Slitmaster 105

Quality and Innovation

by Marcelissen

Suitable for

Potatoes

Interested?

Get in touch with us

Quality and Innovation

by Marcelissen

Suitable for

Potatoes

Interested?

Get in touch with us

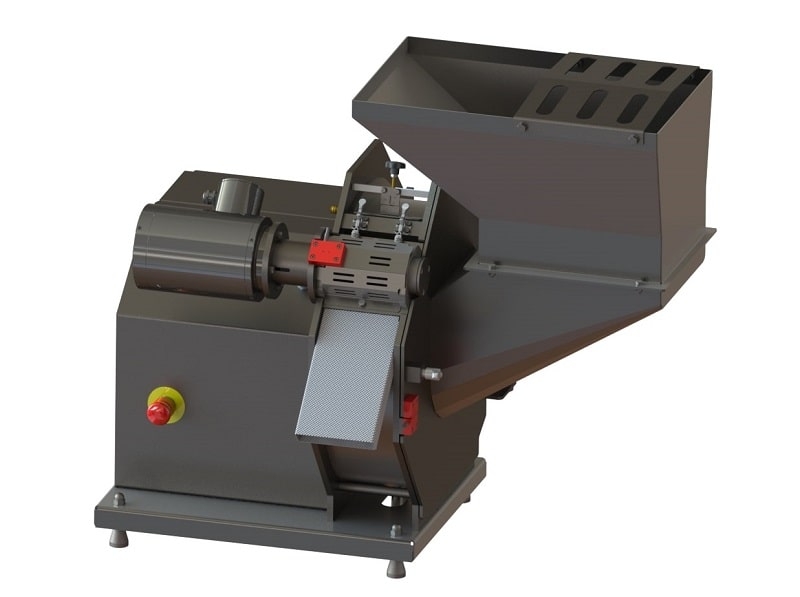

Ultimate fries cutting machine

The Slitmaster 105 is the ultimate solution for efficiently cutting French fries! Engineered with state-of-the-art technology and innovative features, this machine is a game-changer for businesses looking to optimize their cutting process and maximize efficiency. The Slitmaster 105 is capable of processing potatoes with a diameter of up to 105 mm, making it perfect for producing large French fry potatoes.

With the Slitmaster series Marcelissen offers the ultimate cutting machine for fries. Optimize your cutting process by maximizing efficiency using advanced technology and innovative features. The Slitmaster machines process potatoes with great precision to cut perfect straight french fries. All machines are CE Certified and are fully compliant with the latest safety regulations. Look no further than the Slitmaster series to provide the best and most efficient cutting process in the industry.

Engineering and R&D are crucial for developing new products and processes. Our mission is to stay updated on food market trends to expand our machinery range. We consistently innovate to amaze both the market and our customers with reliable, innovative machines.

Advantages of our Slitmaster

Process potatoes with a diameter up to 105 mm.

Quick switching between cutting sizes.

Consistently cutting the longest fries to minimize waste.

Adjustable to cut fries with a width 7 to 14 mm.

What our clients say

Contact us

Curious about the options, the performance of the machine, a price quote? Contact us to discuss your needs!

Contact information headquarters