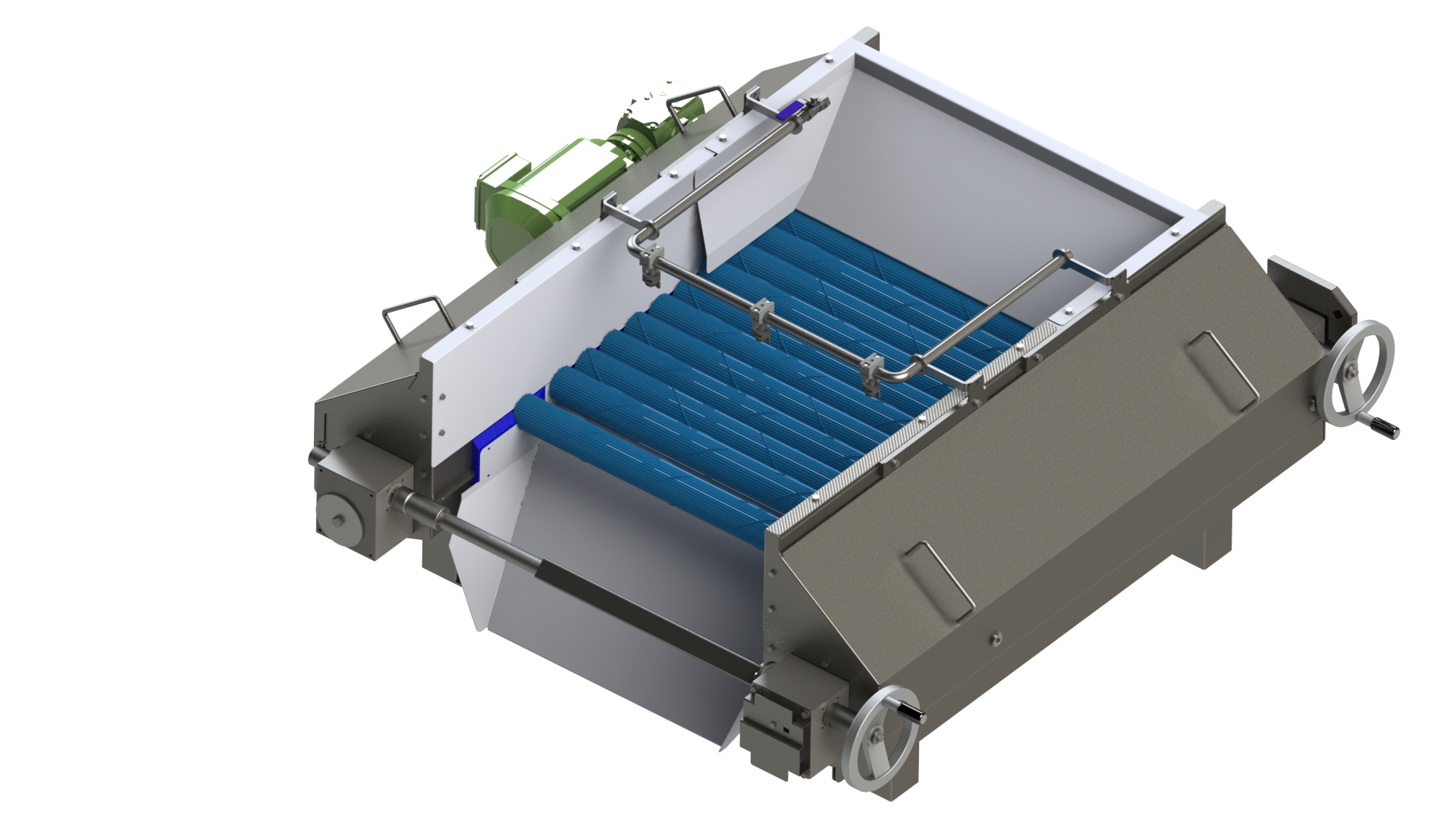

Split Sorter – SR2-S

Quality and Innovation

by Marcelissen

Suitable for

Potatoes, root vegetables, fruits, pistachio nuts.

Interested?

Get in touch with us

Quality and Innovation

by Marcelissen

Suitable for

Potatoes, root vegetables, fruits, pistachio nuts.

Interested?

Get in touch with us

The highest quality and accuracy

The Split Sorter - SR2-S is a machine meticulously designed to separate three different sorting sizes from each other. The most important advantage of this sorting machine is that the roller opening can be easily, quickly and precisely adjusted during the production process by means of a stainless steel adjustment box. This Split Sorter is an enhancement to Marcelissen's signature Sliver Remover, where even two ranges can now be set to sort.

The Marcelissen Split Sorter has the highest quality, accuracy and capacity in the industry. With these adjustable sorting sizes (during production) and its low maintenance it has been the market leader for decades. It is easy to clean and the minimum of wearable parts ensure only a minimum of downtime in your production process.

All Split Sorters are custom-engineered and made. We work closely with you to ensure our machines meet your needs and are produced according to your specifications. Co-creation is in our DNA and the basis of our success. Engineering and R&D are crucial for developing new products and processes. Our mission is to stay updated on food market trends to expand our machinery range. We consistently innovate to amaze both the market and our customers with reliable, innovative machines.

Advantages of our Split Sorter - SR2-S

Two adjustable ranges from 3 to 23 mm or 4 to 24 mm.

Top-notch accuracy and efficiency.

Easy and straightforward maintenance.

Durable construction using minimal wearable parts.

Efficient waste management.

What our clients say

Contact us

Curious about the options, the performance of the machine, a price quote? Contact us to discuss your needs!

Contact information headquarters