Rol-Nas

2024

Client at Marcelissen

5

Machines delivered

Interested?

Get in touch with us

2024

Client at Marcelissen

5

Machines delivered

Interested?

Get in touch with us

The solution for more efficient potato processing

Rol-Nas Sp. z.o.o. is a family-owned company that has played a crucial role in the Polish potato processing industry for many years. Specializing in processing potatoes for the local market, the company always prioritizes quality and efficiency. As part of their ongoing commitment to innovation and sustainability, Rol-Nas decided to modernize their production process by integrating new, advanced food processing machinery.

The problem

Like many companies in the food industry, Rol-Nas faced the challenge of meeting the growing demand for their products. Their existing peeling line was outdated and no longer met the required capacity or efficiency. The older machines not only had limited capacity but were also less sustainable and reliable, leading to frequent downtime, higher operational costs, and an increased risk of production loss. Additionally, the old technology was no longer capable of delivering the consistency and quality needed to remain competitive in the modern market.

The solution

To address these issues, Rol-Nas decided to implement a new production line, with an advanced peeling and scraping section as well as precise inspection, both being critical components. After extensive research and visits to various Western European machine builders, Rol-Nas ultimately chose the expertise and solutions provided by Marcelissen.

The following machines were delivered to optimize peeling, scraping, and inspection within their current production line:

Drum Roller Peeler SKR28/3000: This machine efficiently removes the potato skins while maintaining their round shape.

Wet Hopper with Outfeed Gooseneck Conveyor BNTZ350/400: This system ensures a smooth, accurately dosed transition between processing steps for continuous throughput.

Drum Knife Peeler SMT1000/3000: The knife peeler achieves an aesthetically pleasing result, extending shelf life and preserving the potatoes’ round shape due to the drum and dosed feeding system.

Wet Hopper with Outfeed Gooseneck Conveyor BNTZ350/400: Used again to provide a smooth transition and rinse off any remaining skin residue.

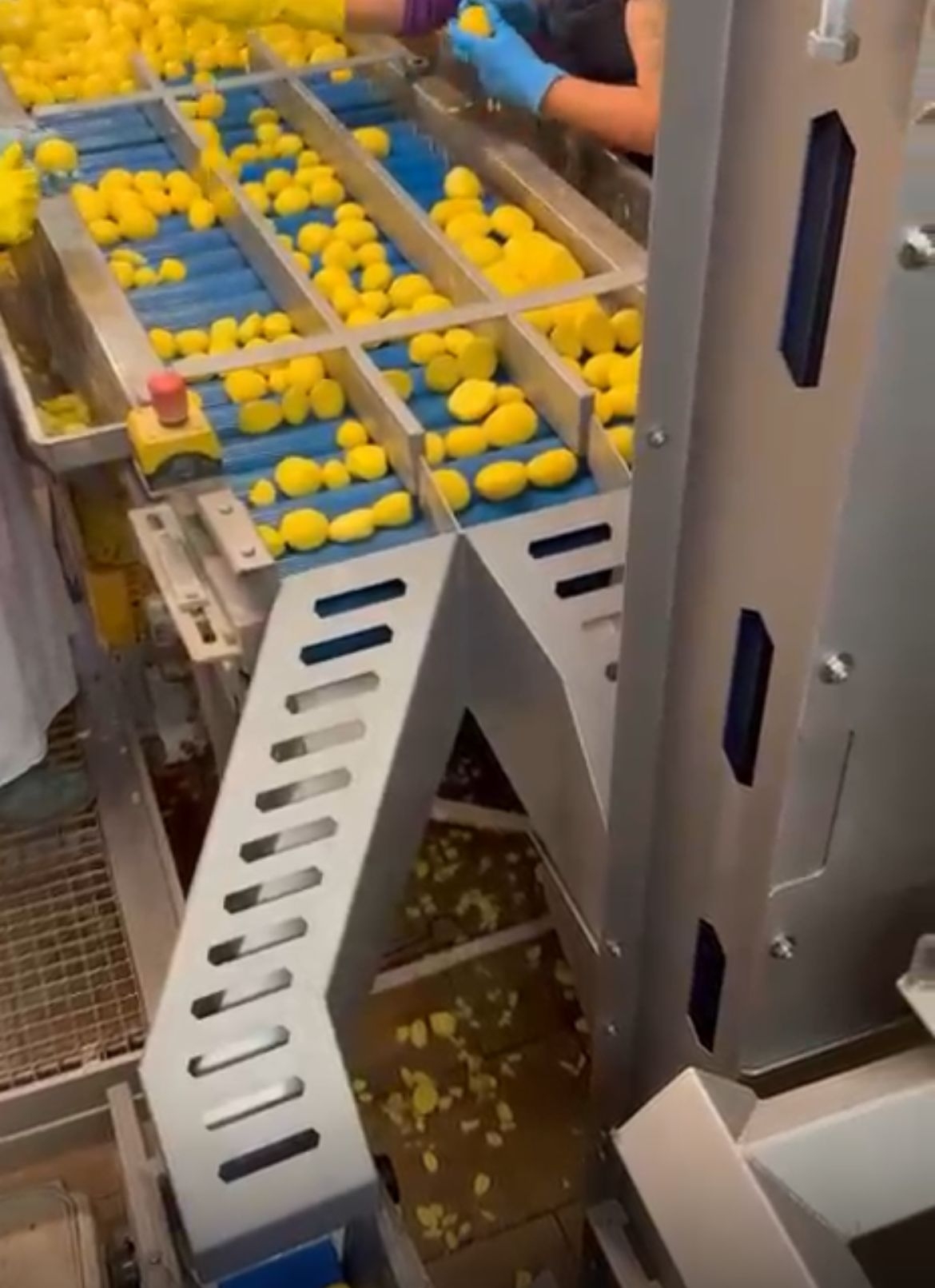

Roller Inspection Belt IR800/4000: The rotating profiled rollers cause the potatoes to turn, allowing staff to inspect them thoroughly and remove any remaining irregularities before further processing.

The combination of standard configurations and custom solutions ensures that the new line seamlessly integrates with the existing infrastructure at Rol-Nas. During the implementation of the new production line, special attention was paid to the waste system, a critical aspect for keeping the production hall clean and hygienic. The waste is collected beneath the production line, gathering the skins and other by-products, which are then pumped out of the hall directly. This prevents waste buildup in the workspace and contributes to a cleaner working environment. Additionally, the control cabinet was designed with hygienic features, preventing dirt accumulation.

Moreover, the production line offers remote monitoring of essential process information through an HMI (Human Machine Interface) system. This enables quick responses to issues and allows for remote support. For instance, thermal protections of motors can be monitored to prevent overheating, an integral part of predictive maintenance that helps identify issues early and minimizes downtime. The line is automated with different programs tailored to the type of potatoes and the desired peeling process. Operators can manage specific settings with their individual login, while the system is designed so that staff only access essential information.

Technical Director Sjoerd Treuen personally oversaw the operational release and final check, ensuring proper alignment of settings and speeds during the startup phase. This hands-on approach ensures not only a smooth launch of the production line but also strengthens the relationship with Rol-Nas.

The result

Following the installation of the new machines, Rol-Nas' production capacity significantly increased. The old, smaller peeling line simply couldn’t compete with the efficiency and speed of the new setup. With the Drum Roller Peeling Machine and the Drum Knife Peeler, Rol-Nas can now process larger quantities of potatoes in less time, all while maintaining consistently high product quality. This is crucial for meeting market demand while controlling production costs.

In addition, the integration of the Water Buffer with Gooseneck Conveyor Belts and the Roller Inspection Belt has resulted in a smoother, more efficient production process. Transitions between the various processing phases are now seamless, reducing the risk of downtime and increasing throughput.

The impact

The increased efficiency has improved Rol-Nas' market position and reduced operational costs, enhancing the company’s profitability.

Furthermore, the sustainable technologies provided by Marcelissen have enabled Rol-Nas to reduce their ecological footprint. By using less energy and water during the production process, Rol-Nas is contributing to a more sustainable food industry, which is becoming increasingly important in a world focused on eco-friendly production methods.

Lastly, the collaboration with Marcelissen has not only led to technological advancements but also to a new and valuable partnership between the two companies. The trust Rol-Nas placed in Marcelissen is further evidence of the quality of our machines and the expertise of our team. This collaboration has not only helped Rol-Nas overcome their current challenges but also positioned them for future growth and developments in the potato processing industry.

More client cases

Farma Pour

Farma Pour s.r.o., a small-scale, warm-hearted potato processor in the Czech Republic, is a fine example of a company with strong local roots and ambitious growth plans. In addition to selling high-quality potato products, they run a charming farm shop where they also offer their own dairy products, such as cheese and yogurt, to the local community.

Vätternpotatis AB

Vätternpotatis AB, located on the shores of the enchanting Lake Vättern, is the proud source of the beloved Vättern potatoes. The fertile fields near this Swedish lake provide the perfect environment for growing potatoes. Cultivation is managed by carefully selected, IP-certified growers who supply the exceptional potatoes that eventually find their way into modern kitchens, where they are processed into high-quality products.