Top/Tail and Plug-Cutting Machines – TTP

Quality and Innovation

by Marcelissen

Suitable for

Root vegetables

Interested?

Get in touch with us

Quality and Innovation

by Marcelissen

Suitable for

Root vegetables

Interested?

Get in touch with us

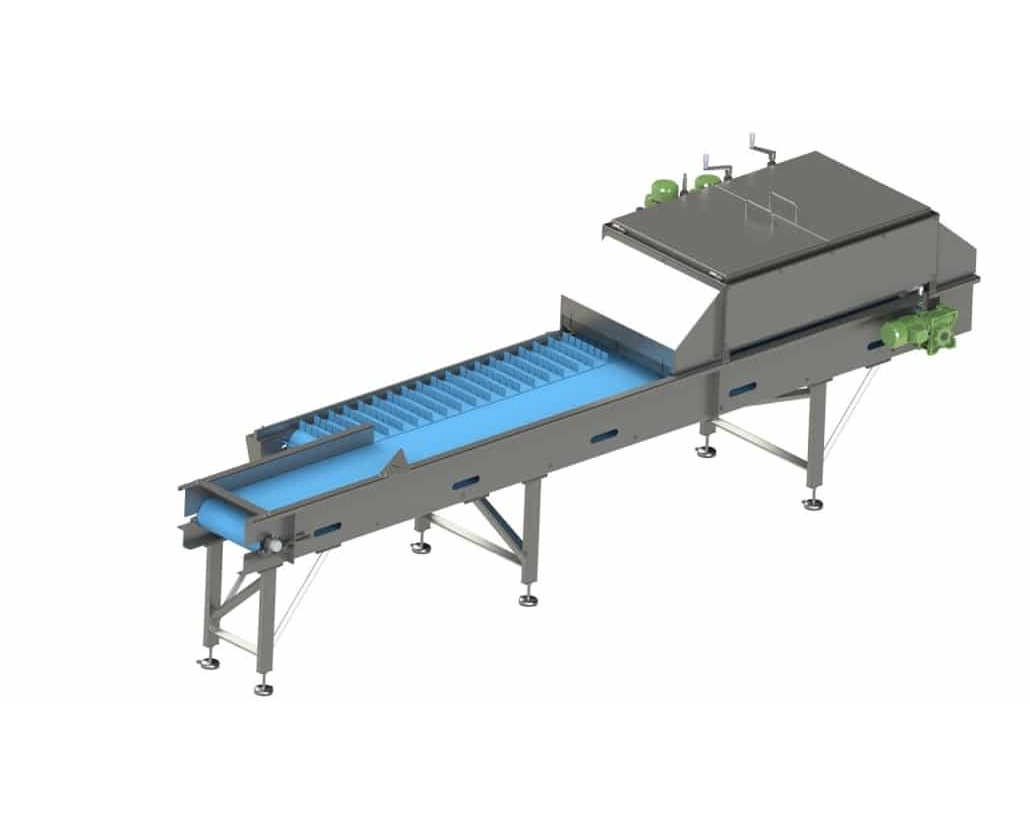

Topping, tailing and cutting

The Top/Tail and Plug-Cutting Machines - TTP is expertly designed for topping, tailing, and cutting long products like carrots, parsnips, corn, cucumbers, leeks, chicory, spring onions, and zucchinis into uniform pieces. The machine features a flat conveyor belt for product feed and a belt with flights where the products are precisely positioned for cutting. As the products are placed between the flights, they are transported to the first circular blade for cutting, with an adjustable guide allowing for top and tail sizes ranging from 0 to 40 mm. After decapitation, the products are moved to a set of circular blades to be cut into uniform pieces. For added versatility, an optional second set of blades can be installed to achieve different cutting sizes. The machine is designed with hygiene and efficiency in mind, featuring a waste chute for disposing of tops and tails, a hygienic control cabinet with emergency stop buttons, and an optional HMI for easy operation. Additionally, the capacity can be expanded by equipping the machine with two belts with flights on both sides of the conveyor belt and an extra-wide cutting unit, effectively doubling the throughput without requiring an additional machine.

Advantages of our Top/Tail and Plug-Cutting Machines - TTP

Adjustable top/tail size. Customizable guide for precise top and tail cuts.

Versatile cutting options. Multiple circular blades for uniform and varied piece sizes.

Hygienic design. Includes a waste chute and hygienic control cabinet with safety features.

Capacity expansion. Optional dual-belt and wide cutting unit to double capacity.

What our clients say

Contact us

Curious about the options, the performance of the machine, a price quote? Contact us to discuss your needs!

Contact information headquarters