Processing potatoes more efficiently

Because great chips demand great machinery.

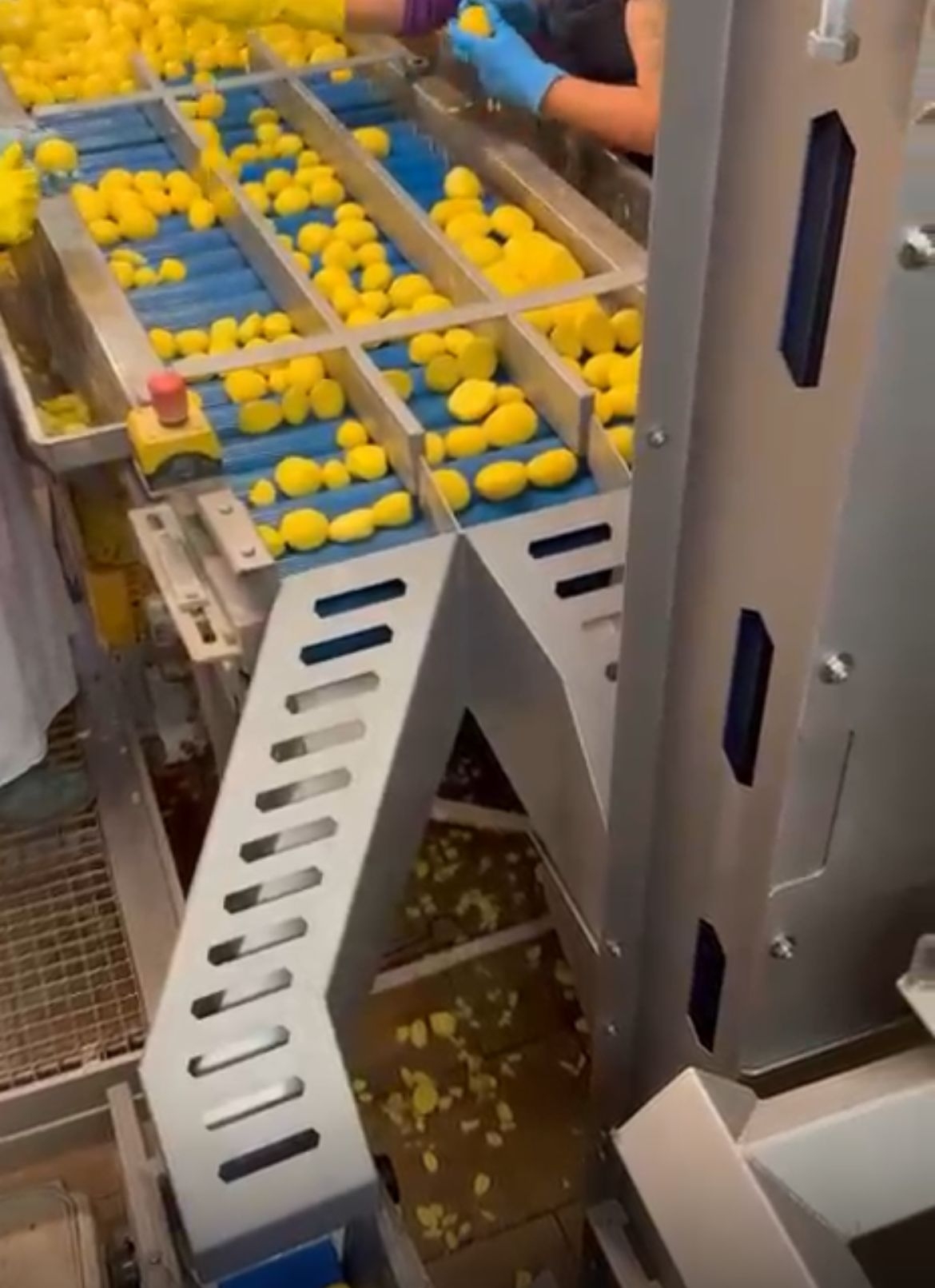

Consistency matters: automated and high quality

In the UK, chips aren't just food, they are a national treasure. At Marcelissen, we help food processors meet the highest standards with innovative machinery designed for precision, efficiency and sustainability. Food processing machines from Marcelissen allow for automation while keeping the highest quality. From peeling to cutting, our custom-made solutions ensure the perfect chip every time.

Our machines are designed for efficiency: reducing food waste and water usage while getting the very best out of every potato. By cutting lengthwise, we create premium chips and maximise yield. Less waste and more to taste!

Whether you're producing traditional chips, gourmet fries or specialty cuts, our equipment guarantees consistency and maximises product yield. Because every great chip starts with the right machine.

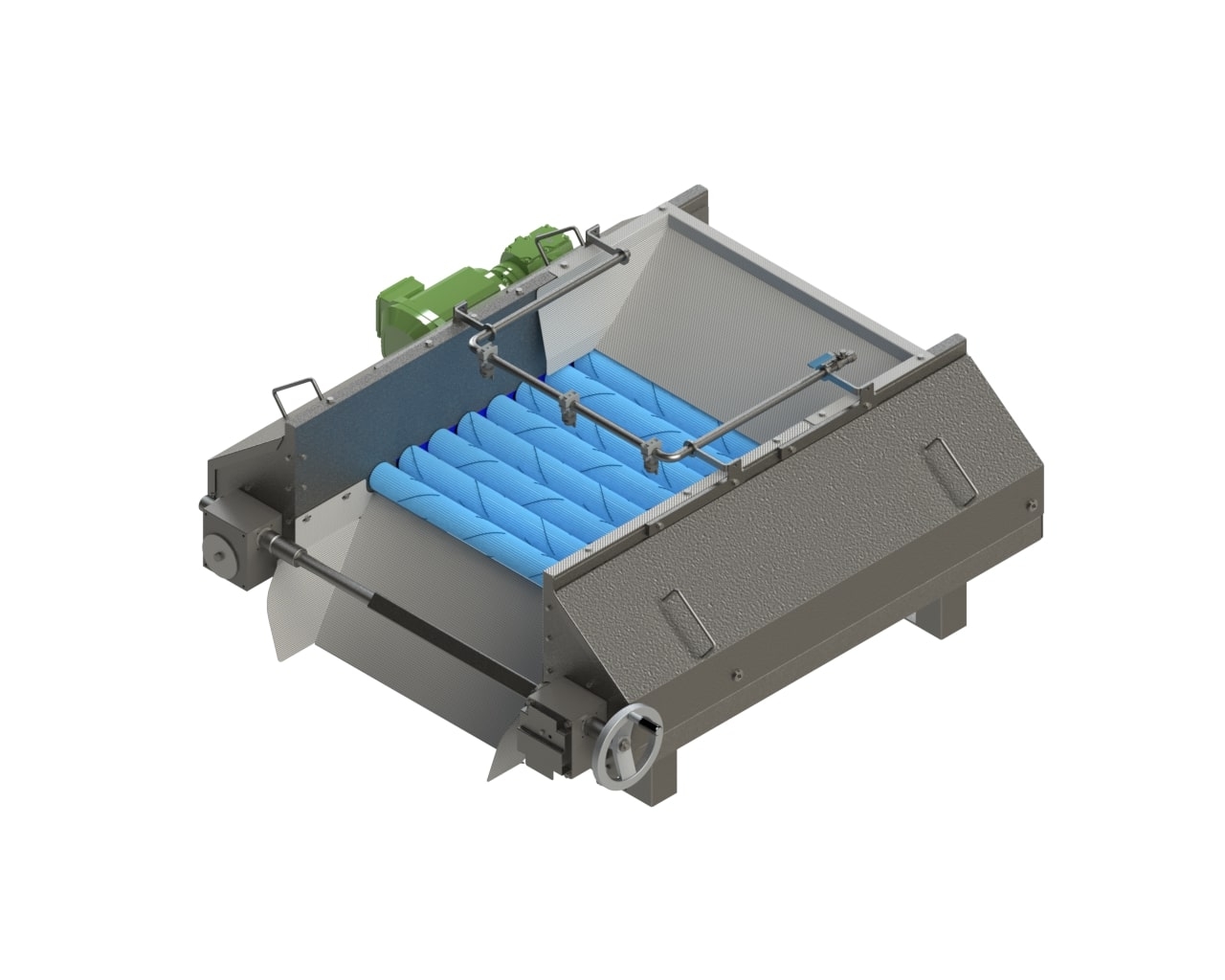

For over 75 years, Marcelissen has supported the potato processing industry with high-end, tailor-made machinery. Our Sliver Remover and Slit Master are perfectly suited to expand your product range, automate your process and reduce waste all along.

Why choose Marcelissen?

Co-creation

As a family-owned company we value cooperation and the mutual trust that comes with it. We work with you to achieve mutual goals.

Custom-made solutions

Our experience translates into commitment, trust and a deep knowledge of the technology, the market and the needs our customers face.

Highest quality

The quality of your product depends on the quality of our machines. All of Marcelissen’s machines are made with the best quality materials and engineering.

Innovative technologies

Innovation is key. The Sliver Remover is a Marcelissen innovation, for instance. By implementing the latest technology we stay ahead and deliver high quality and innovative machines to the market.

Reducing waste

All our machines are made with efficiency in mind. Reduce both food waste and water consumption and increase efficiency at the same time.

Marcelissen food processing machines are the next step in efficiency, automation, waste reduction and high quality products.

Co-creation is our key to success

Perfect chips demand precision. Marcelissen’s advanced food processing machinery ensures optimal peel, cut, and quality — helping you meet rising consumer expectations while reducing waste and operational costs. Let’s shape the future of chips together.

At Marcelissen, we believe that precision goes beyond engineering. It starts with co-creation. As one of the core pillars of our business, co-creation means working side-by-side with our clients to truly understand their processes, challenges, and ambitions. We don’t just deliver machines, we deliver solutions tailored to your exact needs. From potato variety to end-product requirements, every detail matters. That’s why we invest time in on-site visits, open dialogue and iterative design processes that fine-tune our technology to your production line.

The result? Consistently high-quality chips, less food waste, lower water consumption and greater yield. This hands-on, collaborative approach ensures that our machines integrate seamlessly into your workflow and meet the strictest industry standards for hygiene and efficiency. Together, we develop not only state-of-the-art machinery, but long-term partnerships based on trust, transparency and shared innovation.

We can also assist with logistics to ensure your machine is delivered in the most efficient way possible.

With Marcelissen, you don’t just keep up with the market... you lead it.

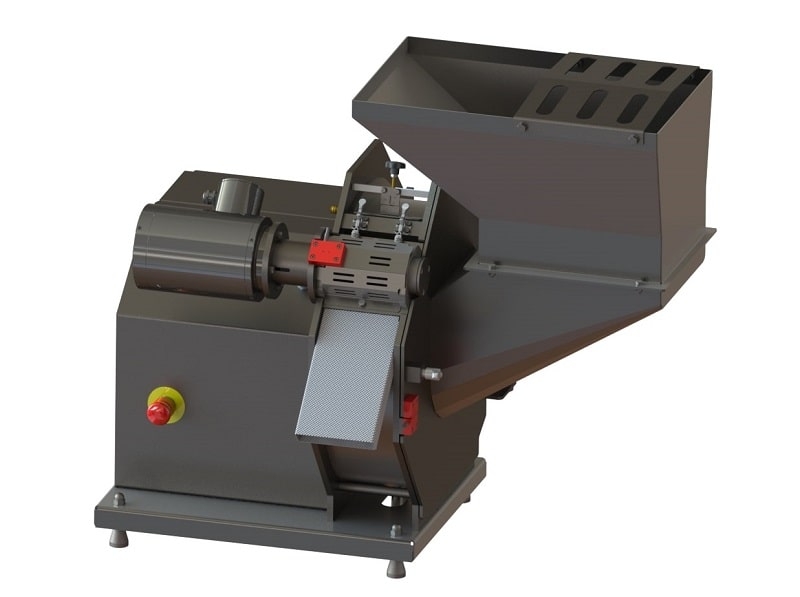

Slitmaster 105

Explore this machineCompact Hydro Cutter – SHC

Explore this machineDrum Roller Peeler – SKR

Explore this machineSliver Remover – SR2

Explore this machineOur recent cases

Farma Pour

Farma Pour s.r.o., a small-scale, warm-hearted potato processor in the Czech Republic, is a fine example of a company with strong local roots and ambitious growth plans. In addition to selling high-quality potato products, they run a charming farm shop where they also offer their own dairy products, such as cheese and yogurt, to the local community.

Vätternpotatis AB

Vätternpotatis AB, located on the shores of the enchanting Lake Vättern, is the proud source of the beloved Vättern potatoes. The fertile fields near this Swedish lake provide the perfect environment for growing potatoes. Cultivation is managed by carefully selected, IP-certified growers who supply the exceptional potatoes that eventually find their way into modern kitchens, where they are processed into high-quality products.

Bring more efficiency to your food processing.

Ask us how.