Reno LLC

2024

Customer at Marcelissen

6

Delivered machines

Interested?

Contact us!

2024

Customer at Marcelissen

6

Delivered machines

Interested?

Contact us!

A new start for Reno LLC

Reno LLC is a potato processing company rooted in the outskirts of Kyiv, Ukraine. After a turbulent period, their factory needed to be rebuilt to restart production. With resilience and determination they have made a fresh start. During this process they searched for a new processing line for their potatoes. Thanks to support from the DHI subsidy provided by the Netherlands Enterprise Agency, we were able to supply Reno LLC with a demonstration model of our peeling line with water transport.

The problem

When the factory suffered severe damage, Reno LLC faced a major challenge. After a period of stagnation and uncertainty, it quickly became clear that entirely new machines were needed to get production back on track. The obstacles were significant, but they did not shy away from them.

While searching for a solution to relaunch their potato processing operations, owner Sergey Zavgorodniuk came into contact with Marcelissen. He was looking for a reliable Western European processing line to restart production as quickly as possible. Marcelissen had the right technology to breathe new life into the company.

The solution

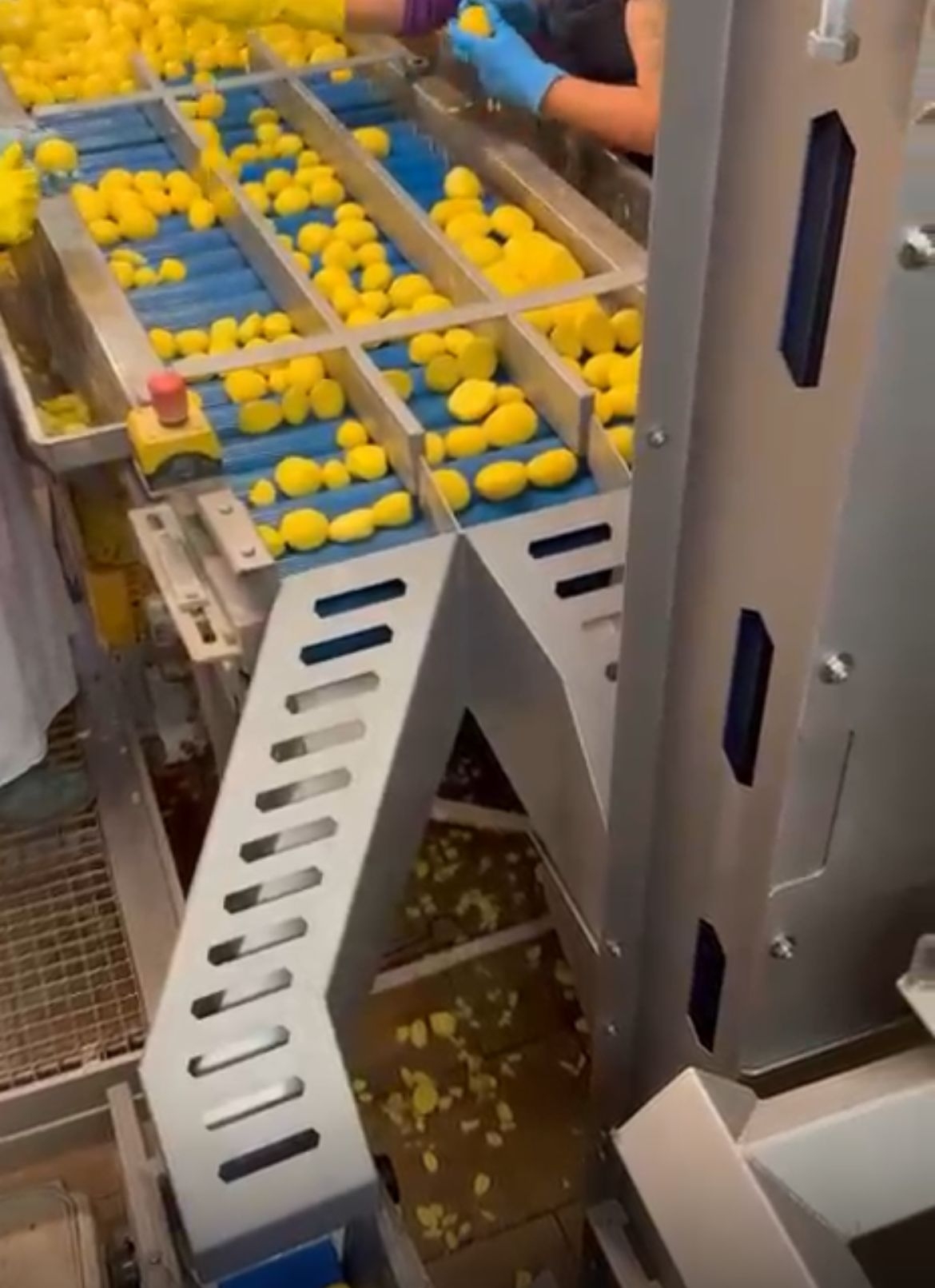

The key to success lay in brand-new machines from Marcelissen. A peeling line with water transport was an entirely new setup, one that had never been installed at a customer’s site before. With a capacity of no less than 3.000 kg, this machine is a major upgrade compared to Reno LLC’s previous equipment. Alongside the peeling line, several other machines were installed in Ukraine:

Drum Knife Peeler: A global standard for peeling and re-peeling of potatoes and other root vegetables.

Transport Auger: Ideal for controlled transport of potatoes and other root vegetables.

Auger Destoner: Essential for removing sand and stones from the production flow.

Wet Hopper with Outfeed Conveyor Belt: Designed for receiving and buffering (un)peeled products under water, consisting of a storage bunker with a discharge belt to serve as a buffer in the production line.

Inspection Belt: A flat conveyor belt for inspecting and sorting processed or cut end products.

Electronical Weigher with Wet Hopper: This automatic weighing machine is equipped with an electronic weighing system. Weight settings and other parameters can be adjusted via a touchscreen. Once the preset weight is reached, the supply chain stops and the weigher is ready to release the batch into a bag or container.

Installing the machines required thorough preparation. Under the supervision of our Technical Director Sjoerd Treuen, the Reno LLC team successfully installed the line. Maintenance for these machines is carried out remotely. From our location in Venlo, we monitor the machines’ status and provide Reno LLC with guidance on resolving any issues in the best possible way. This significantly reduces travel time while allowing Reno LLC’s technical team to handle maintenance independently.

The result

The peeling line enables Reno LLC to run its potato production in Kyiv at full capacity. Ukraine is the largest potato producer in Europe, making Marcelissen’s machines a perfect fit for the specific needs of the local market. Not only do they offer a solution for current challenges, but they also lay the foundation for future growth.

Although the company has ambitions to expand internationally in the future, its current focus remains on strengthening its position in the domestic market. This investment is a crucial step in restoring and expanding their production capacity, allowing them to meet the rising demand within Ukraine.

Sergey Zavgorodniuk is highly satisfied with the outcome of this project and the performance of the machines:

“Thank you so much for the machines and guidance throughout the project. The machines look great but also the ease of use of the control panel’s interface is outstanding. The first production hours were successful and I am convinced this will continue!”

The impact

The impact of this peeling line is, quite naturally, immense. It not only provides Reno LLC with an impressive increase in production capacity but also enables the company to explore new manufacturing possibilities. Processing potatoes on such a large scale is highly unique in this region and represents an invaluable asset.

Moreover, the facility serves as a demonstration site for other potato processors in Ukraine. Companies from the region visit to view the advanced production line and experience its full range of capabilities. This openness not only creates opportunities for Reno LLC to share its expertise but also inspires other players in the market. In this way, the factory functions as a hub of development within the Ukrainian potato industry, exemplifying the solidarity of a nation in challenging times.

Meer klantcases

Farma Pour

Farma Pour s.r.o., a small-scale, warm-hearted potato processor in the Czech Republic, is a fine example of a company with strong local roots and ambitious growth plans. In addition to selling high-quality potato products, they run a charming farm shop where they also offer their own dairy products, such as cheese and yogurt, to the local community.

Vätternpotatis AB

Vätternpotatis AB, located on the shores of the enchanting Lake Vättern, is the proud source of the beloved Vättern potatoes. The fertile fields near this Swedish lake provide the perfect environment for growing potatoes. Cultivation is managed by carefully selected, IP-certified growers who supply the exceptional potatoes that eventually find their way into modern kitchens, where they are processed into high-quality products.