Potato Line

How can we improve your process?

Designing and manufacturing a potato processing line requires meticulous attention. The potato, a globally consumed product, has numerous applications. Proper handling of the production process is crucial, as product quality deteriorates if mishandled. Thus, a customized solution and a partner who listens and understands your needs are essential. Co-engineering is a key concept for us, and we apply it to all our potato lines.

Batch Peeler Machine - SKB

The Batch Peeler Machine SKB500 is a batch machine with an abrasive peeling disc of approximately 500 mm diameter. A well-dosed filling is essential for optimal peeling results. The machine operates electro-pneumatically via a PLC-controlled cabinet, with the peeling time and unloading time adjustable.

Technical details

Evenly peeled products.

Up to 500 kg/hr.

Of peel waste and water.

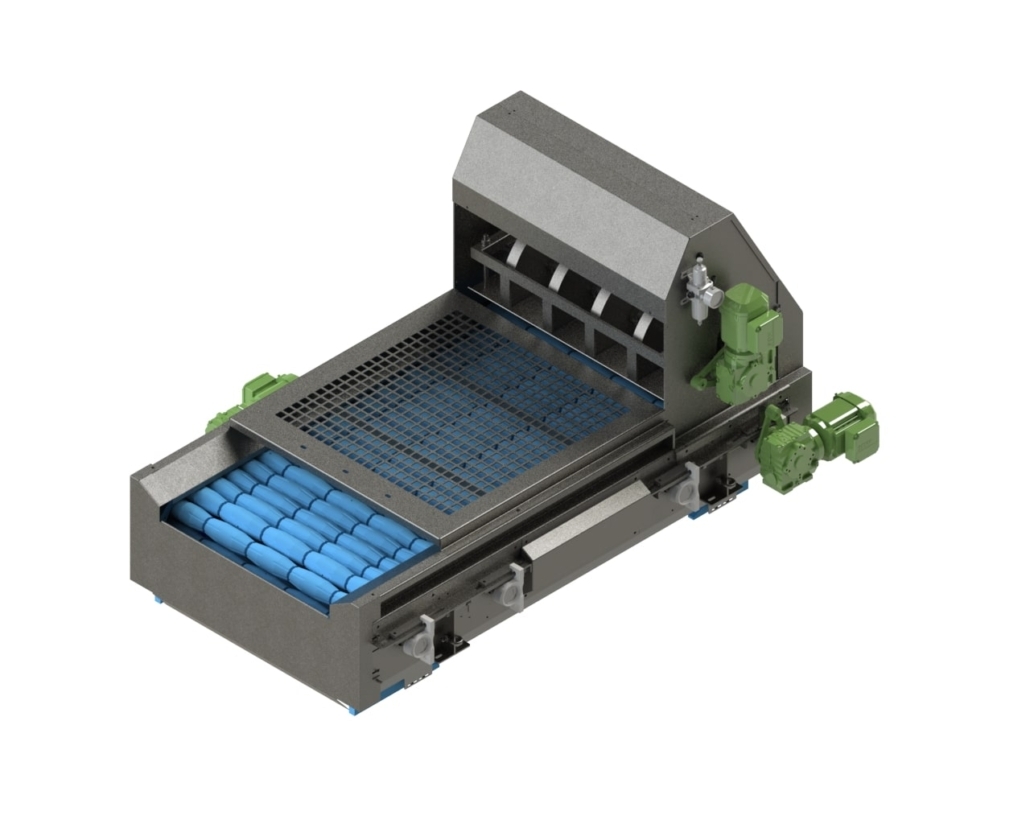

Bunker with Outfeed Conveyor - BT

This machine is designed for product intake at the start of a processing line, potentially following a box tipper. It features an inclined conveyor belt with a chevron profile for efficient product feeding. Key features include an infeed hopper with a discharge conveyor, adjustable belt speed to ensure optimal outfeed, and availability in different widths to accommodate various applications. The machine ensures efficient and versatile product handling at the beginning of the processing line.

Technical details

Efficient production feed.

Various applications possible.

In different belt widths.

Drum Roller Peeler - SKR

The Drum Roller Peeler – SKR is engineered with abrasive linen rollers that form a rotating drum, ensuring efficient and thorough peeling of your root vegetables. The machine features a transport auger inside the drum to regulate transit time. The speeds of the rollers, drum, and auger are adjustable via frequency converters, allowing for precise control over the peeling process.

Technical details

High-quality output.

Up to 7,500 kg/hr.

Waste Management.

Roller Brushing Machine - NBR(T)

The Roller Brush Machine – NBR features independently rotating brush rollers and drum, allowing for versatile cleaning applications. Its adjustable speed settings ensure optimal cleaning performance tailored to your needs. Designed for efficiency, this machine delivers uniform product cleaning with ease of use, making it ideal for large-scale operations.

Technical details

Drum and roller rotation.

Adjustable speed settings.

Uniform product cleaning.

Drum Knife Peeler - SMT

The Drum Knife Peeler – SMT from Marcelissen sets the standard for knife peeling and re-peeling potatoes and other root vegetables like carrots, trusted by companies worldwide. This machine features stainless steel knife bars that form a stable rotating drum, ensuring even and complete peeling at low speeds.

Technical details

Optimal peeling.

Up to 10,000kg/hr.

Materials.

Optical Sorter Pneumatic - SOL

The Optical Sorter Pneumatic - SOL is an expertly engineered machine for optically grading both peeled and unpeeled potatoes. Using an advanced 360° camera system, this machine assesses defects, color, size, shape, and waste. After this assessment, the potatoes are automatically segregated using pneumatic valves, ensuring only the best potatoes make it through your production line. It is equipped with a dosing unit, roller belt, camera unit, and ejection zone, each designed for optimal performance.

Technical details

Sorting by defects, color, size, shape, and waste.

Multiple exit configurations.

Hygienic design.

Continuous Halving Machine - DC

The Halving Machines we offer have a unique input belt which measures out potatoes carefully, resulting in single layers of product on the belt. This ensures every potato is cut in half in the most efficient way possible. Discover the unparalleled performance of our Continuous Halving Machine DC, specifically designed for efficiently and accurately halving potatoes. This innovative machine offers a seamless solution for the food industry, with a focus on quality and speed.

Technical details

Precision with self-aligning roller bed.

Double inspection when processing.

Rotary blades ensure accurate cuts.

The process

The end product dictates the design of a potato processing line. At Marcelissen, we offer a comprehensive range of equipment and configure it to achieve your needs and product specifications. This ensures the optimal potato processing line for your specific situation. Despite our flexibility in determining and manufacturing the ideal solution, we employ a standardized approach to identify requirements:

Our expertise

Co-creation

As a family-owned company we value cooperation and the mutual trust that comes with it. We work with you to achieve mutual goals.

Custom-made solutions

Our experience translates into commitment, trust and a deep knowledge of the technology, the market and the needs our customers face.

Highest quality

The quality of your product depends on the quality of our machines. All of Marcelissen’s machines are made with the best quality materials and engineering.

Innovative technologies

Innovation is key. The Sliver Remover is a Marcelissen innovation, for instance. By implementing the latest technology we stay ahead and deliver high quality and innovative machines to the market.

Reducing waste

All our machines are made with efficiency in mind. Reduce both food waste and water consumption and increase efficiency at the same time.

What our clients say

Interested in how we can help you?

Whether you are cutting, peeling, sorting, washing or transporting potatoes, fruits, root vegetables or nuts, at Marcelissen we have the solution. With innovative food processing machines in our portfolio we never have to say no to any challenge.