Smart expansion: greater product diversity for Farma Pour thanks to custom engineering

Farma Pour s.r.o., a small-scale, warm-hearted potato processor in the Czech Republic, is a fine example of a company with strong local roots and ambitious growth plans. In addition to selling high-quality potato products, they run a charming farm shop where they also offer their own dairy products, such as cheese and yogurt, to the local community. This customer, who was already very satisfied with their first Marcelissen peeling line, turned their vision of expansion into reality by investing in a smart extension of the existing line.

The challenge

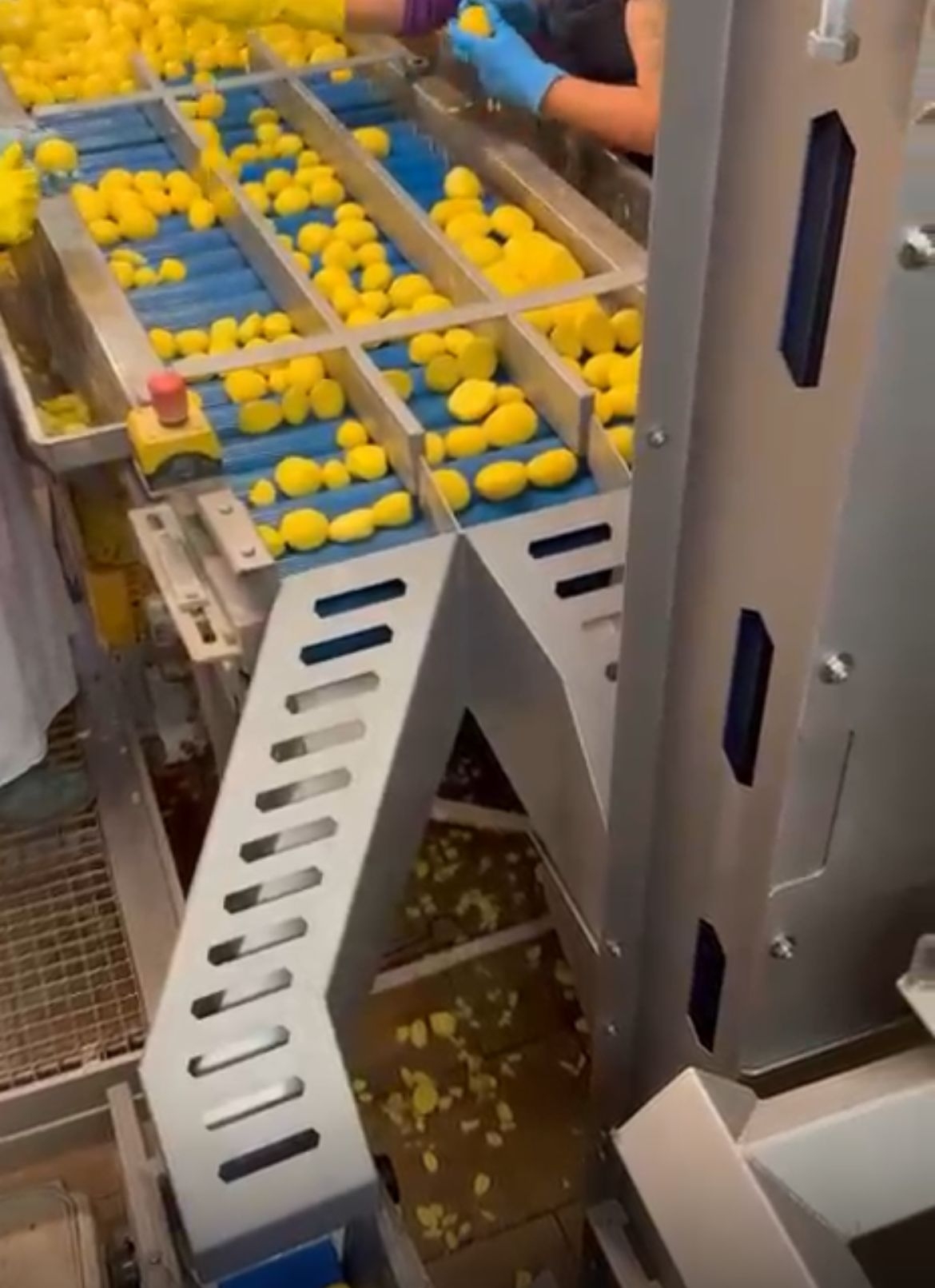

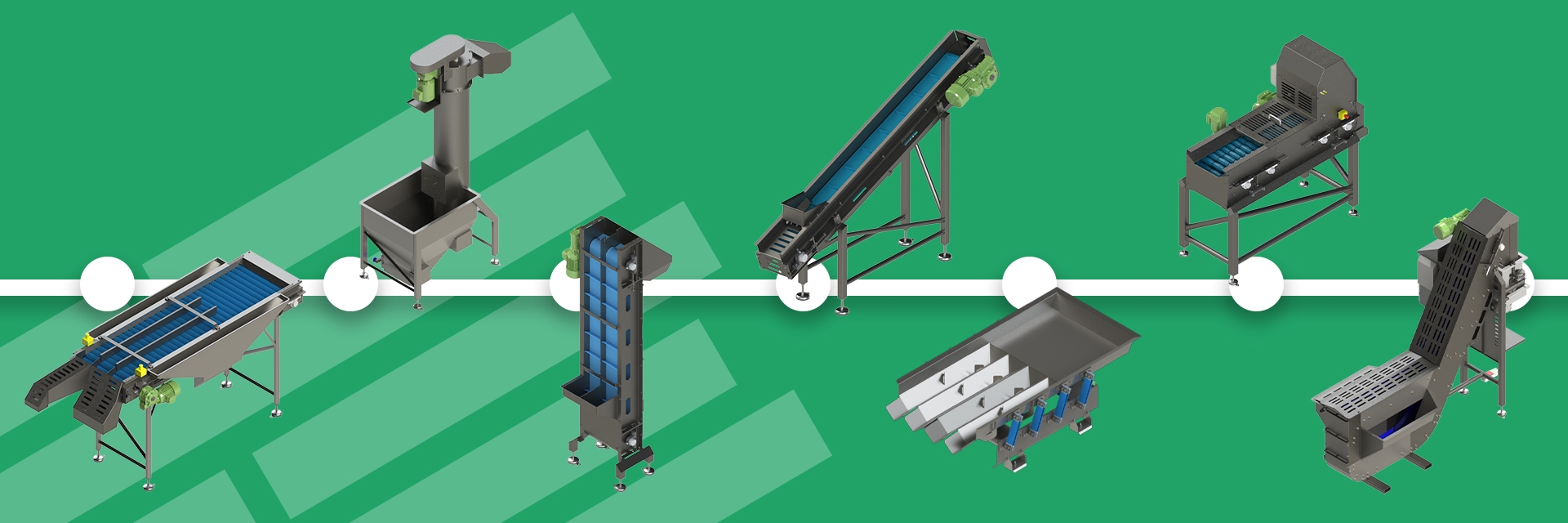

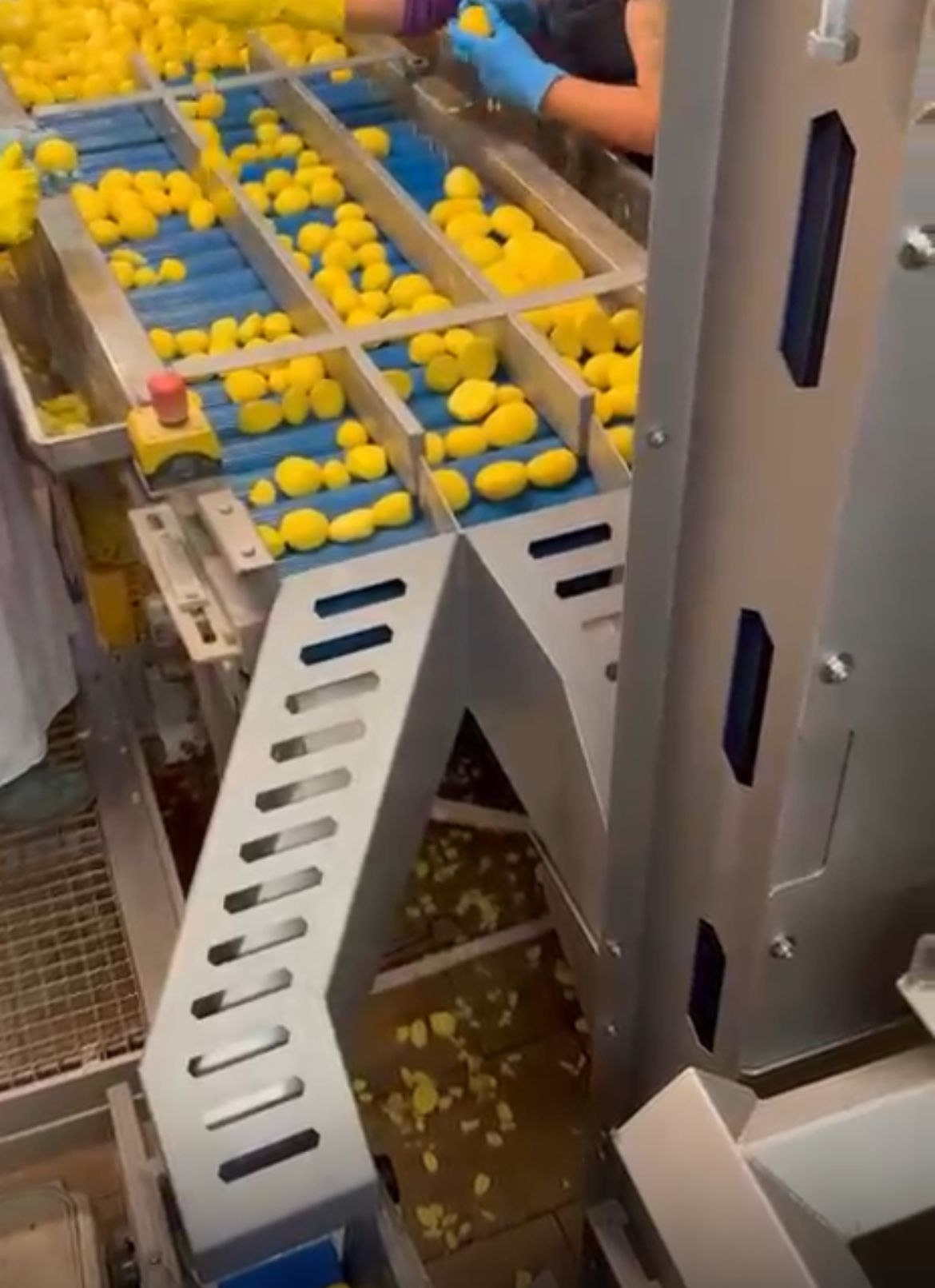

The initial peeling line, supplied by Marcelissen in 2023 (consisting of an Conveyor with receiving Hopper (TB), Abrasive Batch Peeler (SKB500), Knife Batch Peeler (SMB500), Conveyor with receiving Hopper (TB), Roller Inspection Belt (IR) and Buffer Conveyor with Automatic Weigher (AEBNT)), enabled Farma Pour to move from selling washed potatoes to successfully selling peeled potatoes.

This success led to a new challenge: diversification of the product range. To meet growing demand from nearby industrial kitchens, hospitals and schools, Farma Pour wanted to supply cut potato products in halves and quarters.

The main obstacle was the limited physical space in the existing production facility. A completely new cutting section with proper pre-sorting had to be integrated without disrupting the flow of the current line and within very tight dimensions.

The solution

To meet this customer requirement, Marcelissen realized a clever, customer-specific extension that fits seamlessly between the existing Roller Inspection Belt (IR) and the Buffer Conveyor with Automatic Weigher (AEBNT). This project required precision engineering and smart customization.

The new machines, ensuring flexibility and product diversity, are:

Screw Destoner VOS400: Strategically placed at the front of the line, this robust machine removes stones (and other contaminants) from the unprocessed product, minimizing downtime and protecting the service life of the critical peeling and segmenting machines.

Vertical Conveyor T400: Directly after the current Roller Inspection Belt (IR), the T400 collects and distributes the manually sorted potatoes into their respective processing lanes (medium and large) towards the segmenting machine.

Conveyor T200: This small bypass ensures that the smallest potatoes are guided directly from the inspection belt to the Automatic Weigher (AEBNT). This prevents unnecessary processing through the segmenting machine, increasing efficiency and safeguarding product quality.

Vibrating Infeed Feeder TVV2: Ensures correct feeding and even distribution of the different potato lanes into the segmenting machine.

Segmenting Machine D4/2: The heart of the expansion. This machine cuts the potatoes into halves or quarters, depending on size. It enables Farma Pour to supply a wide range of cut products and is equipped with upgraded sensors to optimize cutting accuracy.

Unique customization

The most distinctive feature of this installation is the fully customer-specific three-lane system. Employees at the roller inspection conveyor divide the potatoes into three size categories: small (bypass), medium (halving) and large (quartering). This smart design ensures optimal processing of every product and enables the customer to meet the desired specifications for all cut products. The frames and conveyor belts were fully custom-designed to fit exactly within the limited available space.

The result

The strategic expansion has been a great success. Farma Pour can now offer a much broader and more diverse product range, from peeled potatoes to perfectly halved and quartered products. The flexible, space-saving design has significantly increased productivity without the need for a new production hall. The addition of the Screw Destoner VOS400 at the start of the process has directly contributed to improved reliability and extended service life of the entire line.

The customer once again expressed high satisfaction with the collaboration. Choosing Marcelissen was a logical continuation of their previous positive experience:

"Mr. Pour is very satisfied, the daily capacity will certainly increase which is great!" — Pavel Krupa, our Sales Agent from the Czech Republic.

Although Farma Pour performs regular maintenance in-house, Marcelissen is always available with remote service support for software and electronic issues, ensuring process continuity.

The impact

The impact of this investment goes beyond increased production capacity alone.

The ability to supply cut potato products to large-scale users opens up an entirely new market for Farma Pour, leading to a faster return on investment (ROI) and further sustainable growth. As a local potato farmer with a strong commitment to the region, this expansion also allows Farma Pour to supply larger volumes of high-quality potato products more quickly to local schools and hospitals, directly contributing to improved nutritional quality within the community.

This renewed confidence, stemming from earlier positive experiences with Marcelissen, has resulted in a complex, custom-built system that proves that even the biggest ambitions can be realized in the smallest spaces.

Increase your capacity and product range. Contact us today for an efficient solution!

More news

09-12-2025

2025 in retrospective by Managing Director Jos Derijk

Managing Director Jos Derijk reflects on 2025.

17-12-2024

2024 in retrospective by Managing Director Jos Derijk

It is the time of the year again to reflect on 2024.

15-08-2024

A behind-the-scenes look at... HR Department

Beyond every machine there are hours of work. It is essential that everyone on the team feels right to perform optimally.