Roller Inspection Belt – IR

Quality and Innovation

by Marcelissen

Suitable for

Potatoes, root vegetables, fruit, pistachios

Interested?

Get in touch with us

Quality and Innovation

by Marcelissen

Suitable for

Potatoes, root vegetables, fruit, pistachios

Interested?

Get in touch with us

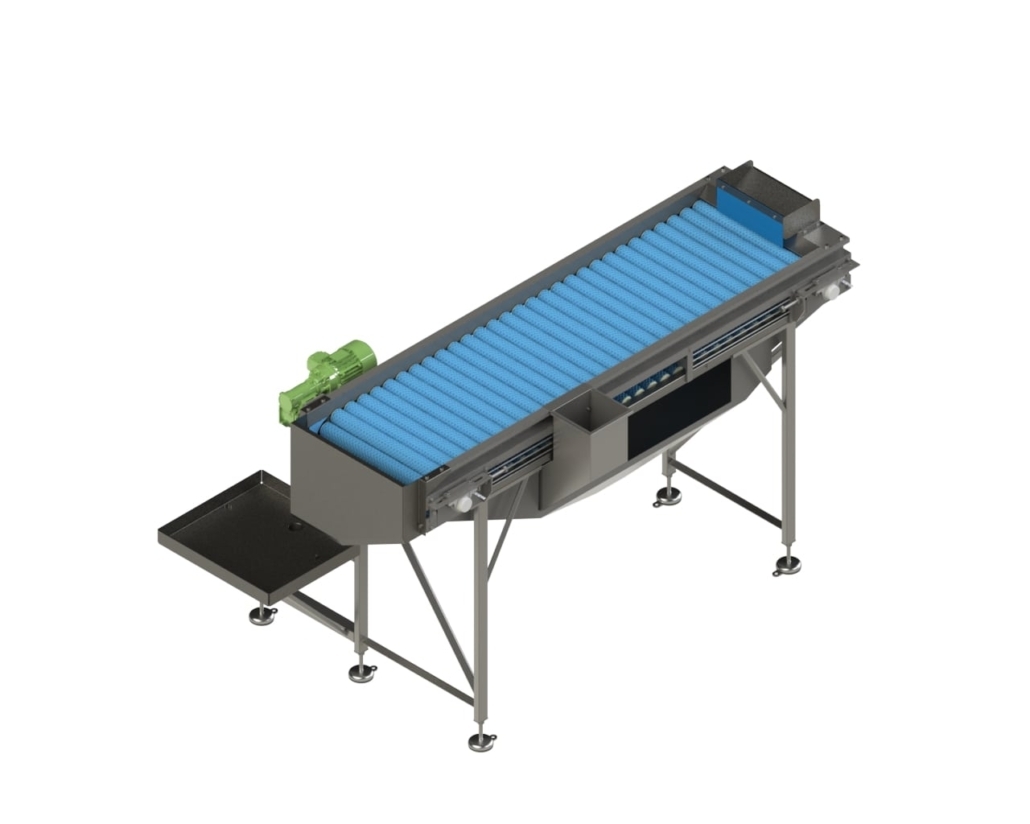

Easy and comprehensive inspection

The Roller Inspection Belt - IR, also known as an inspection conveyor or roller sorting table, is designed for efficient inspection and sorting of root vegetables. Utilizing rotating rollers to turn and move the product forward, this machine ensures a thorough inspection process. Equipped with blue, food-approved rollers (RAL 5017), it provides a hygienic and safe environment for food handling.

The rollers are transported by two parallel-running chains over a support structure, creating a smooth forward motion. The special profile on the rollers ensures 360-degree product rotation, allowing for easy and comprehensive inspection of each item, making it an essential addition to any production line.

This roller conveyor is a valuable addition to any production line, providing reliability, efficiency, and high hygiene standards for product inspection.

Advantages of our Roller Inspection Belt

Efficient inspection for spotting defects.

Versatile for various types of products.

Hygienic design for safe food handling.

What our clients say

Contact us

Curious about the options, the performance of the machine, a price quote? Contact us to discuss your needs!

Contact information headquarters