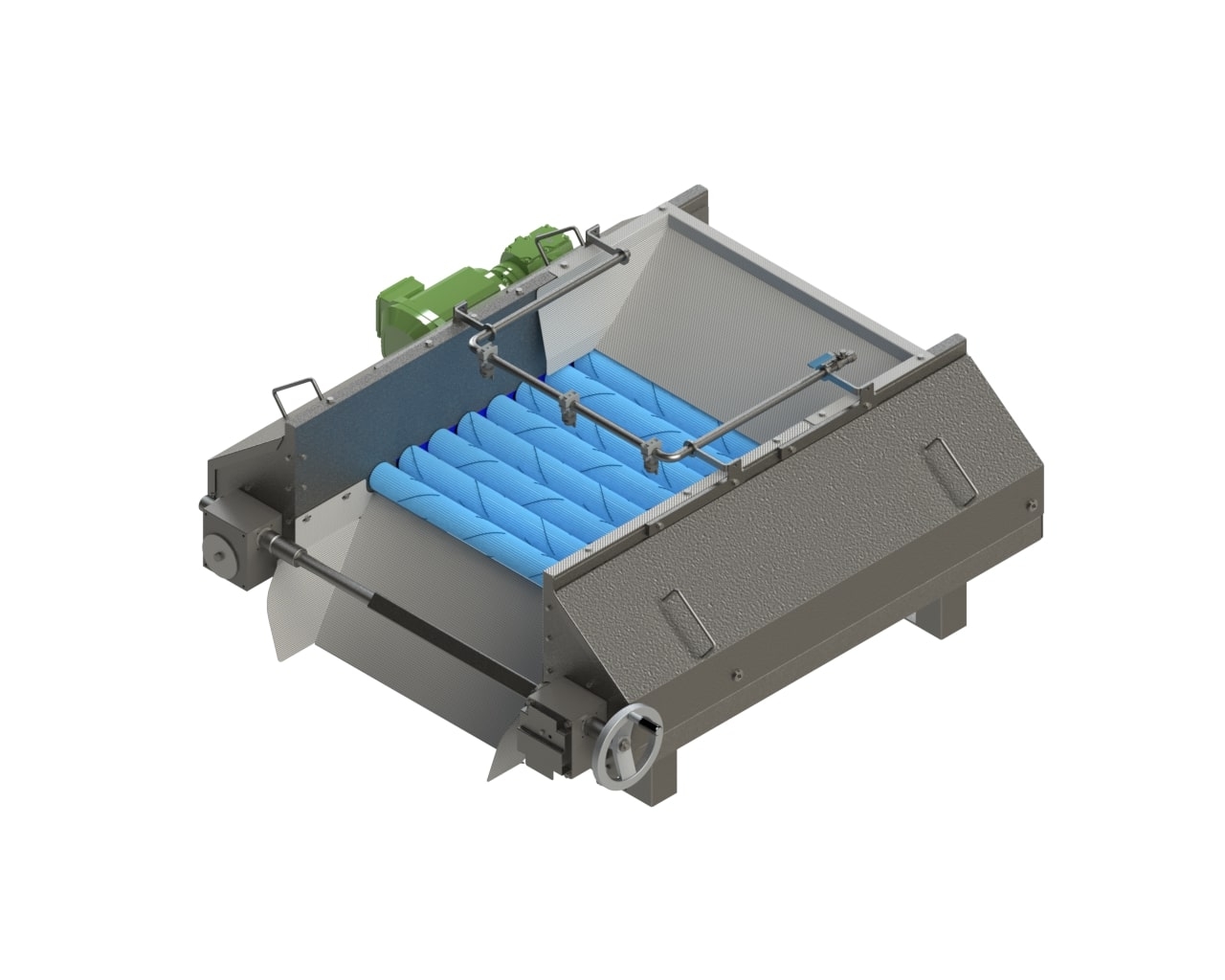

Brushing

Abrasive peeling

Knife peeling

Inspection

Optical sorting

Cutting

Sorting

Weighing

Waste-management

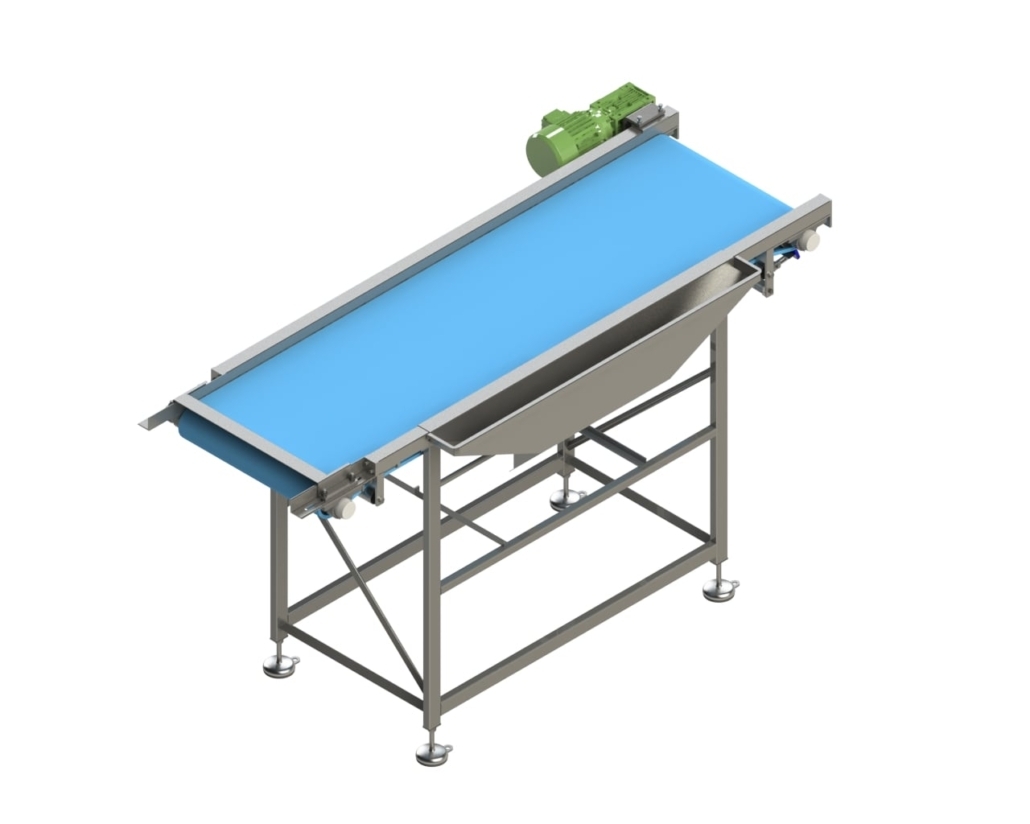

Transport & Infeed

Buffering

Explore our machines

Our machines are equipped for peeling, inspecting, cutting, sorting, transporting and more. With 75 years of experience we customize our machines according to your needs.