Industrial Potato Peeler

An Industrial potato peeler is of great importance when processing potatoes into a final product, such as sticks and slices. Marcelissen has several machines for peeling potatoes at a high pace, ideal for businesses in the food processing industry.

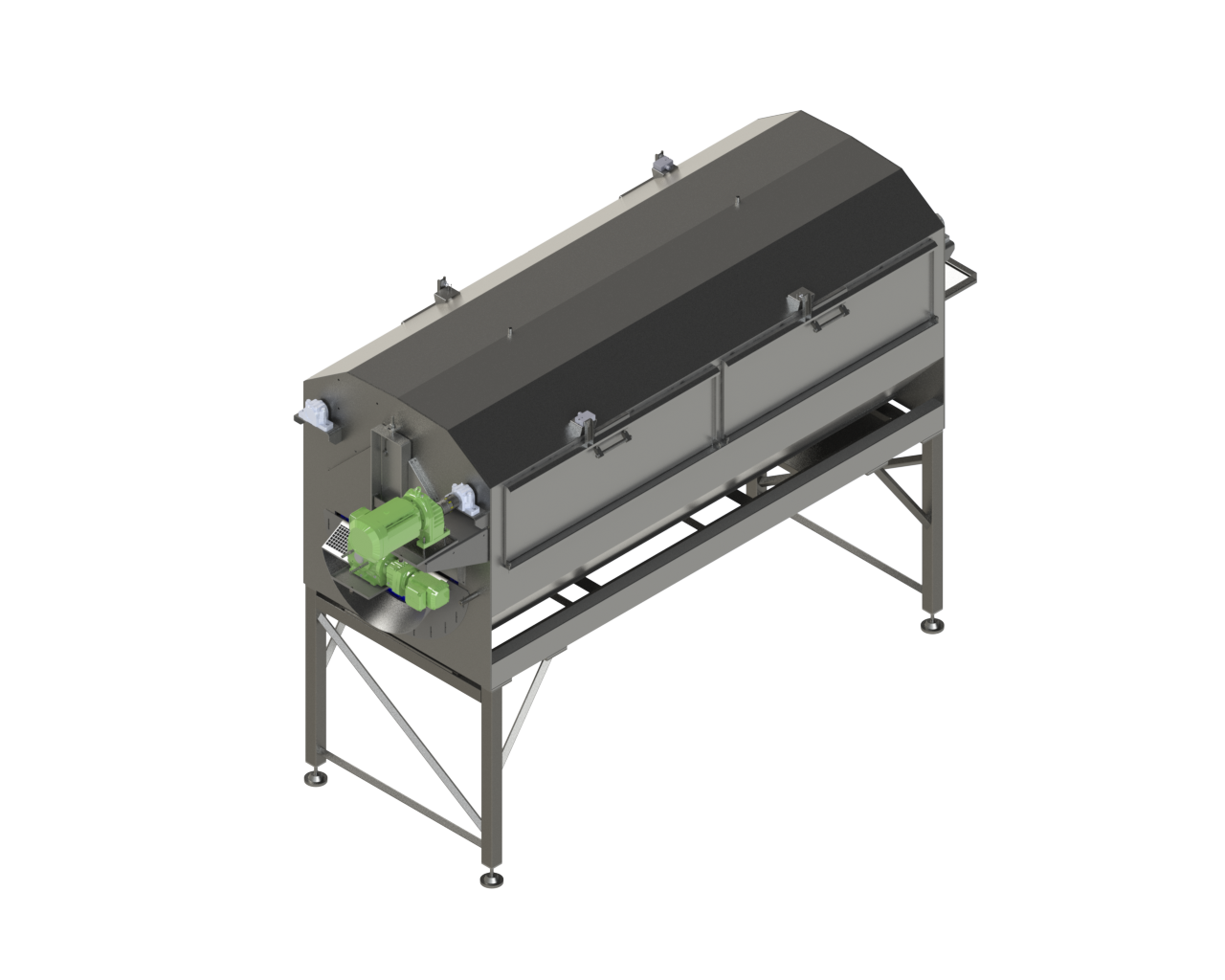

Drum knife peeler – SMT

The Drum Knife Peeler – SMT is an industrial potato peeler consisting of three main components,namely a frame with a stable knife drum and auger. The potatoes are peeled by the knives while being transported by the auger.

The knives are held firmly in place by AISI 304 stainless steel beams. This prevents the knives from breaking. Additionally, the beams can easily be removed or replaced. The knives are placed in such a way that the efficiency and capacity are increased considerably. They can also be replaced quite easily, which leads to a much lower downtime. Normally downtime takes more than a day, because every knife beam has to be taken out separately. Whereas downtime on the Marcelissen Knife Peeler can be done in a matter of hours. The lifetime of the machine has also been extended by using stainless steel for the bearings and bearing houses.

Other advantages include:

Suitable for repeeling steam peeled potatoes.

During the peeling process, it is not necessary to use water.

A special construction ensures 100% peeling, because the potatoes will be optimally rotated.

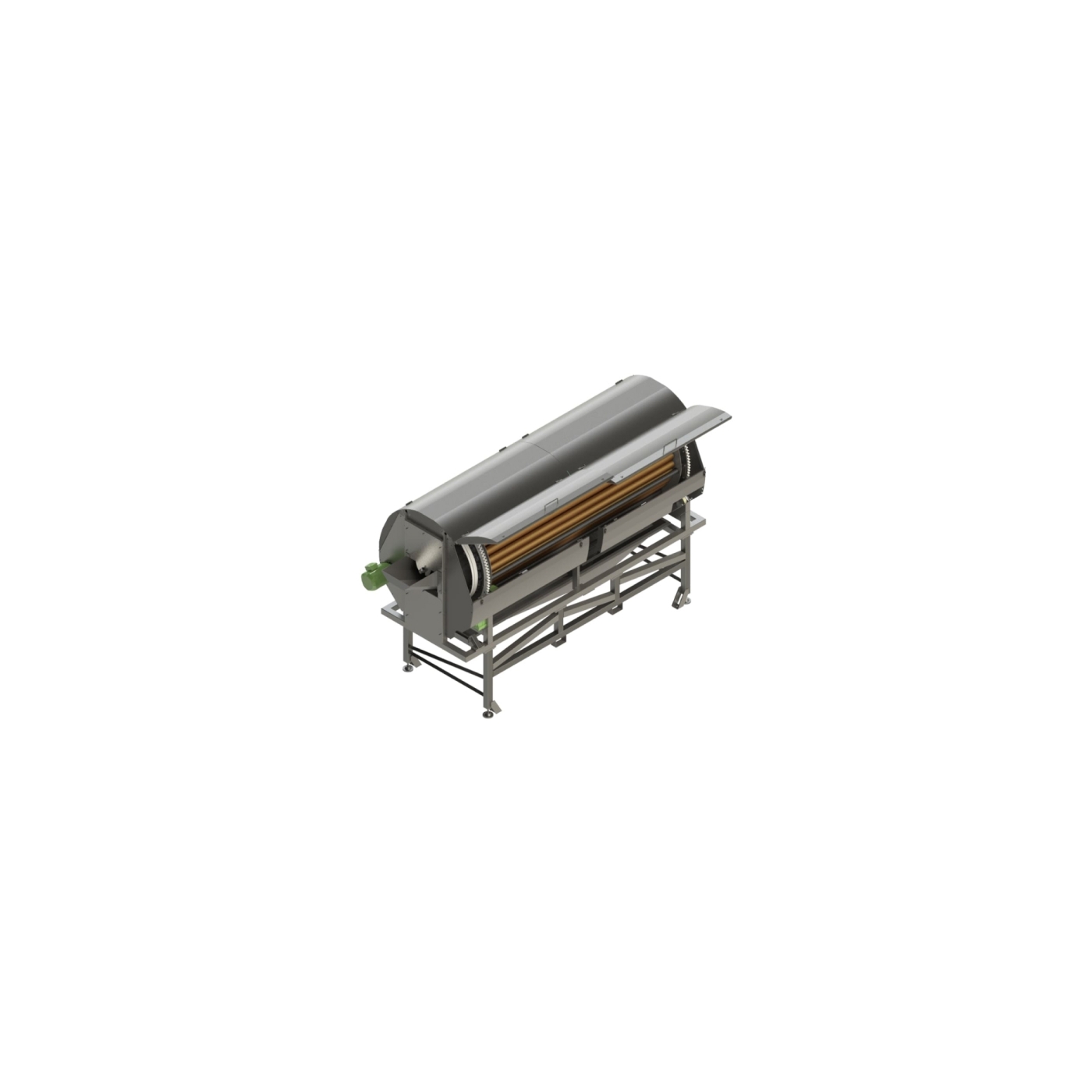

Drum Roller Peeler – SKR

Unlike the SMT, the SKR is a roller peeler that uses abrasive rollers constructed in a drum (instead of knives) to remove the skin from potatoes. The potatoes are being peeled carefully but thoroughly, because the machine moves at a low speed.

In order to obtain the best result with this industrial potato peeler, a constant supply of potatoes and a proper dosing is needed. An auger transports the product to the discharge. When needed, the drives, rollers and auger can be changed by using frequency converters. Waste is discharged underneath the machine, into the water. However, it can be used without water as well.

Throughout the years we have found ways to improve the SKR. Some important changes have been made to the construction of this industrial potato peeler.

Changing the rollers can be done within a few minutes

Increase of product capacity

Noise has been reduced considerably

Batch Peeler - SKB

The Batch Peeler - SKB is another industrial potato peeler out of the assortment of Marcelissen. This machine differs from the previous two models, because it uses an abrasive peeling disc on the potatoes and is a more compact machine. It’s important that the machine receives a constant supply of potatoes in order to obtain a high quality of peeled products.

Using timers, the filling, peeling and discharge time can be adjusted as needed. Just like the Drum Roller Peeler – SKR, the waste is removed underneath the machine. This can be done with or without water.

It’s important to know that the SKB900 batch peeler is specifically designed for the manufacturers of potato chips.

Interested in one of our industrial potato peelers?

Marcelissen is happy to provide you further information on our industrial potato peelers. Feel free to ask us anything concerning the specifications, functioning and pricing of our machines. Fill in the contact form to reach out to us. You can include a question if you want to.

At Marcelissen, we specialize in providing high-end machines for the food processing industry. Therefore, we might have other machines that are interesting for you. Click here to see our overview of machines for the B2B market.

Customisation and innovation start here.

Give us a call or fill out our contact form and we’ll call you. We love to discuss your current and future challenges and needs. Curious for a quote, information about a machine or a solution we can provide? Contact us today!

Contact form

Fill out our contact form and our team will reach out to you as soon as possible!

Contact information headquarters