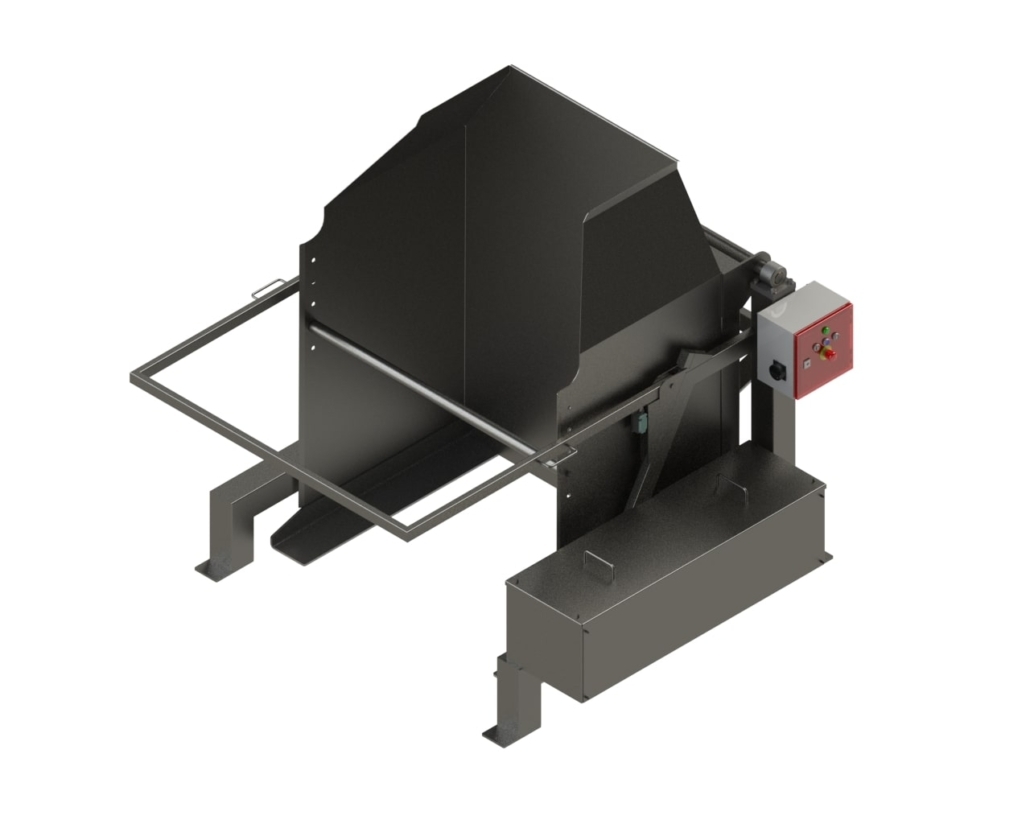

Box Tipper - KH

Quality and Innovation

by Marcelissen

Suitable for

Potatoes, root vegetables

Interested?

Get in touch with us

Quality and Innovation

by Marcelissen

Suitable for

Potatoes, root vegetables

Interested?

Get in touch with us

Streamline and optimize your production line

The Box Tipper - KH is used at the beginning of a processing line for product infeed. The machine is engineered to simplify handling for large, heavy boxes of root vegetables, especially beet roots and potatoes. With its robust construction and precision control, our box tipping solution offers a seamless way to unload produce with minimal manual effort and maximum protection for the product, helping you streamline your operations and enhance productivity.

It is fitted with the hydraulic system and control box on the right-hand side. For safety reasons, the control must be kept pressed down and the safety bar must remain closed before the box can be tilted.

Optionally, this box tipper can be extended to a fully automatic machine including PLC, sensors and wired remote control. The control panel is programmed in such a way that when the box is completely empty, it automatically tilts back and a lamp starts flashing. This means that the crate is empty and that it can be replaced by a new one.

With this fully automatic version, there is also a switch with different shaking positions. If the box is emptied slowly, it is always possible that some residual product remains in it. By shaking the boxes a few times, the residual product will come out.

Advantages of our Box Tipper - KH

Speeds up unloading, reducing manual labor and handling time.

Multifunctionality for feeding various products into a productionline beyond just potatoes.

Gentle tipping minimizes bruising, preserving produce quality.

Compatible with a bunker combined with a conveyor or screw for a smooth productflow.

What our clients say

Contact us

Curious about the options, the performance of the machine, a price quote? Contact us to discuss your needs!

Contact information headquarters