French Fries Line

How can we improve your process?

By offering complete processing lines for beets, we ensure high quality end products with maximum efficiency and minimum downtime. We are pleased to share our expertise with you to develop an optimal beet processing line tailored to your needs.

Beets are processed similarly to other root vegetables, using a comparable process line. However, at Marcelissen, we believe it is crucial to customize production lines to meet the unique wishes and needs of our customers. To guarantee high quality product, we offer the full range of machines to ensure a smooth production process.

Bunker with Outfeed Conveyor - BT

This machine is designed for product intake at the start of a processing line, potentially following a box tipper. It features an inclined conveyor belt with a chevron profile for efficient product feeding. Key features include an infeed hopper with a discharge conveyor, adjustable belt speed to ensure optimal outfeed, and availability in different widths to accommodate various applications. The machine ensures efficient and versatile product handling at the beginning of the processing line.

Technical details

Efficient production feed

Various applications possible

Adjustment with a frequency converter

Batch Peeler Machine - SKB

The Batch Peeler Machine SKB500 is a batch machine with an abrasive peeling disc of approximately 500 mm diameter. A well-dosed filling is essential for optimal peeling results. The machine operates electro-pneumatically via a PLC-controlled cabinet, with the peeling time and unloading time adjustable.

Technical details

Evenly peeled products

And performance of up to 500 kg/hr

Evenly peeled products

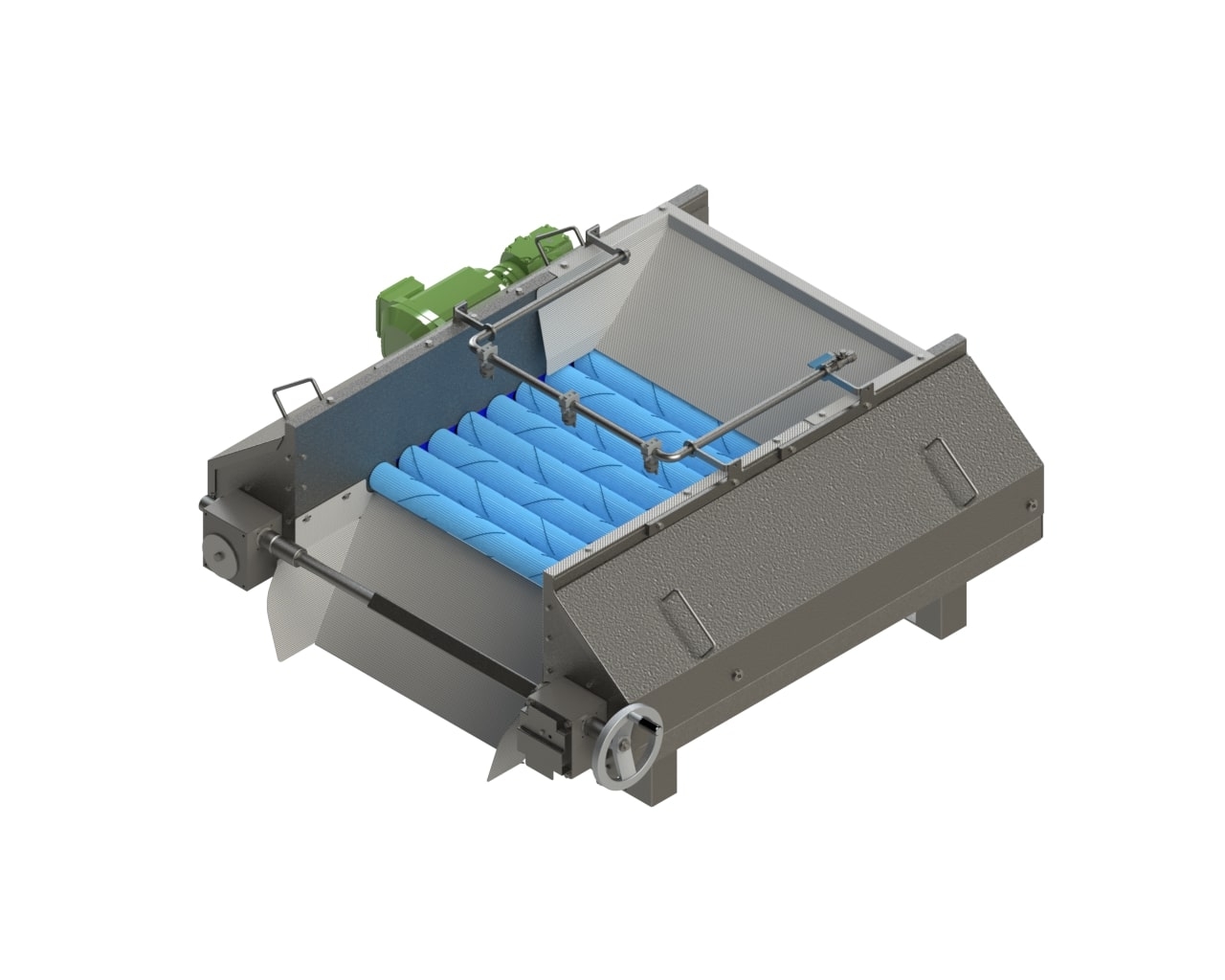

Drum Roller Peeler - SKR

The Drum Roller Peeler – SKR is engineered with abrasive linen rollers that form a rotating drum, ensuring efficient and thorough peeling of your root vegetables. The machine features a transport auger inside the drum to regulate transit time. The speeds of the rollers, drum, and auger are adjustable via frequency converters, allowing for precise control over the peeling process.

Technical details

High-quality output

Up to 7,500 kg/hr

For even peel

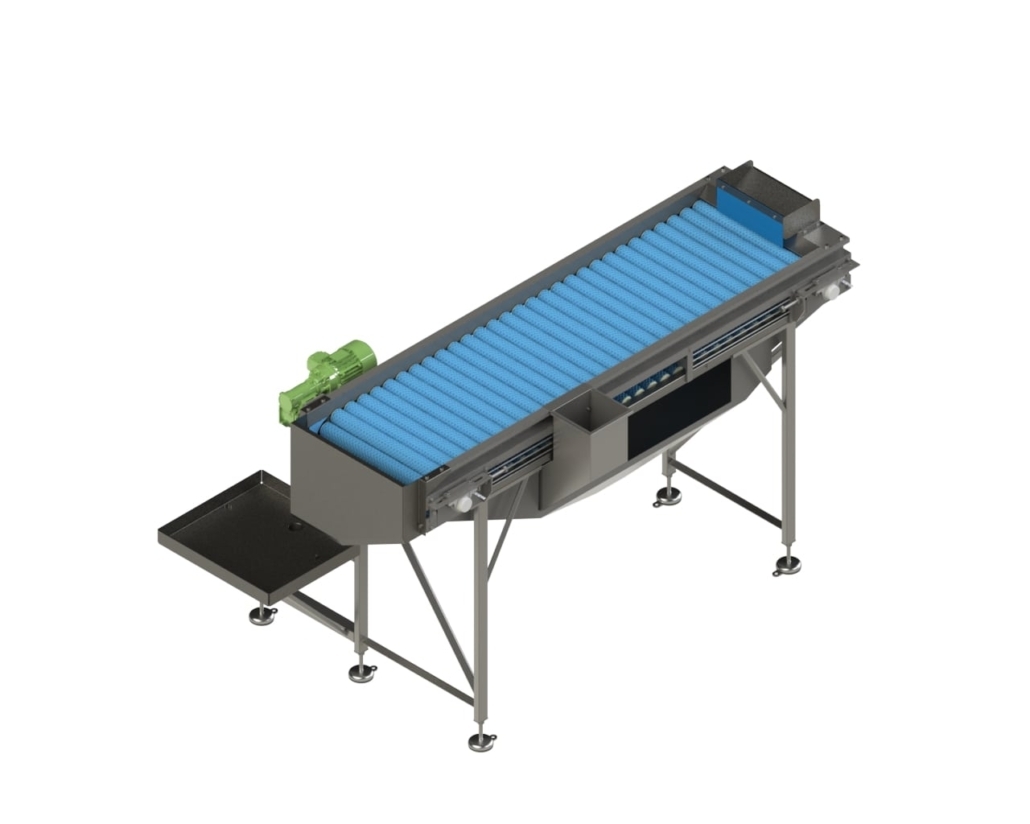

Roller Inspection Belt - IR

The Roller Inspection Belt - IR, also known as an inspection conveyor or roller sorting table, is designed for efficient inspection and sorting of root vegetables. Utilizing rotating rollers to turn and move the product forward, this machine ensures a thorough inspection process. Equipped with blue, food-approved rollers (RAL 5017), it provides a hygienic and safe environment for food handling.

Technical details

Accurate inspection for spotting defects

Designed for various types of products

For safe food handling

Hydro Cutter - SH

The Hydro Cutter by Marcelissen efficiently cuts potatoes into fries, wedges, cubes and slices. Changing the knife blocks takes less than a minute and, as with all other Marcelissen machines, maintenance is minimal. The Hydrocutter - SH is designed to effortlessly cut large quantities of potatoes (up to 15,000 kg/hr) into fries, wedges, and slices. Additionally, it can halve or quarter potatoes (lengthwise). The machine comprises five main components: a water tank, pump, venturi tube, cutting section, and decelerator.

Technical details

Up to 15,000 kg/hr

Cuts wedges, slices, parts and fries

Cutting process

Sliver Remover - SR2

Marcelissen’s signature Sliver Remover – SR2 is a machine meticulously designed for grading (too) thin pieces of potatoes and other root vegetables. This advanced sorter efficiently separates slivers, ensuring the highest quality in your final product.

The Sliver Remover is an original Marcelissen innovation and specifically designed for grading small pieces. With adjustable rollers the Sliver Remover sorts out small slivers of potato, peach and root vegetables.

Technical details

Up to 24 mm

Accurate, efficient and low maintenance

And straightforward maintenance

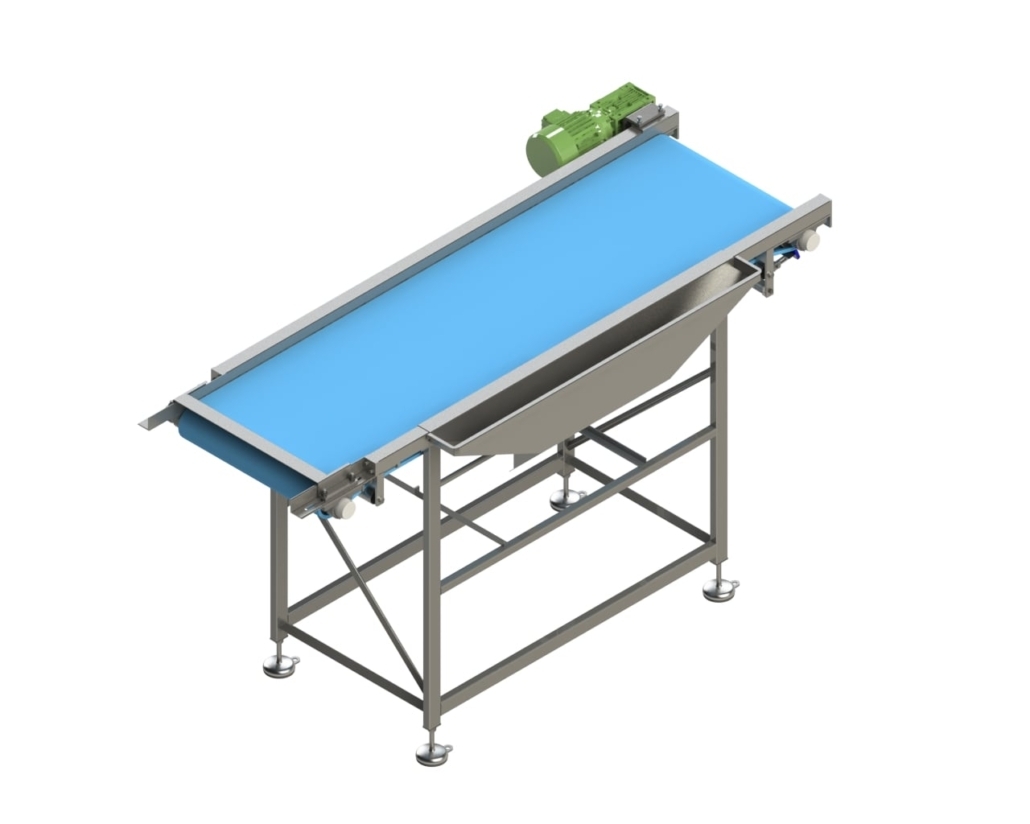

Inspection Belt - IB

The inspection conveyor is specifically designed for inspecting and sorting root vegetables, ensuring high-quality standards in your production line. This machine features a blue, food-grade belt, providing a safe and hygienic environment for food handling. Its straightforward design and ease of use make it an essential tool for efficient inspection processes.

Technical details

Simple belt frame design with a flat surface

Easy to clean, hygienic handling and minimal maintenance

To clean

The process

The end product dictates the design of a French Fries line. At Marcelissen, we offer a comprehensive range of equipment and configure it to achieve your needs and product specifications. This ensures the optimal processing line for your specific situation. Despite our flexibility in determining and manufacturing the ideal solution, we employ a standardized approach to identify requirements:

Our expertise

Co-creation

As a family-owned company we value cooperation and the mutual trust that comes with it. We work with you to achieve mutual goals.

Custom-made solutions

Our experience translates into commitment, trust and a deep knowledge of the technology, the market and the needs our customers face.

Highest quality

The quality of your product depends on the quality of our machines. All of Marcelissen’s machines are made with the best quality materials and engineering.

Innovative technologies

Innovation is key. The Sliver Remover is a Marcelissen innovation, for instance. By implementing the latest technology we stay ahead and deliver high quality and innovative machines to the market.

Reducing waste

All our machines are made with efficiency in mind. Reduce both food waste and water consumption and increase efficiency at the same time.

What our clients say

Interested in how we can help you?

Whether you are cutting, peeling, sorting, washing or transporting potatoes, fruits, root vegetables or nuts, at Marcelissen we have the solution. With innovative food processing machines in our portfolio we never have to say no to any challenge.