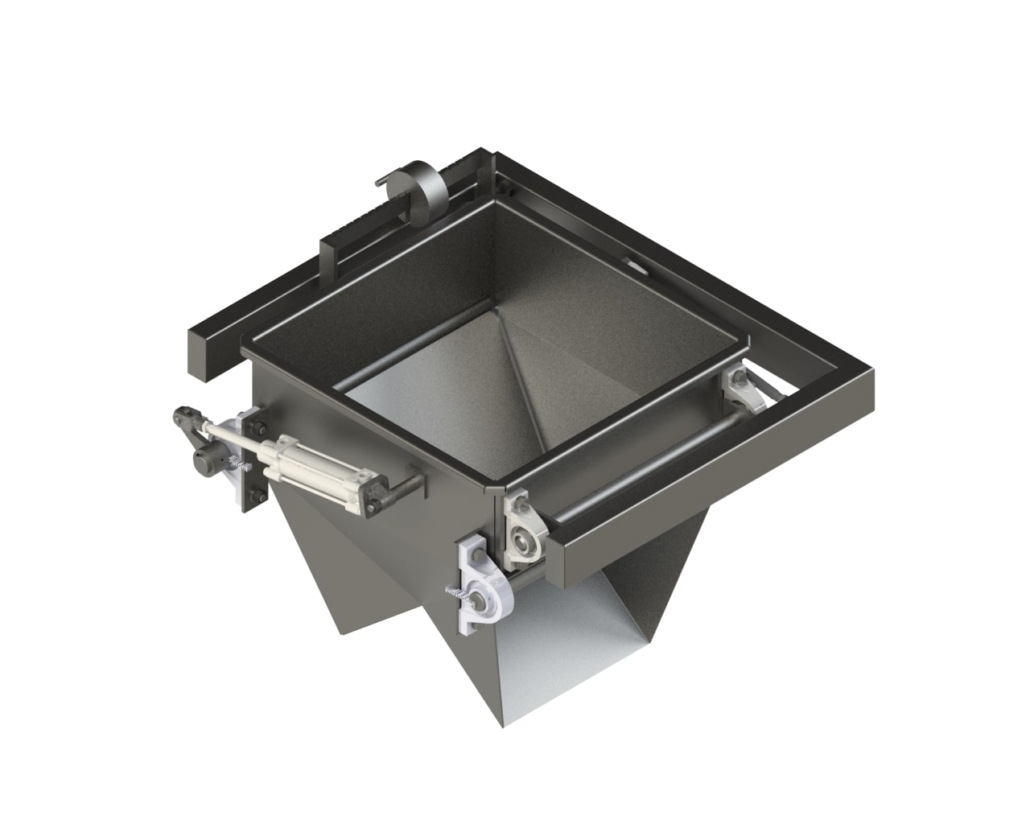

Double Weighing Hopper – AD

Quality and Innovation

by Marcelissen

Suitable for

Potatoes, root vegetables, fruit, pistachios

Interested?

Get in touch with us

Quality and Innovation

by Marcelissen

Suitable for

Potatoes, root vegetables, fruit, pistachios

Interested?

Get in touch with us

Advanced precision

The Double Weighing Hopper – AD is a precision-engineered solution designed to regulate and dose products into two adjacent batch peelers or scrapers, ensuring optimal efficiency and accuracy in your production line. Controlled by a PLC (programmable logic controller), this system allows operators to set a fixed weight in kilograms, tailored to achieve the best peeling or scraping results. A sensor within the hopper accurately registers the product weight, and once the desired amount is reached, an electro-pneumatically operated valve opens to release the product into the left or right bottom peeler or scraper. The system also features an automatic start/stop mechanism, streamlining the feeding process by automating the filling of the weighing hopper. This advanced functionality not only enhances precision in dosing but also significantly boosts the efficiency of your peeling or scraping operations, making it an ideal choice for industrial settings that demand consistent, high-quality results.

Advantages of our Double Weighing Hopper - AD

Precise dosing. Ensures accurate product dosing for optimal peeling or scraping results.

Enhanced efficiency. Automates product feed, increasing the efficiency of the peeling or scraping process.

Flexible application. Suitable for use with one or two peeling machines.

Automated operation. PLC control for easy setup and automated performance.

What our clients say

Contact us

Curious about the options, the performance of the machine, a price quote? Contact us to discuss your needs!

Contact information headquarters