Zoo Antwerpen

350+

Employees spread across multiple zoos

400kg

Animal food per day

Top 10

Most beautiful zoo in Europe

Interested?

Get in touch with us

350+

Employees spread across multiple zoos

400kg

Animal food per day

Top 10

Most beautiful zoo in Europe

Interested?

Get in touch with us

Optimizing the animal kitchen with minimal payback time

The Koninklijke Maatschappij voor Dierkunde Antwerpen (KMDA) is a zoological society that was founded on July 21, 1843, and from this the ZOO Antwerpen immediately emerged as the first and oldest zoo in Belgium.

In 1956, the KMDA purchased the Planckendael estate in Muizen near Mechelen. Initially this animal park was used as an outdoor enclosure for animals from Antwerp Zoo, but over time the KMDA invested more and more in Planckendael so that today it is a modern and fully-fledged zoo.

Antwerp Zoo and Planckendael Zoo are therefore both part of the KMDA, also one of the oldest organizations in Belgium. The three core values that the organization focuses on are applied in both zoos: conservation, sustainable enterprise and education. The Centre for Research and Conservation is also part of the KMDA. It is an in-house research center for nature conservation that has already received several awards and mainly carries out research at Antwerp Zoo and Planckendael, but also abroad. The KMDA is therefore highly regarded in the international zoo world.

The problem

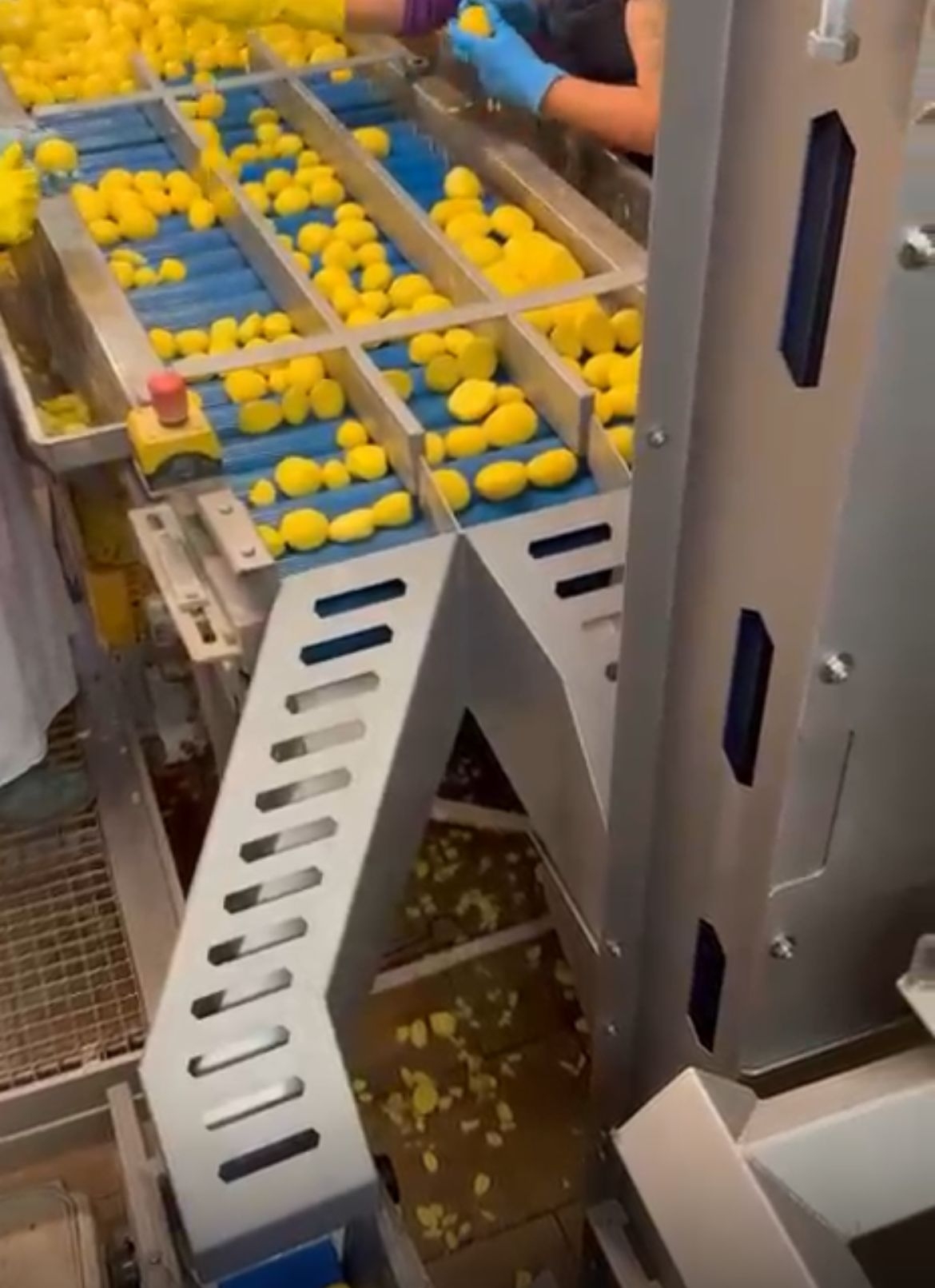

In both the animal kitchens of ZOO Antwerpen and ZOO Planckendael, at the beginning of 2022, all fruit and vegetables for animals were still being cut up manually, or with a small-scale kitchen appliance, every day before it went to the animals. To make this process not only more efficient but also less labor-intensive, the KMDA went in search of a cutting machine suitable for commercial kitchens and the catering industry.

Through our experience and reputation at AAP Foundation (who also use a Slitmaster slicer in their animal kitchen) KMDA quickly came to us when they wanted to further professionalize.

The solution

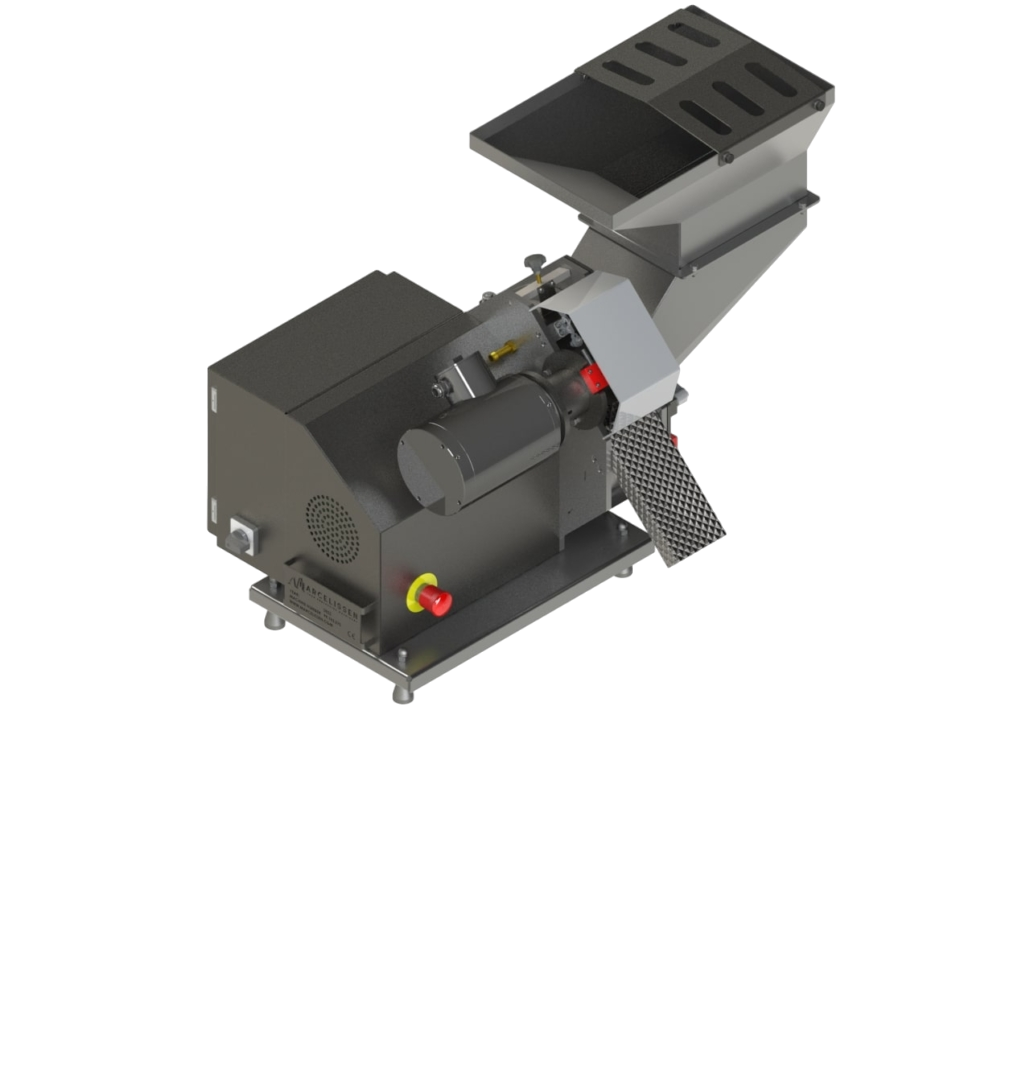

KMDA came to us with the question if we could supply a suitable industrial slicer. After a brief inventory of the requirements, the right choice was quickly made: it had to be a Slitmaster slicer. And specifically our newest type; the Slitmaster 85.

The Marcelissen Slitmaster 85 has been specially developed for cutting French fries and/or slices from potatoes and other vegetables. Due to the unique design of the rotor, the Slitmaster 85 always cuts the longest possible ‘sticks’ and therefore minimizes the amount of waste and short pieces. Furthermore, we have ensured that our customers can cut discs with a thickness of 7 – 14 mm with this Slitmaster 85. For this, only one disc knife is needed. As for cutting fresh fries, this is possible in thickness varying from 7 – 14 mm. Per millimeter, a separate bar knife is required as the number of knives can vary per thickness.

The simplistic yet inventive design makes the slicer very easy to use and maintain. Take for example changing the knife roll set, this is possible in less than a minute due to the simple ‘quick-release’ system.

In order to meet all applicable food safety requirements, the Slitmaster 85 is largely constructed of AISI 304 stainless steel and equipped with a POM plastic rotor. In addition, this slicer has the necessary CE safety features such as an emergency stop circuit and magnetic switches.

The result

In May 2022, we delivered two Slitmaster 85 slicers including a custom-built undercarriage to both zoos. Because of the mobile undercarriage and the stand-alone construction of the machine, it can easily be moved towards the kitchen rinsing area when they want to clean the machine or to the workshop when they want to perform minor maintenance.

"These machines have enabled us to use our employees many times more efficiently. And that with a payback period of less than 3 months!"

Coördinator Department Animal Nutrition

The impact

Instead of 16 hours a day, KMDA employees now spend only 6 hours a day cutting vegetables and fruits for the animals. Currently they are cutting white cabbage, red cabbage, zucchini, apples, carrots, turnips, radish, parsnips, fennel and cucumber, among others, mainly in slices.

Both zoos have been working with the machines for two months now and have already earned back their investment by saving time, that’s what we call an efficient way of working!

More client cases

Farma Pour

Farma Pour s.r.o., a small-scale, warm-hearted potato processor in the Czech Republic, is a fine example of a company with strong local roots and ambitious growth plans. In addition to selling high-quality potato products, they run a charming farm shop where they also offer their own dairy products, such as cheese and yogurt, to the local community.

Vätternpotatis AB

Vätternpotatis AB, located on the shores of the enchanting Lake Vättern, is the proud source of the beloved Vättern potatoes. The fertile fields near this Swedish lake provide the perfect environment for growing potatoes. Cultivation is managed by carefully selected, IP-certified growers who supply the exceptional potatoes that eventually find their way into modern kitchens, where they are processed into high-quality products.