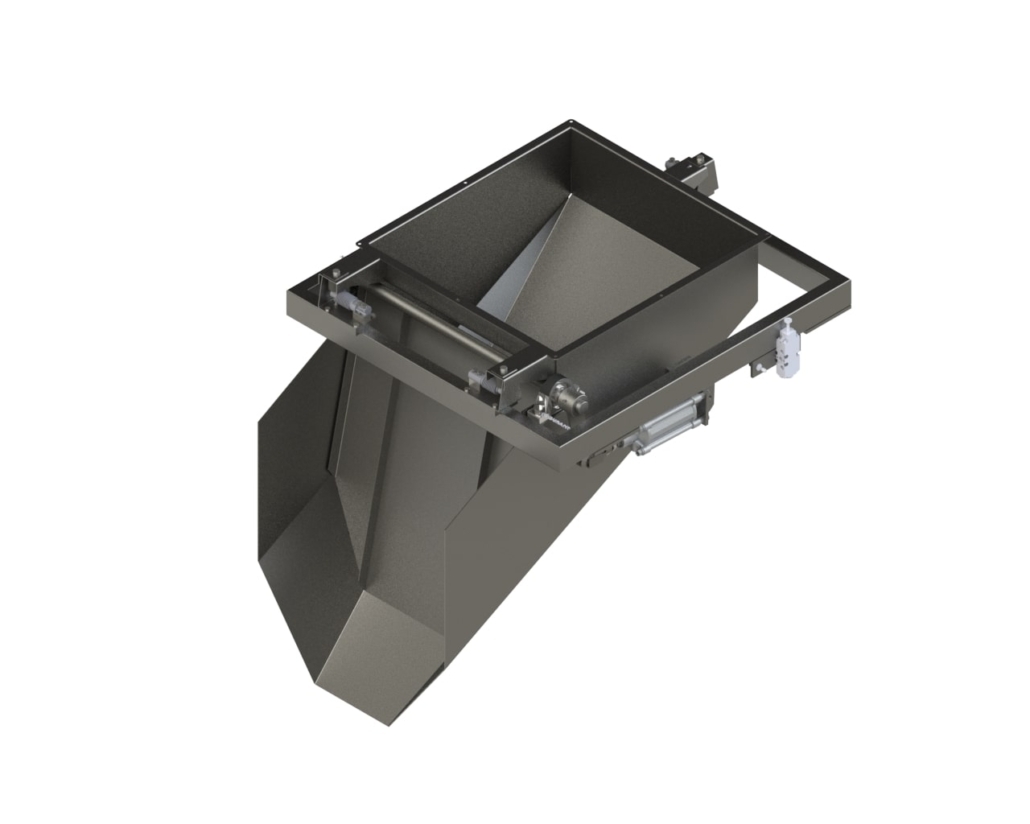

Weighing Hopper – A

Quality and Innovation

by Marcelissen

Suitable for

Potatoes, root vegetables, fruit, pistachios

Interested?

Get in touch with us

Quality and Innovation

by Marcelissen

Suitable for

Potatoes, root vegetables, fruit, pistachios

Interested?

Get in touch with us

Expert design for precise delivery

This dosing machine is expertly designed to deliver precise product dosing for one or two peeling machines, making it an essential tool for optimizing production lines. Specifically engineered for use with batch peelers, the system regulates product feed with remarkable accuracy. The machine is controlled by a Programmable Logic Controller (PLC), which allows operators to set the desired product weight within a preset range. As the product is loaded into the hopper, a sensor accurately measures the quantity, and once the target weight is achieved, an electro-pneumatically operated valve opens to discharge the product into the peeler. This automated process ensures that each batch is consistently dosed, reducing waste and enhancing efficiency in the peeling process. With its robust design and precise control, this dosing machine is ideal for industrial settings where reliability and accuracy are paramount.

Advantages of our Weighing Hopper - A

Precise dosing. PLC control and electro-pneumatic valve ensure accurate dosing to preset specifications.

Efficiency in production lines. Perfect for consistent dosing in peeling machines, optimizing production flow.

Automated operation. Reduces human error and maximizes efficiency through PLC automation.

Reliable performance. Designed for demanding industrial environments, ensuring consistent and precise operation.

What our clients say

Contact us

Curious about the options, the performance of the machine, a price quote? Contact us to discuss your needs!

Contact information headquarters