Machines

Jump to:

Cleaning, Desoiling & Destoning

Brushing

Abrasive peeling

Knife peeling

Inspection

Optical sorting

Cutting

Sorting

Weighing

Waste-management

Transport & Infeed

Buffering

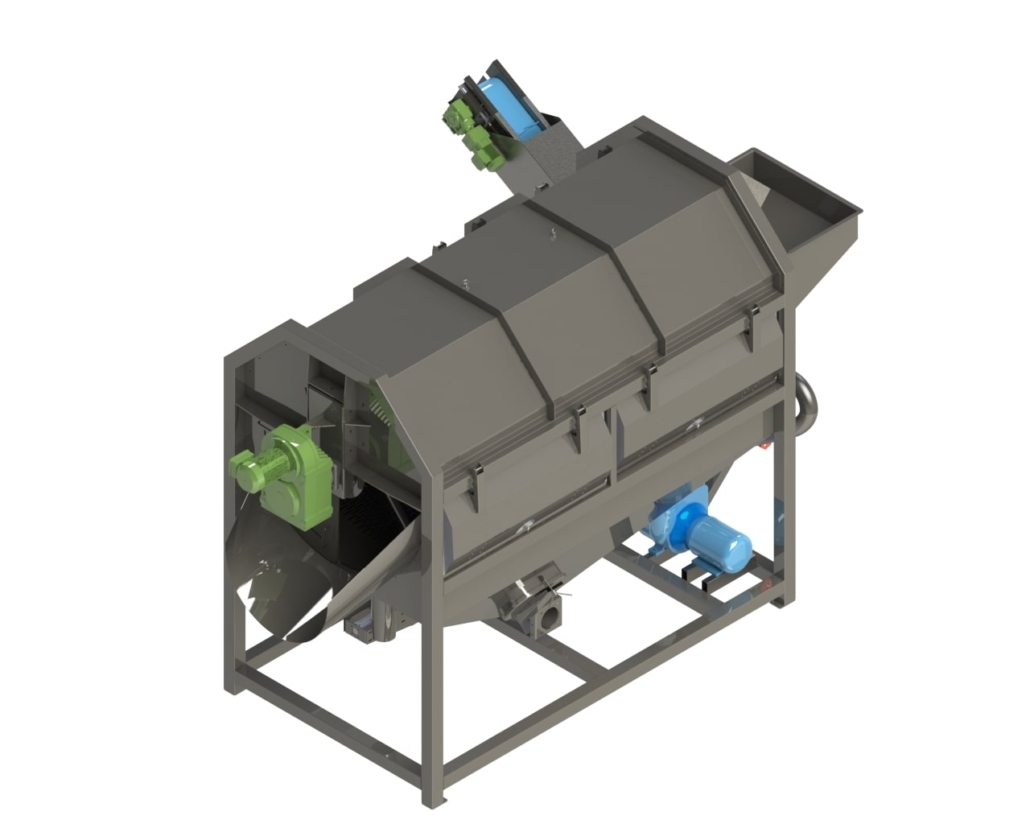

Cleaning, Desoiling & Destoning

Washing Drum – VW

Explore this machineAuger Destoner – VOS

Explore this machineDestoner and Drum Washer – VOW

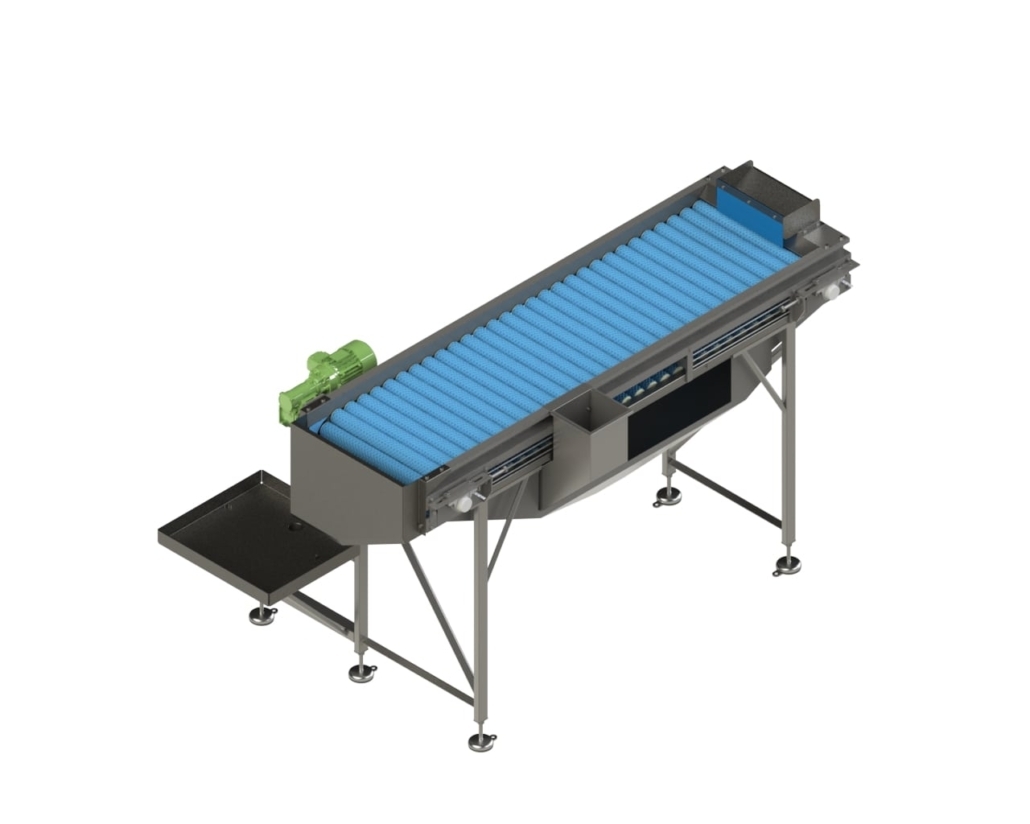

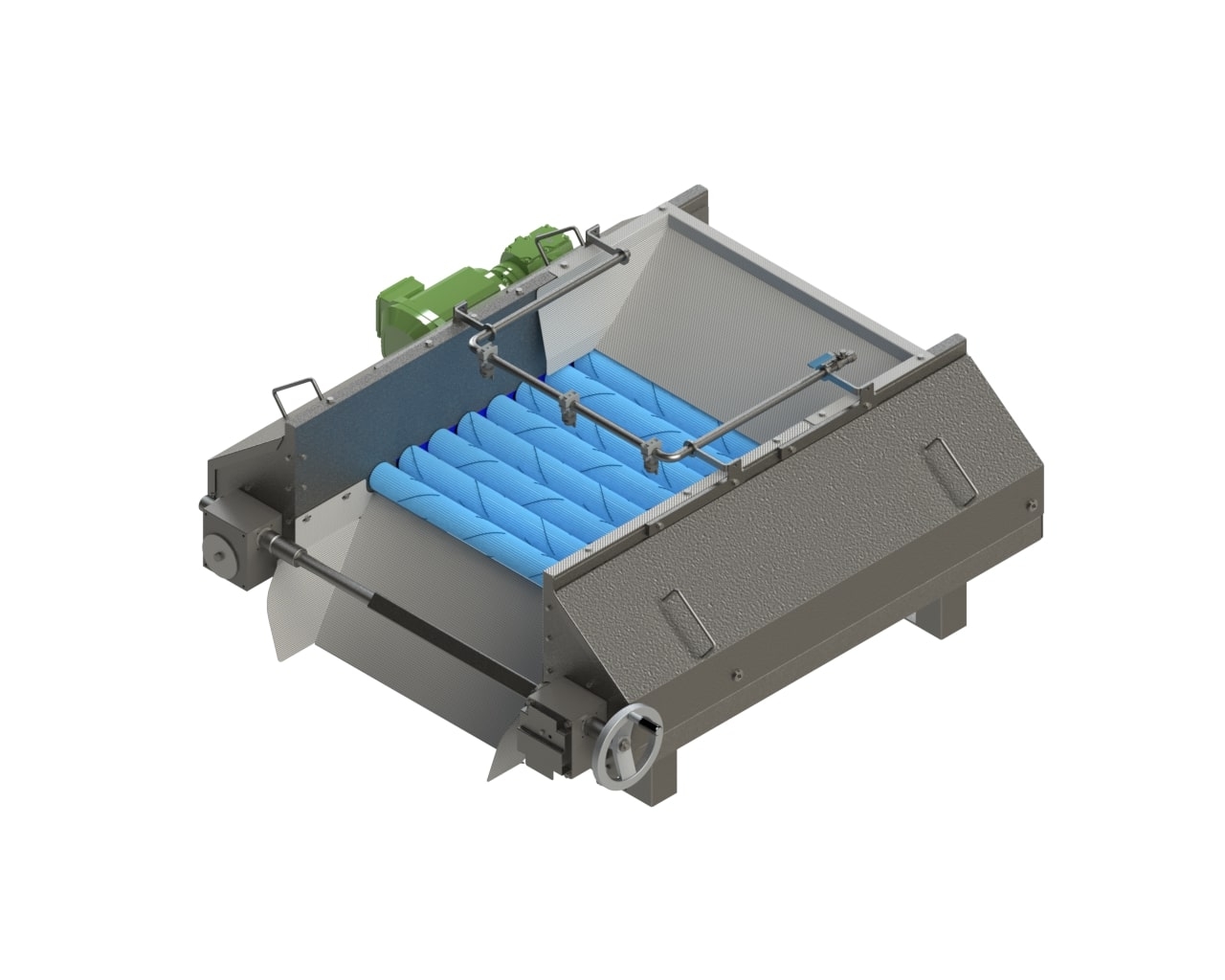

Explore this machineRoller Desoiler – VR

Explore this machineAutomatic Destoner – VAOS

Explore this machineBrushing

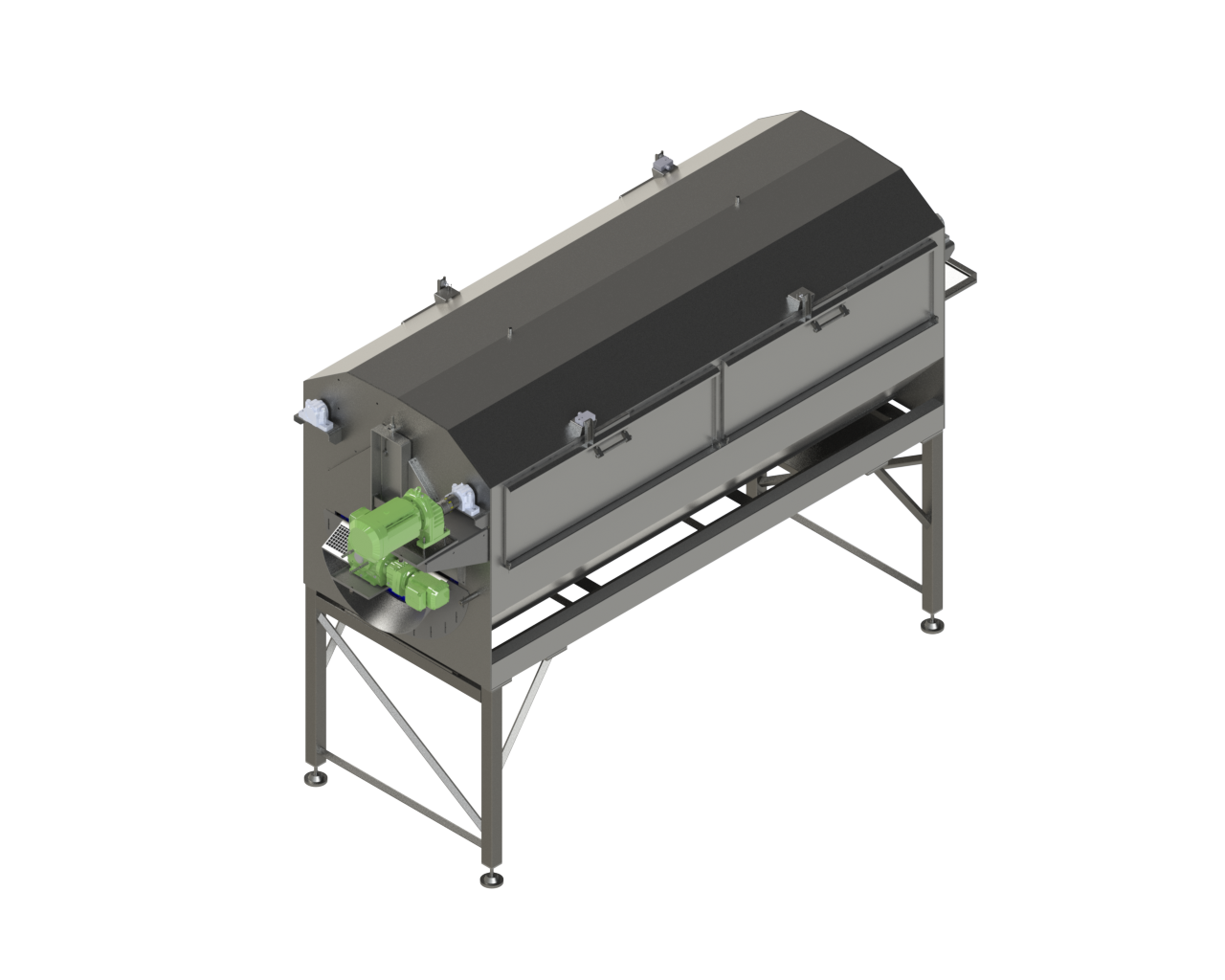

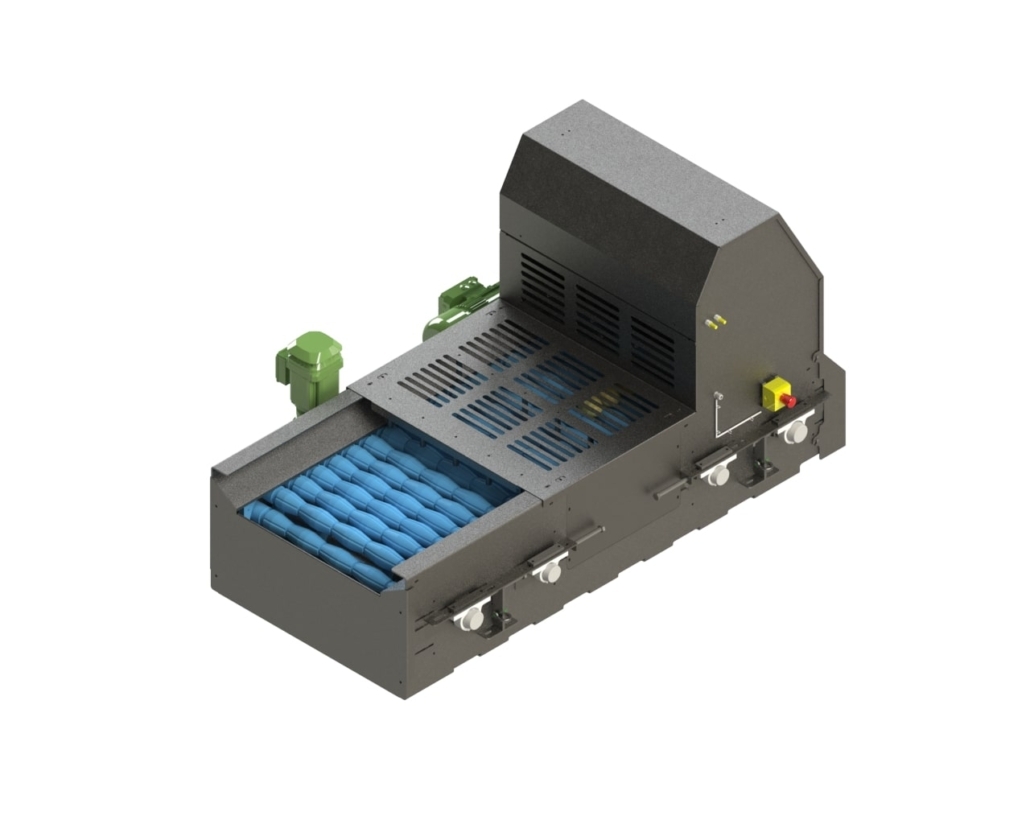

Roller Brushing Machine – NBR

Explore this machineU-Bed Roller Brusher- NBRT

Explore this machineAbrasive peeling

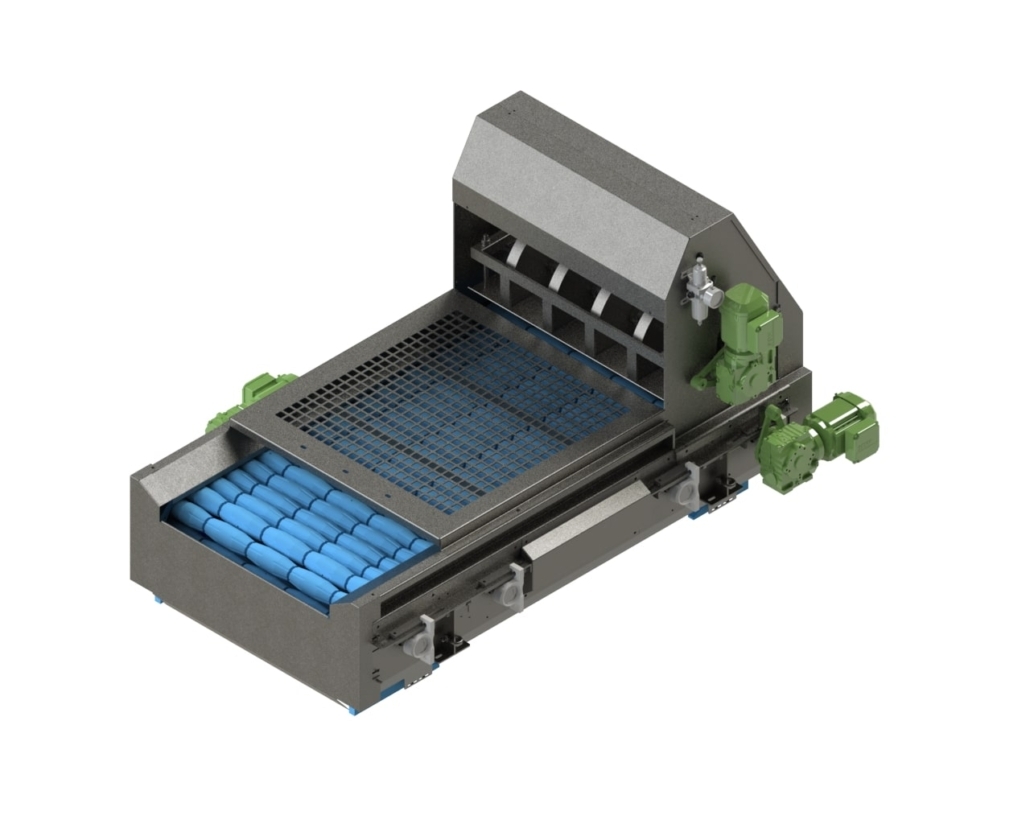

U-Bed Roller Peeler - SKRT

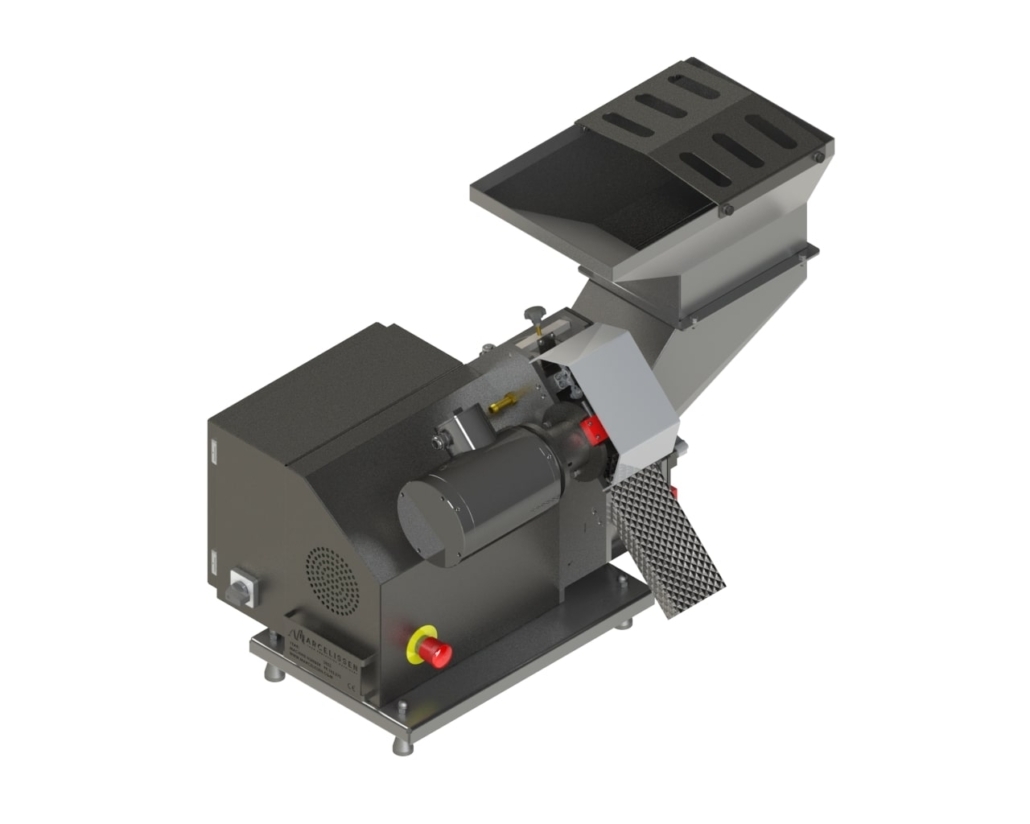

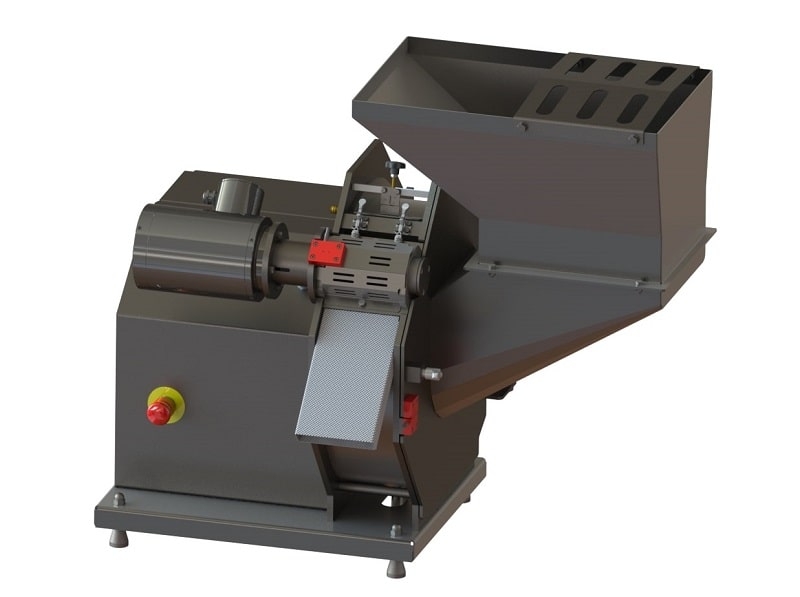

Explore this machineBatch Peeler – SKB Standalone

Explore this machineDrum Roller Peeler – SKR

Explore this machineBatch Peeler – SKB

Explore this machineKnife peeling

Batch Knife Peeler – SMB Standalone

Explore this machineDrum Knife Peeler – SMT

Explore this machineInspection

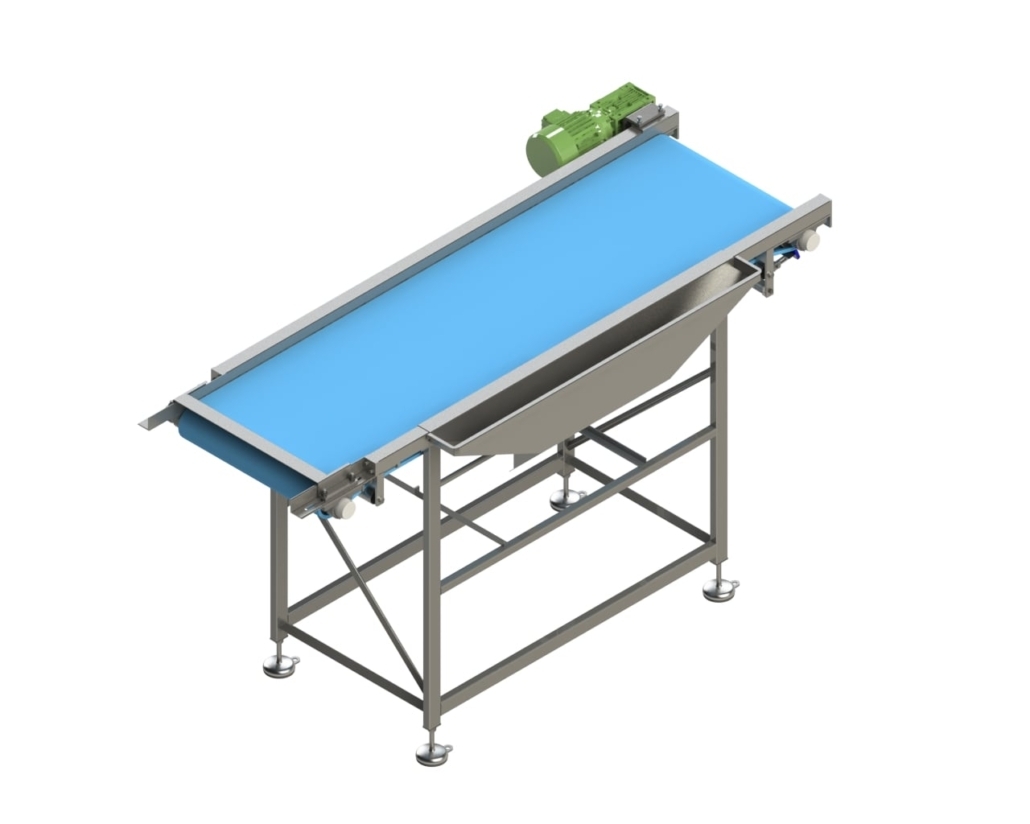

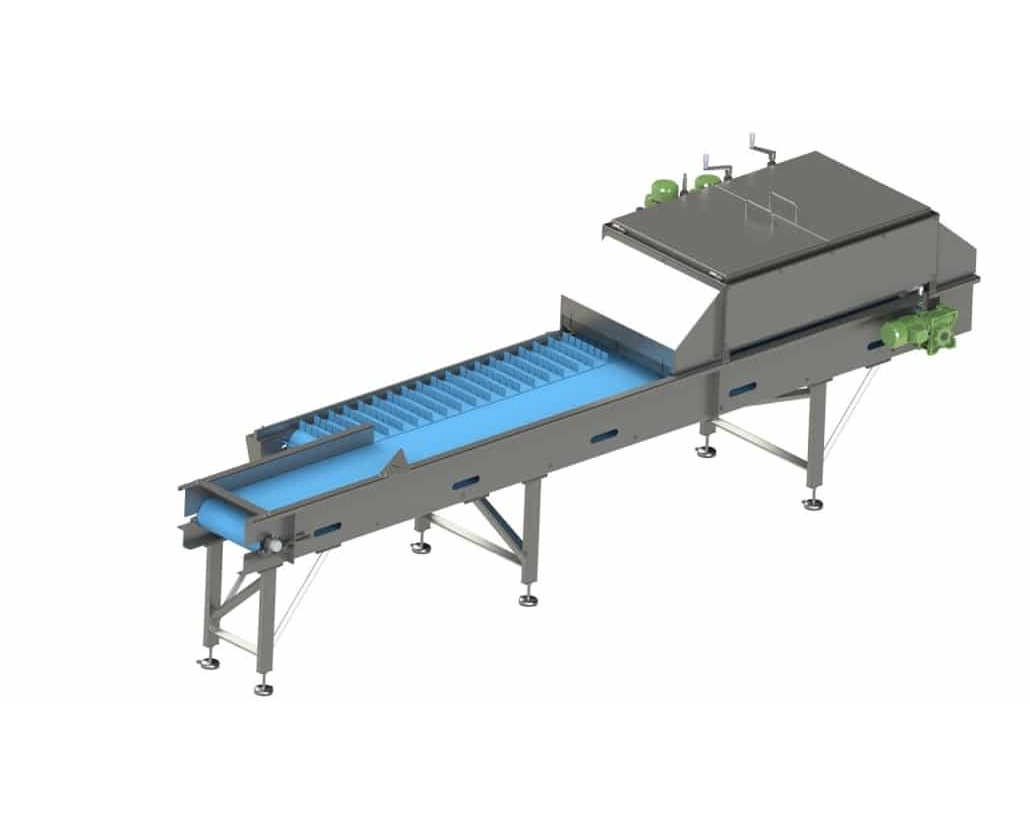

Inspection Belt – IB

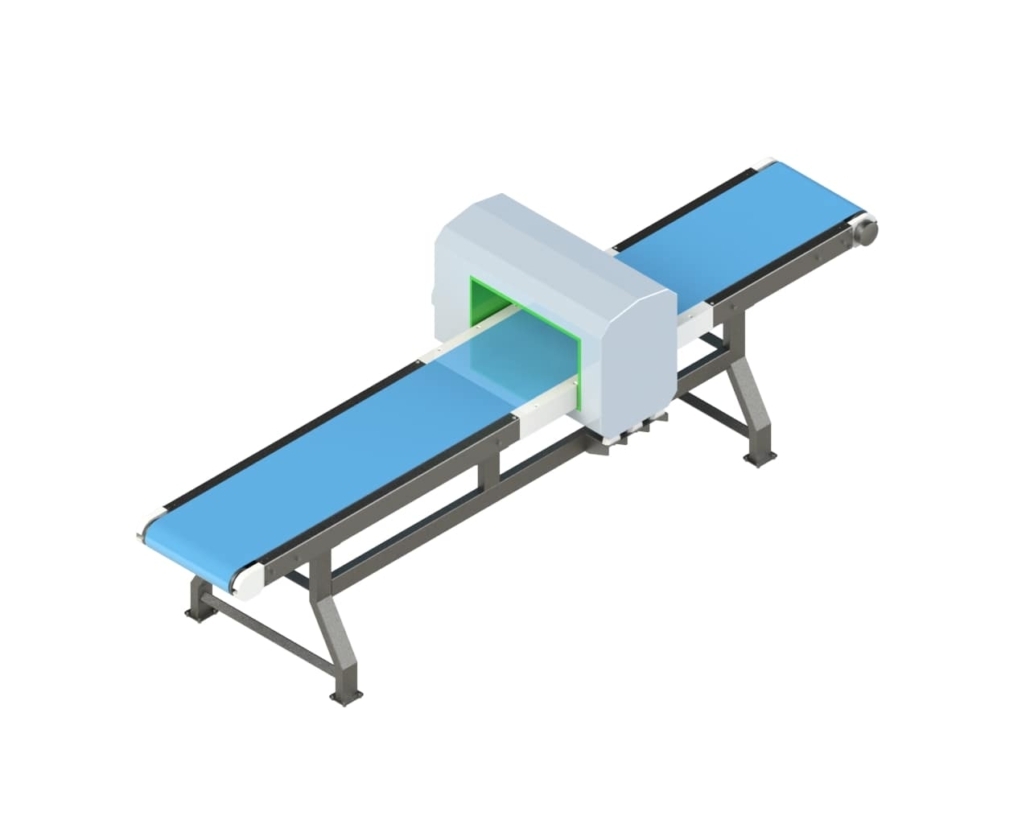

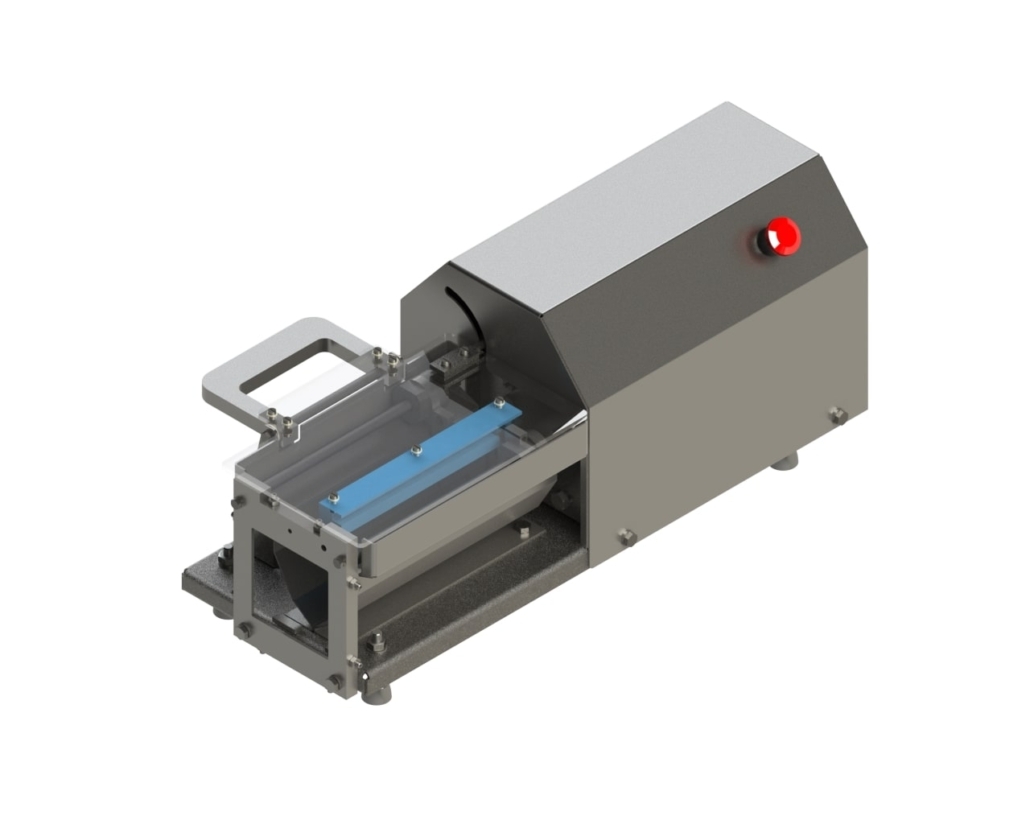

Explore this machineMetal Detection Conveyor – IM

Explore this machineRoller Inspection Belt – IR

Explore this machineOptical sorting

Optical Sorter Mechanical – SOM

Explore this machineOptical Sorter Pneumatic – SOL

Explore this machineCutting

Slitmaster – S

Explore this machineSlitmaster 85

Explore this machineSlitmaster 105

Explore this machineTop/Tail and Plug-Cutting Machines – TTP

Explore this machineStart/Stop Segmenting Machine – D

Explore this machineContinuous Halving Machine – DC

Explore this machineCompact Hydro Cutter – SHC

Explore this machineHydrocutter – SH

Explore this machineSorting

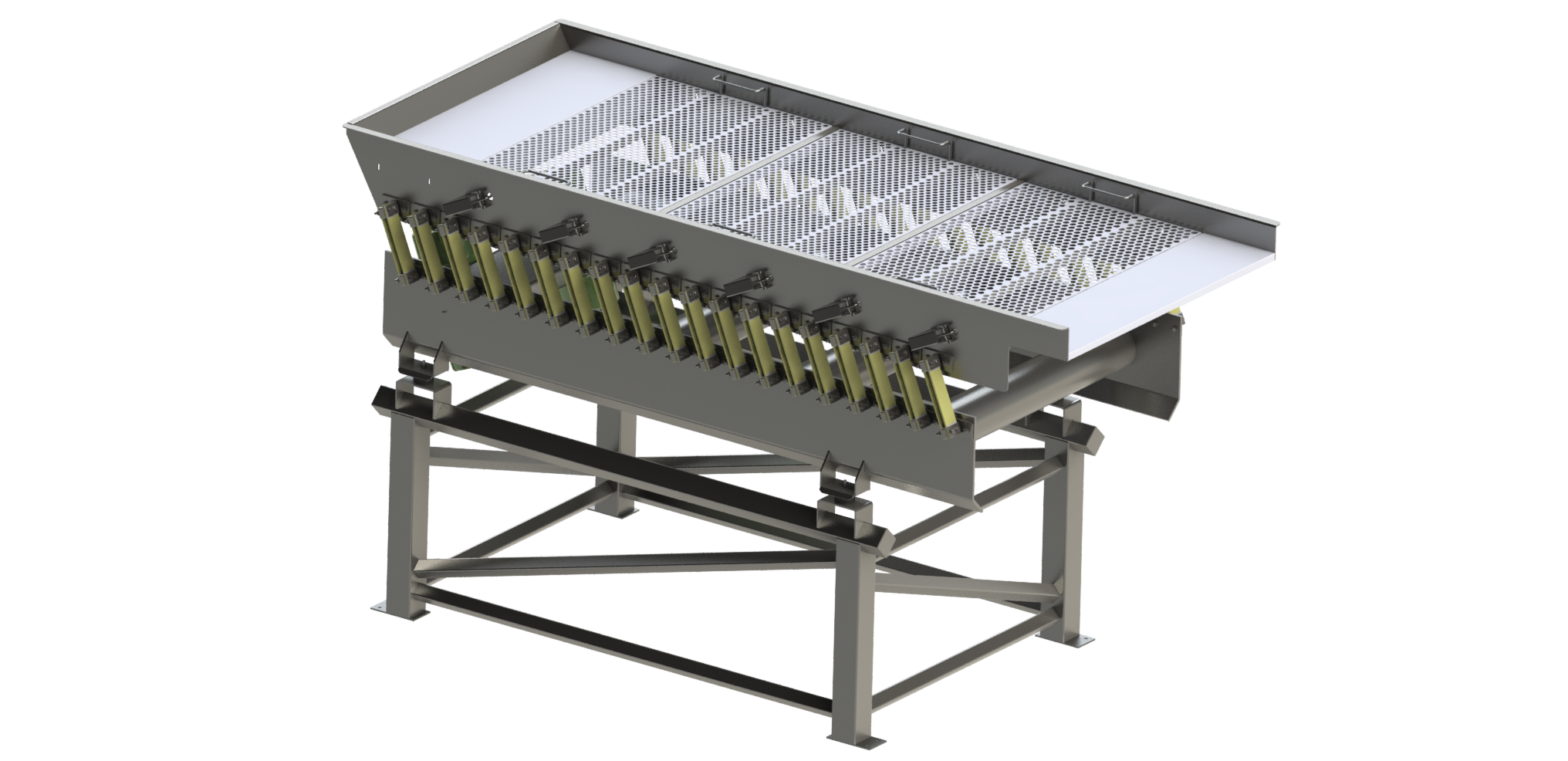

Roller Sorting Machine – SRK

Explore this machineShort Piece Sorter with V-lanes – SV

Explore this machineSliver Remover – SR2-4

Explore this machineSliver Remover – SR2

Explore this machinePotato Diameter Sorter – SRL

Explore this machineSplit Sorter – SR2-S

Explore this machineNubbin Grader - SV

Explore this machineWeighing

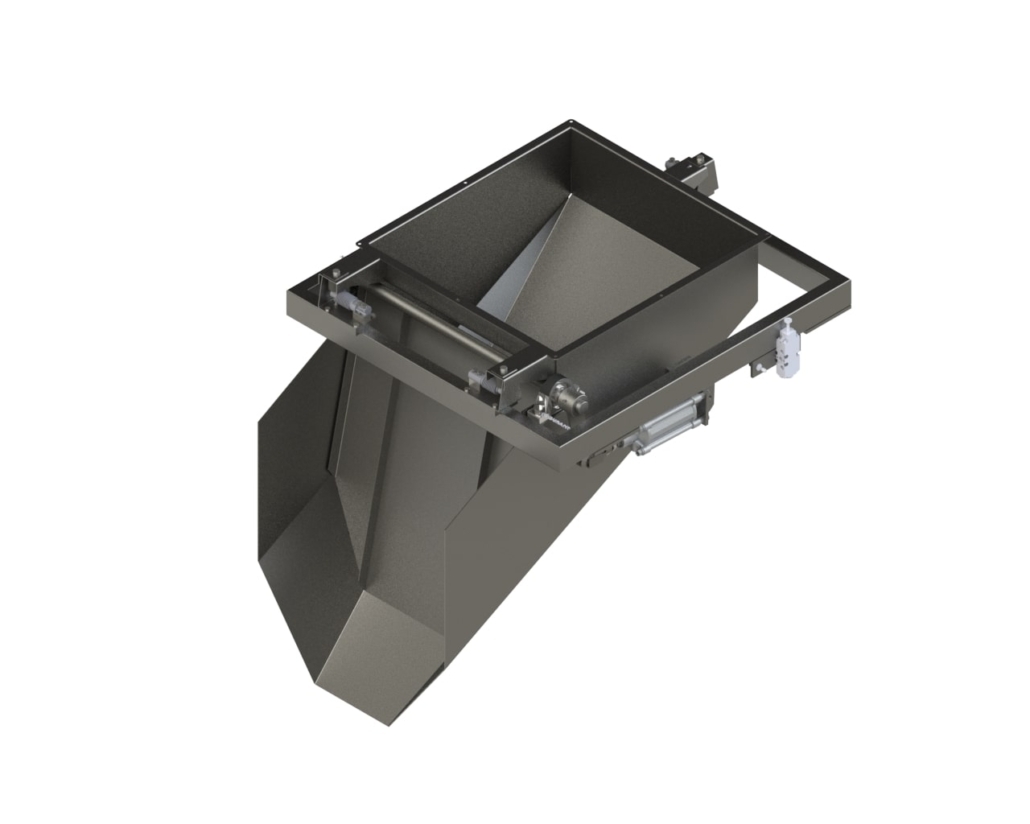

Weigher with Dosing Hopper – AE

Explore this machineWeighing Hopper – A

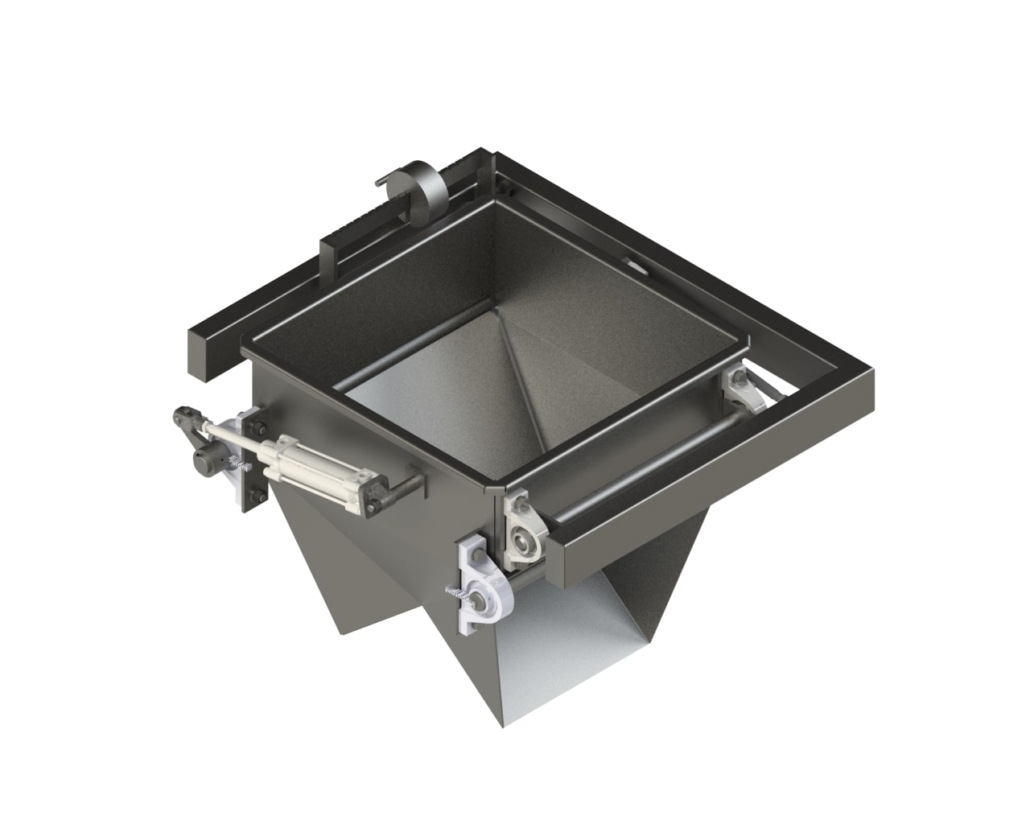

Explore this machineDouble Weighing Hopper – AD

Explore this machineElectronical Weigher with Wet Hopper – AEBNT

Explore this machineElectronical Weigher with Wet Buffer Conveyor Gooseneck – BNTZAE10

Explore this machineWaste-management

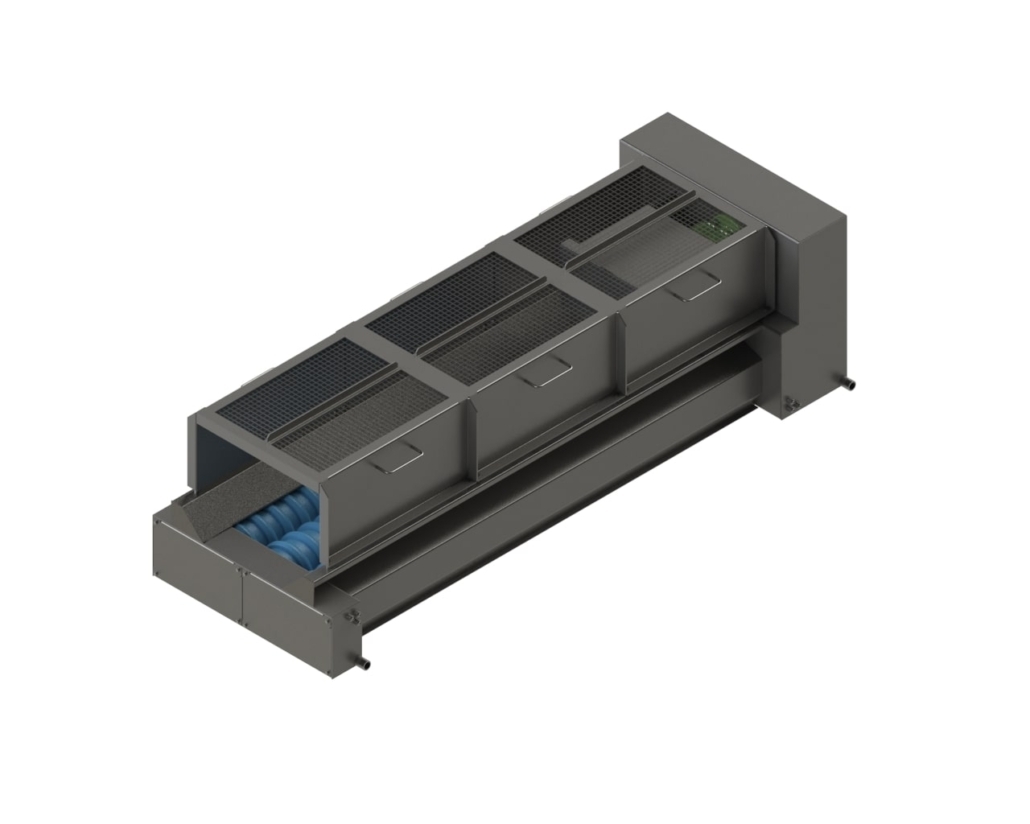

Waste Water Separator – WT

Explore this machineWaste Press Auger – WS

Explore this machineTransport & Infeed

Transport Auger – TS

Explore this machineCooling Auger – NKS

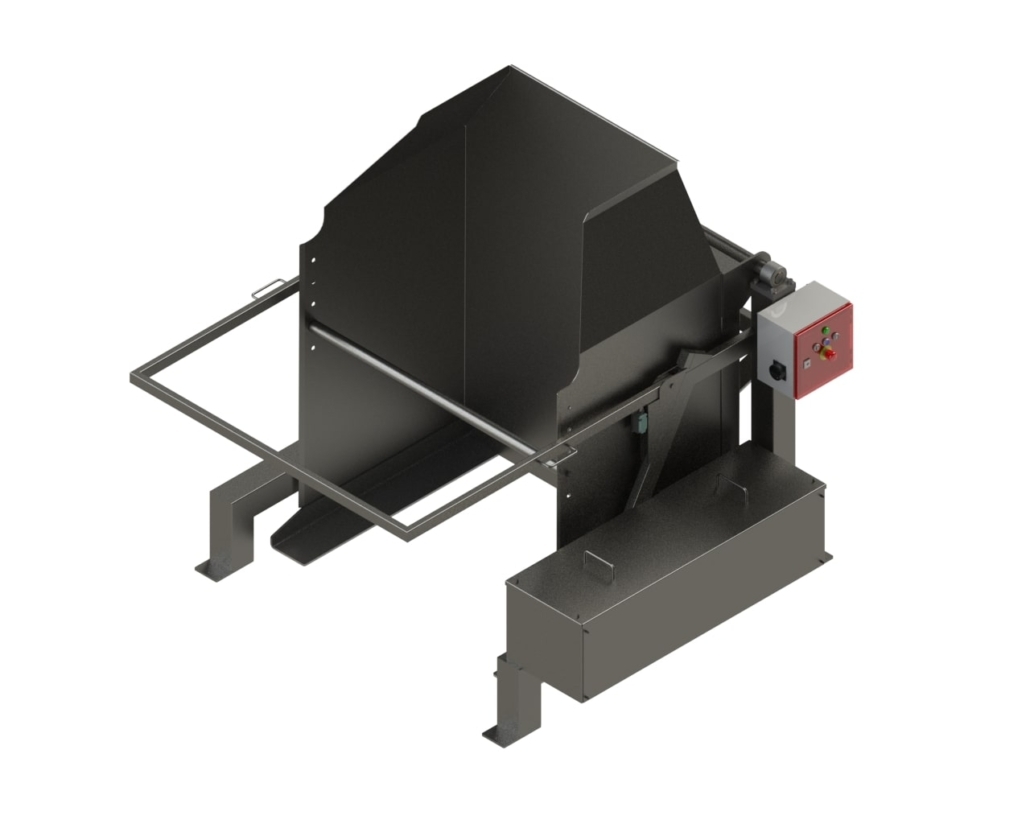

Explore this machineBox Tipper - KH

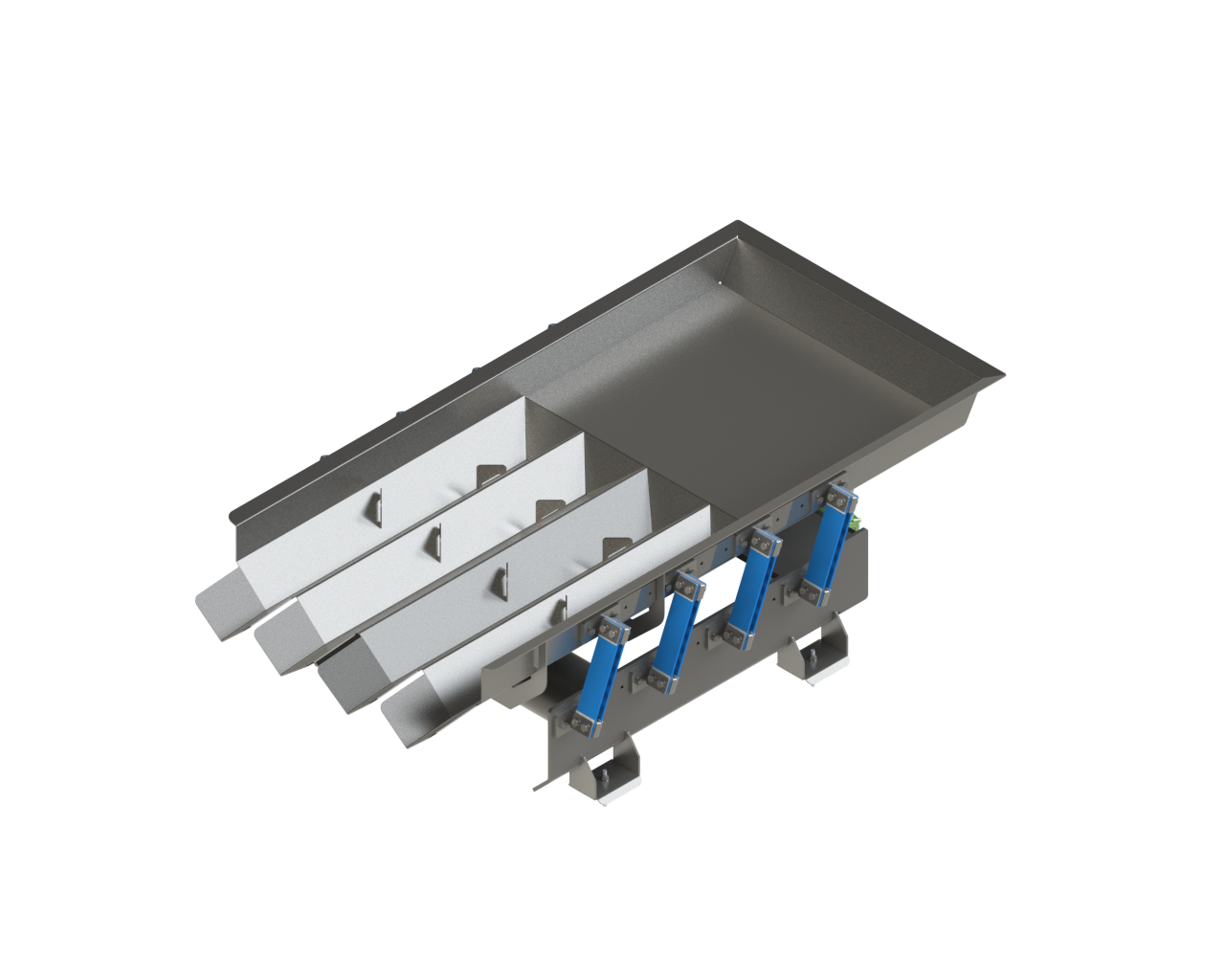

Explore this machineInfeed Shaker - TVV

Explore this machineBuffering

Wet Hopper with Outfeed Gooseneck Conveyor – BNTZ

Explore this machineBunker – B

Explore this machineBunker with Outfeed Conveyor Belt – BT

Explore this machineWet Buffer Conveyor – BNT

Explore this machineWet Buffer Screw Conveyor – BNTS

Explore this machineWe offer complete lines

Whether you are peeling, inspecting, cutting, sorting, washing or transporting potatoes, fruits, root vegetables or nuts, at Marcelissen we have the solution. With innovative food processing machines in our portfolio we never have to say no to any challenge.