Vätternpotatis AB

2023

Customer at Marcelissen

2

Optical Sorter Mechanical delivered

Interested?

Contact us!

2023

Customer at Marcelissen

2

Optical Sorter Mechanical delivered

Interested?

Contact us!

Innovative machines for Vätternpotatis AB

Vätternpotatis AB, located on the shores of the enchanting Lake Vättern, is the proud source of the beloved Vättern potatoes. The fertile fields near this Swedish lake provide the perfect environment for growing potatoes. Cultivation is managed by carefully selected, IP-certified growers who supply the exceptional potatoes that eventually find their way into modern kitchens, where they are processed into high-quality products.

Founded in 1964 as Hästholmens Potatisprodukter, the company has grown into a reliable player in the potato processing industry. With products such as Minutpotatis and the unique Big Bag, they have firmly established themselves as an innovative force. The acquisition by Wernsing Feinkost GmbH in Germany in 2008 opened new opportunities for the company.

With a strong focus on sustainability and local cultivation, the company ensures that its products meet the strict requirements set by the Swedish Competition Authority (KKV). One of their key quality guarantees is that the products are completely free of sprout inhibitors and growth regulators, underscoring their commitment to healthy and natural products.

The problem

The outdated optical sorting machines no longer met the speed and accuracy demands. They were antiquated and needed to be replaced with modern technologies. Additionally, manual work was still required after sorting, which led to higher labour costs and delays in the process.

The solution

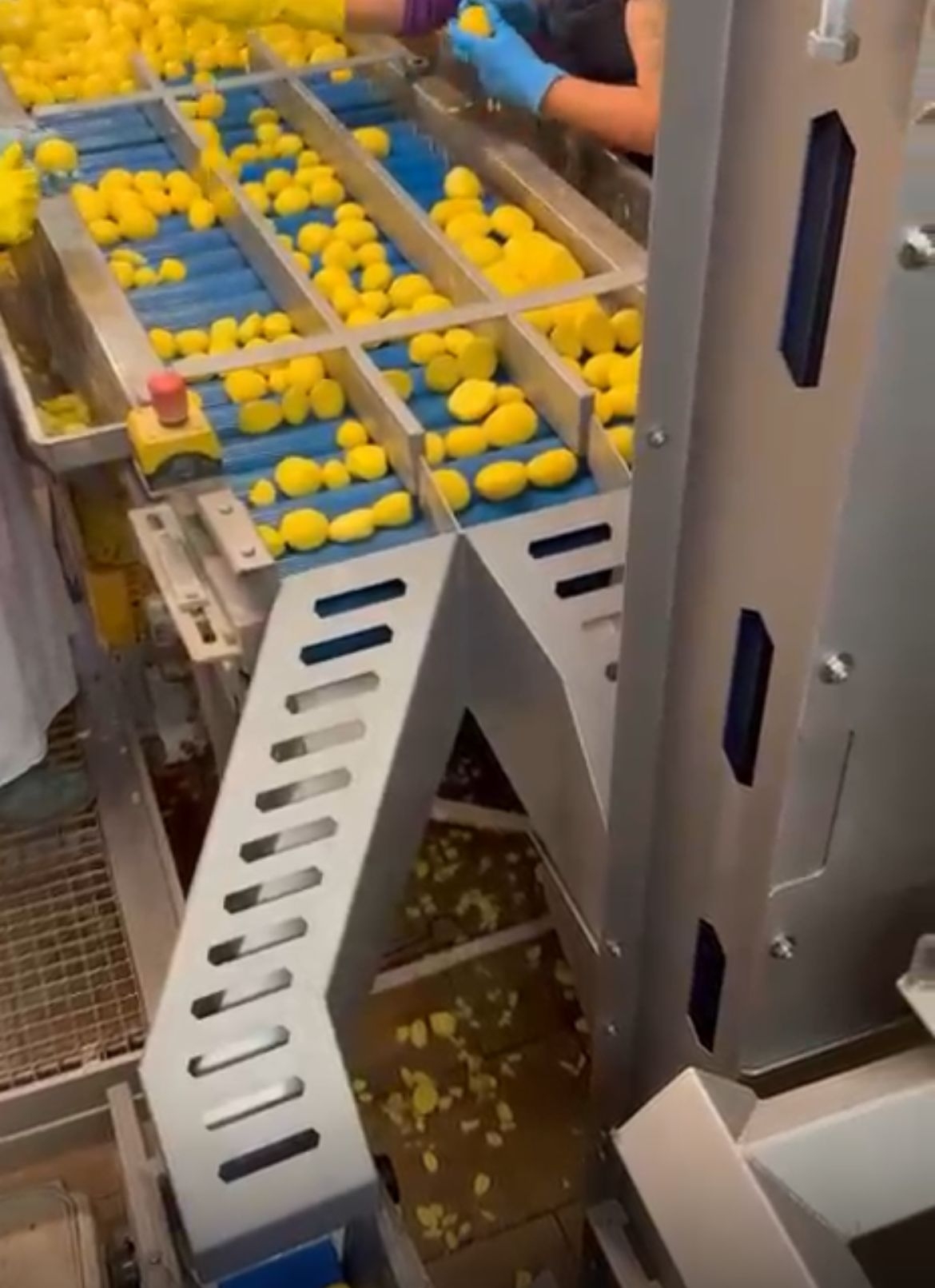

Thanks to the strong relationship between parent company Wernsing Feinkost and Marcelissen, we had the opportunity to offer a solution. After careful consideration, Vätternpotatis decided to partner with Marcelissen. Our optical sorting machine was specially developed to process both peeled and unpeeled potatoes. The newly placed sorters are the most accurate on the market. With four outlets per machine, they distinguish potatoes based on defects, colour, size, shape waste, dents and shadow. The result is a good flow with less than 1% defective products. The new sorting machines are installed 3 metres high on a large 60-square-metre platform, with 40 square metres reserved for movement around the machines and the remaining 20 square metres allocated to the machines themselves. The system was expanded with multiple transport connections for the supply and distribution of potatoes and the flow of sorted potatoes.

Advantages:

Efficiency: Using an advanced camera system, this machine evaluates defects, colour, size, shape and waste.

Sustainability: Built for long-term use in industrial environments, with a durable construction and minimal wear parts.

Ease of maintenance: Quick cleaning and easy part replacement. Wear parts are easily accessible and interchangeable with pre-assembled new parts, minimising downtime.

Hygiene: The machine is equipped with a self-cleaning system.

The result

Although Vätternpotatis AB handles the maintenance of the machines in-house, the company has also entered into an inspection and support contract with Marcelissen. Marcelissen visits the company in Sweden twice a year for inspections and advice to ensure the machines continue to perform optimally. Additionally, with remote support, we can monitor the sorting quality and intervene when necessary.

Key benefits at a glance:

Improved product quality and precision in potato sorting.

Avoidance of manual inspections, saving on labour costs.

Faster turnaround times and more flexible production capacity.

Continuous support from Marcelissen for optimal machine performance.

The impact

This is undoubtedly the most advanced and precise sorting system we have ever built. What seemed like an almost impossible task at the outset was eventually realised through streamlined collaboration. It was an educational project in which both parties exchanged valuable knowledge. Without the help of the eager and dedicated employees of Vätternpotatis, combined with the expertise and commitment of our own colleagues, we would not have been able to achieve such a high level of sorting quality.

The client is extremely satisfied and has since become one of our regular reference visits for optical sorters. This not only highlights the quality of our products but also the trust customers have in us. With Marcelissen’s new sorting machines, Vätternpotatis AB is ready to maintain its high-quality standards and innovate as it moves into the future.

With an impressive capacity of up to 90,000 potatoes per machine per hour, our two optical sorters together process as many as 180,000 potatoes per hour. It is a skilfully designed machine that sorts both peeled and unpeeled potatoes. After the evaluation by the 360° camera system, the potatoes are automatically separated, ensuring that only the best potatoes continue down the production line.

Why choose the Optical Sorter?

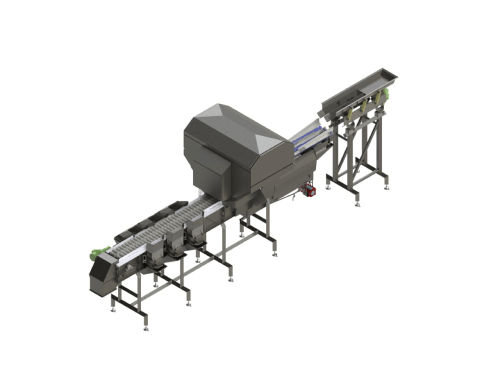

The Optical Sorter Mechanical – SOM is an expertly engineered machine for the optical sorting of both peeled and unpeeled potatoes. This advanced system evaluates defects, colour, size, shape, and waste, ensuring that only the highest quality potatoes continue through your processing line. It is equipped with a dosing unit, roller belt, camera unit, and ejection zone – each designed for optimal performance.

Flexible and advanced

One of the key advantages of our Optical Sorter is its flexible output configuration, which typically includes outlets for good product, waste/rejected product, and overflow for double peeling or reprocessing. The machine also features an advanced spray system for continuous cleaning of the roller belt, ensuring optimal hygiene standards. With an impressive capacity of up to 90,000 potatoes per hour, it delivers exceptional efficiency, adaptable to varying fill rates and potato weights, making it an indispensable tool for large-scale processing operations. All Optical Sorters are custom-designed and manufactured. We work closely with you to ensure our machines meet your needs and are built to your specifications. Co-creation is in our DNA and forms the foundation of our success.

Advantages of our Optical Sorter Mechanical

Precise sorting.

Efficient cleaning system.

Optimal hygienic design.

Flexible output configuration.

More client cases

Farma Pour

Farma Pour s.r.o., a small-scale, warm-hearted potato processor in the Czech Republic, is a fine example of a company with strong local roots and ambitious growth plans. In addition to selling high-quality potato products, they run a charming farm shop where they also offer their own dairy products, such as cheese and yogurt, to the local community.

Reno LLC

Reno LLC is a potato processing company rooted in the outskirts of Kyiv, Ukraine. After a turbulent period, their factory needed to be rebuilt to restart production. With resilience and determination they have made a fresh start. During this process they searched for a new processing line for their potatoes.