Industrial Fries Cutter

Who doesn’t love French fries? Your guests really appreciate it when you serve homemade, fresh fries. After all, fresh fries taste best, don’t they?

To offer your guests fresh fries, a fast and efficient professional fry cutter is necessary. After all, time is of the essence in the catering industry. Marcelissen has three high-quality French fries cutters for professional use:

- The Slitmaster 85

- The Slitmaster 105

- The Slitmaster SLS200

The professional French fry cutters are ideal for restaurants, French fry stores and snack bars. We would be happy to tell you more about the solutions.

Professional electric French fry cutter for catering and commercial kitchens

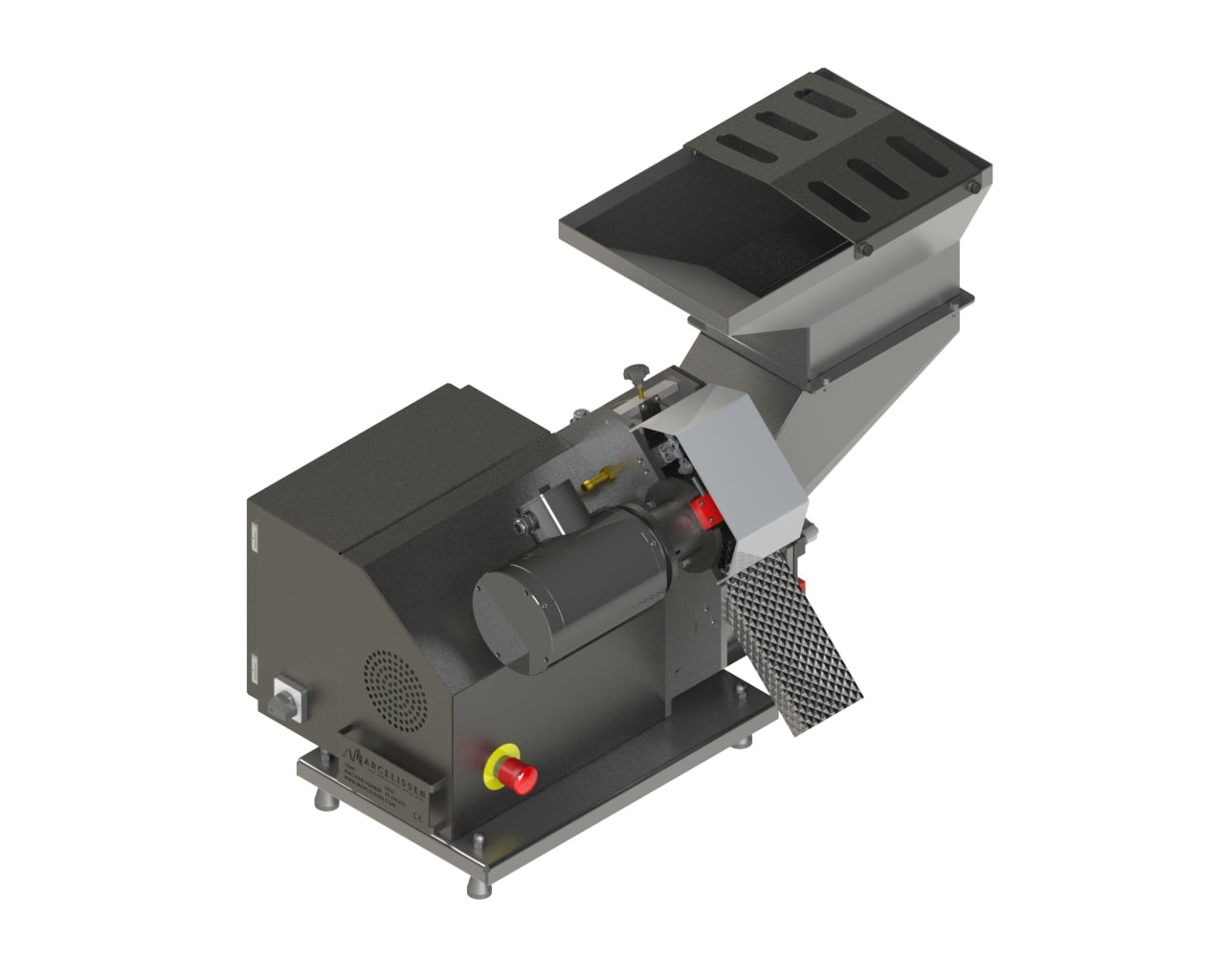

The Slitmaster 85 is the ideal solution for cutting large quantities of potatoes into fresh fries at speed. This catering fries cutter is made of high quality material (stainless steel). Thanks to its high capacity of 1,500kg/hour, you can cut much more fresh fries within a short time than would be possible with a regular hand cutter.

Image 1: De Slitmaster 85

This electric French fry cutter can cut both peeled and unpeeled potatoes lengthwise, so you can always serve the longest possible fries. Also, this minimizes your cutting waste.

Also, the thickness of the fries can be set as desired (7 to 14 mm). This makes several fries variations possible, such as slices, crinkle fries, Flemish or Steakhouse fries. For an authentic look, the fries can be cut in a slightly curved way. Thanks to its compact size, the Slitmaster 85 fits into any catering large kitchen.

In addition, thanks to its low-maintenance design, this French fry cutter is also easy to clean. The Slitmaster 85 also possesses a “Quick-release system” making it easy to change the stainless steel blades. All in all, the ideal professional French fry slicer!

Watch a demonstration video of the Slitmaster 85 below:

Mechanisme van de Slitmaster 85

The Slitmaster 85 works as follows. Potatoes enter a rotor when dispensed through an infeed chute. This rotor then takes the potatoes and pushes them through the stainless steel knife section, resulting in long fresh fries. It is important that the bearing bushings are lubricated by water to wash away starch. Please note that a knife roller/knife block set is not included as standard and must be ordered separately.

View the technical specifications of the Slitmaster 85 here:

| Type | Slitmaster 85 |

| Capacity | Max. 1500 kg/hrr* |

| Product infeed | Continuous |

| Dimensions | 900 x 590 x 650 mm |

| Product diameter | 35 – 80 mm |

| Product lenght | 35 – 200 mm |

| Cutting sizes sticks | 7 – 17 mm |

| Cutting sizes schijven | 3 – 17 mm |

| Installed power & electrical connections | 0,92 kW, 230 V, 50 Hz, IP56 |

| Materials | AISI 304 |

Professional French fry cutting machine

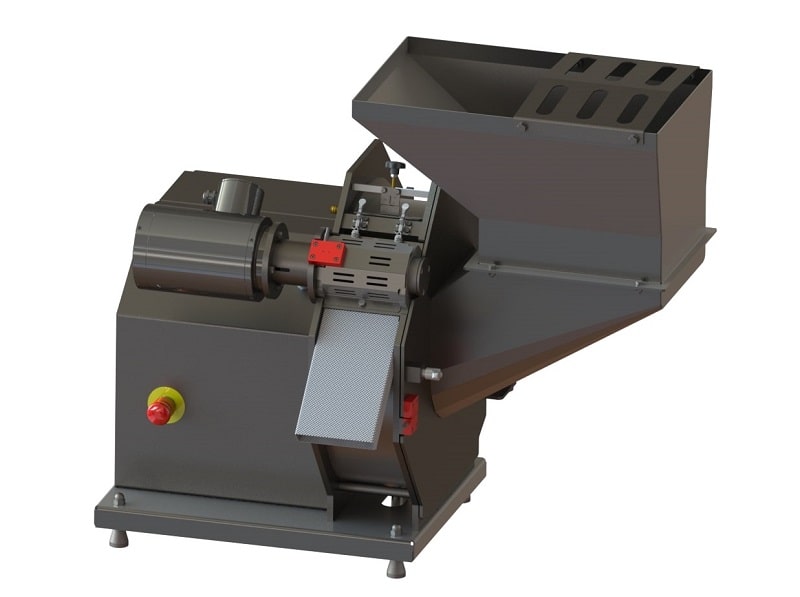

Image 2: Slitmaster 105

The Slitmaster 105 is the ultimate solution for companies looking to optimize their french fry cutting process and maximize efficiency. The machine is capable of slicing potatoes up to 105 mm in diameter. This makes the machine perfect for processing large potatoes.

The French fry cutter is designed with innovative features that significantly improve the cutting process. Like the 85, the Slitmaster 105 always cuts the longest possible fries from each potato.

Another advantage of the Slitmaster 105 is the simple “quick-release” system that allows the knife roller set to be changed in less than a minute. This saves companies valuable time and minimizes downtime. This is especially useful for businesses that need to change cutting sizes frequently to meet customer demand.

This professional French fry cutting machine is made of high-quality materials and components. This makes the machine an excellent investment for companies looking to improve their cutting process and maximize efficiency. The Slitmaster 105 is the perfect solution for companies looking for a high-quality slicer for the production of large fries potatoes.

Watch a demonstration video of the Slitmaster 105 below.

Competitively priced cutter

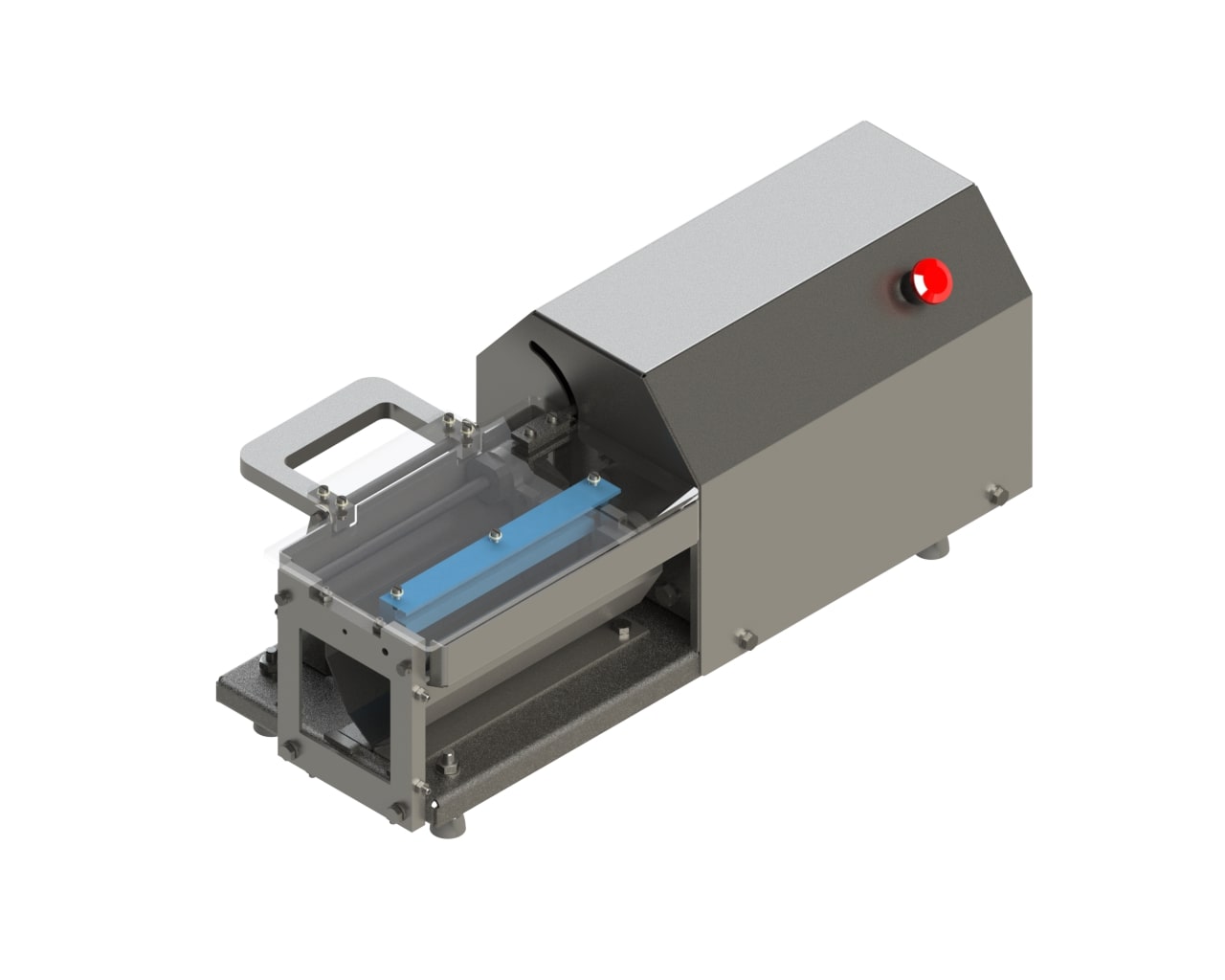

Image 3: Slitmaster SLS200

An electric French fry cutter is ideal for the catering industry, although we understand that price-wise this is not interesting for everyone. Therefore, we also have a so-called pneumatic solution that is similar to the Slitmaster 85 in many respects, but a lot lower in price.

This is the Slitmaster SLS200, a professional potato cutter driven by means of a compressor. So this cutter uses compressed air instead of electricity. Please note that the compressor is not included as standard.

Also with this catering fries cutter you can cut a large amount of fresh fries in no time. Potatoes, both peeled and unpeeled, are cut lengthwise into French fries or wedges. This ensures the finest fries and minimizes cutting waste.

Operation of the pneumatic French fry cutter

The Slitmaster SLS200 is very easy and fast to use. Potatoes are fed through the top. After the safety door is closed, the pneumatic arm pushes the potatoes through the stainless steel knife section.

Watch the video below for a demonstration of the Slitmaster SLS200:

Check out the technical specifications of the Slitmaster SLS200 below:

| SLS200 | |

|---|---|

| Capacity | Up to 250 Kg/uur* |

| Product Infeed | Manual |

| Dimensions | 710 x 240 x 300 Mm. |

| Potato size | max 105 mm diameter max 200mm length |

| Stick sizes Wedge sizes | 7 – 25 mm afh. vd aardappel |

| Air consumption | Per stroke 14 Liter Max 280L/min |

| Materials | Stainless steel, glass blasted. Drive components and other parts of normal material |

* Depending on product diameter, feed rate and product quality

Our Customers

At Marcelissen, we have already been able to set up various machines and production lines for various customers, and we are proud of that. These include large parties such as ‘Farm Frites’, ‘Celavita’, ‘Aviko’ and ‘McCain’.

We are happy to help you!

There are many options for a professional fry cutter catering industry. Marcelissen’s slicers are ideal for this purpose, with the Slitmaster 85 being the best in terms of quality. For some, the purchase price of this fries cutter is too high, so the Slitmaster SLS200 (a pneumatic variant) may be more suitable.

For questions or more information about our catering French fry cutters, you can always contact us. Please fill out the contact form to do so, we will then contact you as soon as possible.

Interested? We’ll get in touch with you!