Börde Vita GmbH

2019

Client at Marcelissen

700

Hectares cultivation area

60

Metric tons to process every day

Interested?

Get in touch with us

2019

Client at Marcelissen

700

Hectares cultivation area

60

Metric tons to process every day

Interested?

Get in touch with us

Automating the sorting process

Börde Vita GmbH is a potato peeling company located in the heart of Magdeburg Börde, a region in Saxony-Anhalt in the eastern part of Germany, specializing in the processing and refinement of Börde consumption potatoes, which are 100% produced by Tonkens Agrar AG.

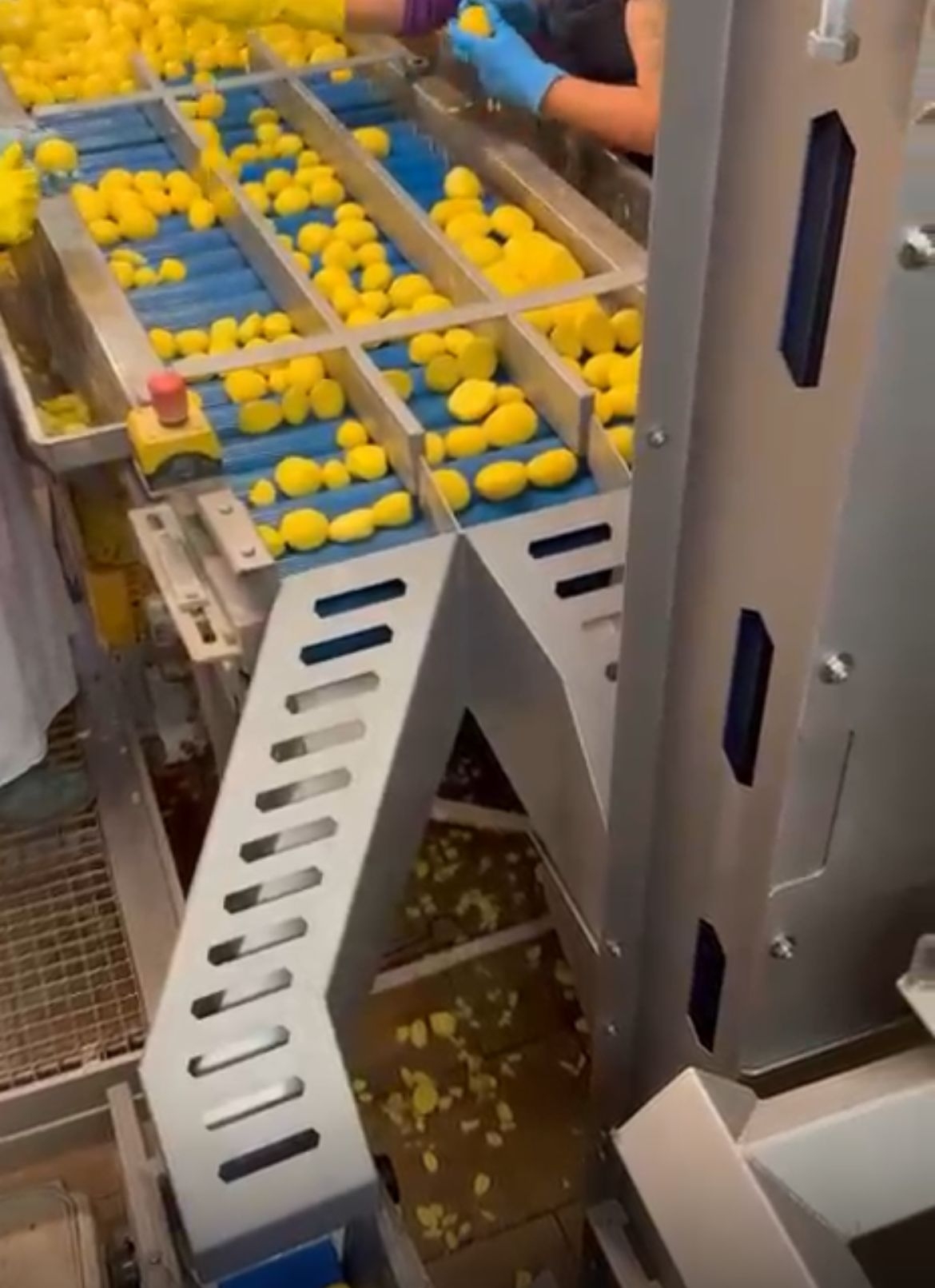

They produce up to 60 tons of all common cutting forms daily, such as whole, halved, diced, sliced, or pom-pom.

Tonkens Agrar AG is a grower in the Magdeburger Börde, cultivating potatoes for its own peeling company, Börde Vita GmbH, on an area of approximately 700 hectares, with an average yield of 50 tons. Additionally, they cultivate onions on about 70 hectares, which are also processed into slices, cubes, and whole peeled onions at Börde Vita.

Established in 2012 700 hectares of cultivation area 60 tons to process per day.

The problem

The company was using optical sorting machines that still required a significant amount of post-sorting work. Given the volumes processed by Börde Vita on a daily basis, this was a highly labor-intensive process. The management was dissatisfied with this situation and wanted to deploy the workforce more efficiently.

During a trade fair in 2022, we connected with Börde Vita GmbH and were able to suggest a suitable solution.

The solution

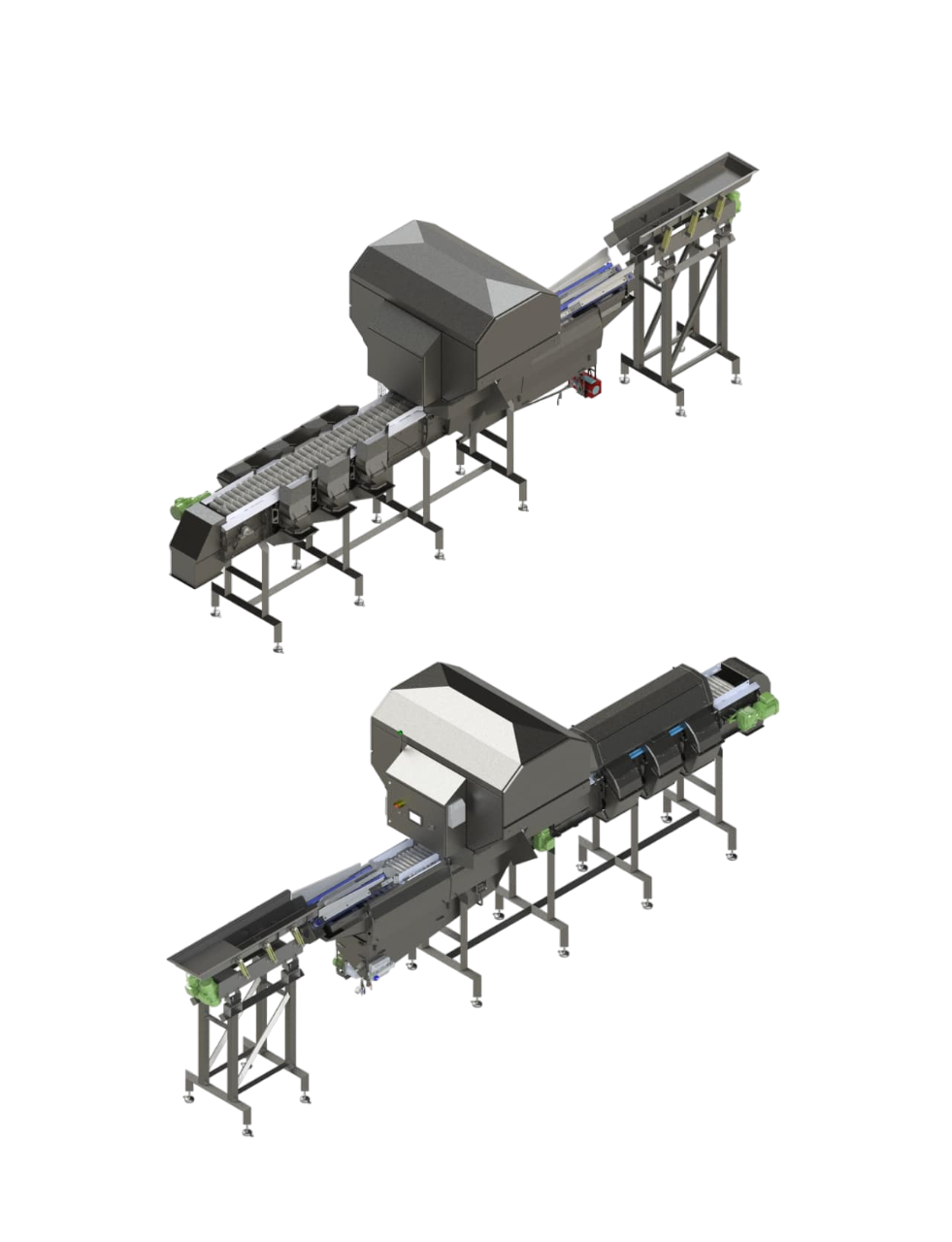

The Optical Sorting Machine Pneumatic is specially designed for optically reading scraped, peeled, and even unpeeled potatoes for defects, color, size, shape, and waste.

After visiting Marcelissen in Venlo, they were immediately impressed with our innovative machine and convinced of its possibilities and applications within the process of Börde Vita GmbH.

However, the management wanted to test the machine on-site for a week to ensure that it could deliver the expected capacity and quality fully automatically. After a week of testing in production, the decision was quickly made: the machine was purchased and never returned to Belfeld.

To ensure continuity, Börde Vita decided to purchase a second machine.

The result

The two Optical Sorters now work in conjunction with the old machines, where the old machines handle the pre-sorting work, and Marcelissen’s sorters handle the qualitative and bulk work. This combination has significantly increased the capacity of Börde Vita GmbH, greatly benefiting the company’s growth.

Moreover, the employees previously involved in manual sorting can now be deployed elsewhere in the process, resulting in cost and efficiency benefits.

Börde Vita GmbH is highly satisfied with our sorter’s performance, product quality, and collaboration with Marcelissen. A contract has also been signed to have our Marcelissen technicians visit the location four times a year to perform preventive maintenance.

The impact

The current setup of pre-sorters and Marcelissen’s optical sorters has had a significant impact. Firstly, there is no longer a need to employ additional personnel during sorting. Secondly, the product quality has improved due to the extremely precise sorting. Lastly, the data obtained from the optical sorting machines allows them to measure potato quality and take necessary actions to further improve it.

More client cases

Farma Pour

Farma Pour s.r.o., a small-scale, warm-hearted potato processor in the Czech Republic, is a fine example of a company with strong local roots and ambitious growth plans. In addition to selling high-quality potato products, they run a charming farm shop where they also offer their own dairy products, such as cheese and yogurt, to the local community.

Vätternpotatis AB

Vätternpotatis AB, located on the shores of the enchanting Lake Vättern, is the proud source of the beloved Vättern potatoes. The fertile fields near this Swedish lake provide the perfect environment for growing potatoes. Cultivation is managed by carefully selected, IP-certified growers who supply the exceptional potatoes that eventually find their way into modern kitchens, where they are processed into high-quality products.