A potato sorting machine, a true must-have

A potato sorting machine has become a must for food processing companies that process potatoes. This is a link that is particularly significant in the field of quality control. As a result of rapid developments, there are many variants of grading machines for potatoes. At Marcelissen we have different types, each with its own unique characteristics.

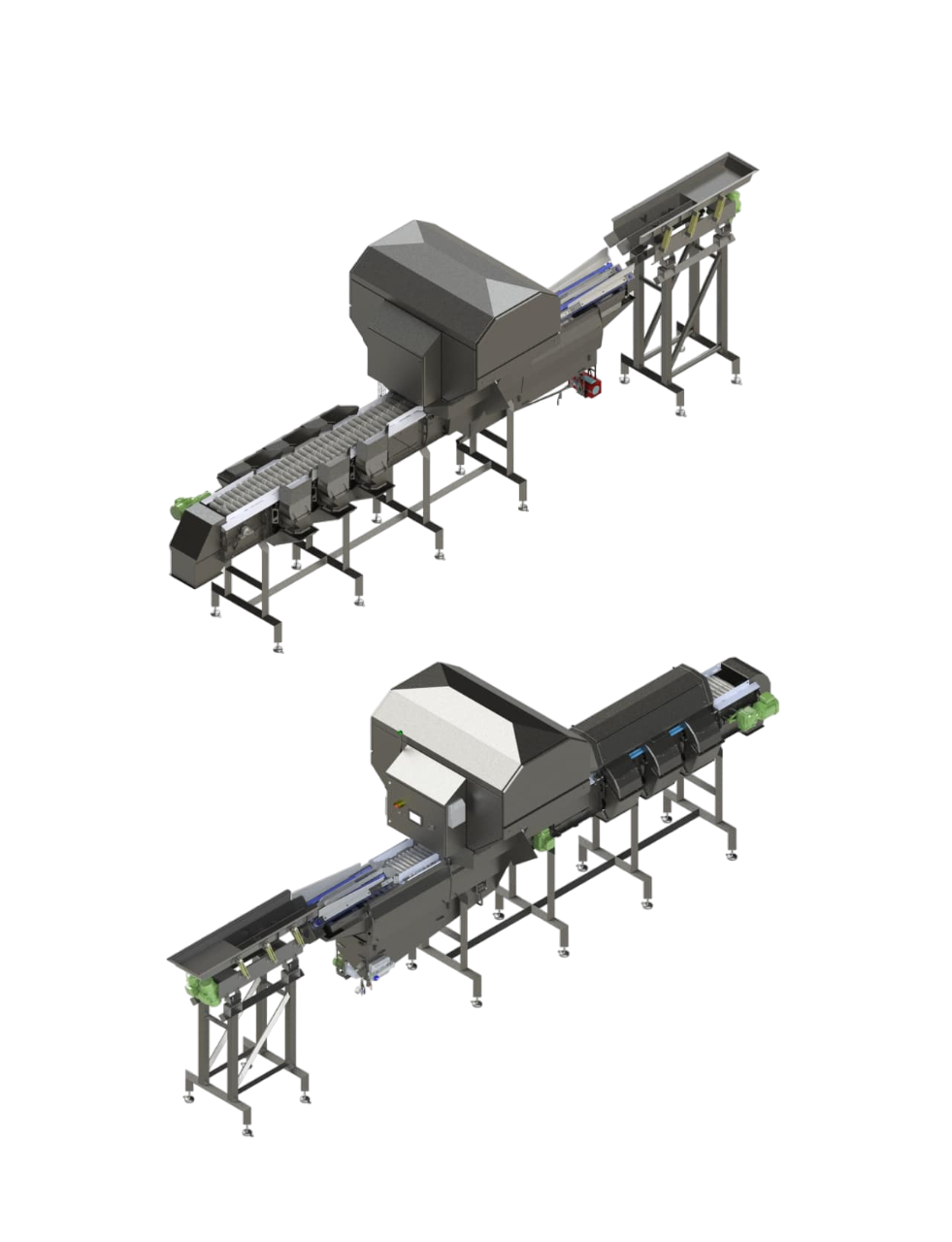

Optical Sorter – SO (L) of (M)

Marcelissen’s optical grader sorts the potatoes according to various characteristics, namely size, colour, number of defects and size of the defects.

First of all, the potatoes are transported to the sorting room one by one on two separate rolls. Within this space, scans are made of the potatoes, in which factors such as quality, characteristics and possible defects are discussed. Incidentally, each potato is scanned 360 degrees. A potato rotates several times when it is under the camera on the roll transport. All important details are measured in this way.

After the data from the potatoes has been collected, the optical sorter proceeds to the sorting work. This is done by means of ‘blow nozzles’ or ‘sliders’. These are pre-set on the basis of the previously obtained information, consisting of issues such as quality and specific characteristics. This way of sorting works very fast and is also very accurate.

Short Piece Sorter – SV

Besides the sorting of whole potatoes by means of an Optical Sorter, smaller pieces also need to be sorted out from the product flow. The Short Piece Sorter is the ideal solution for companies who are looking for a more straightforward sorting machine.

This model is perfect for sorting out unuseable, small pieces of potato that do not form the end product for the customer. This machine can also be used for dosing the products. In addition, a combination of both processes can be achieved. The capacity is 8.000 kg/hour. In the video below you can see a demonstration of this machine from Marcelissen.

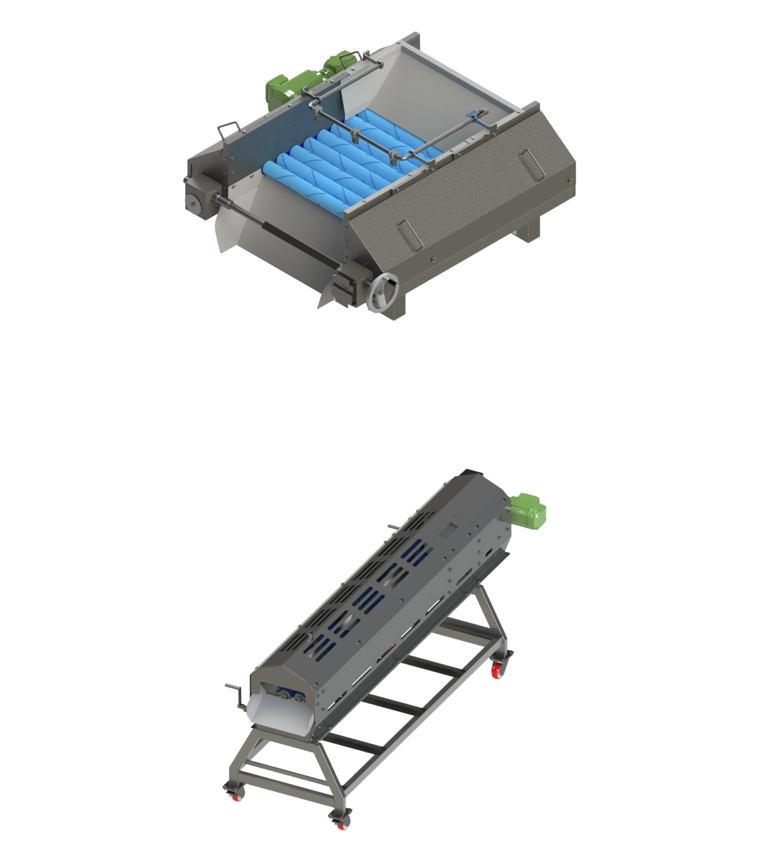

Potato Diameter Sorter - SRL

Larger than the Short Piece Sorter, is the Potato Diameter Sorter. With this grader, potatoes (and other tuber vegetables such as beets) can be sorted on diameter. The rollers are placed in a V-profile and the unique composition of the machine ensures that the rollers can be infinitely adjusted at the bottom.

Since this machine is placed at a slight angle in combination with the driven rollers, the actual sorting will take place. Even though the sorting sizes have to be predetermined, the sorting opening can be slightly adjusted, so that some flexibility in diameter sorting is possible. Based on the number of plastic rollers (two or more) the capacity can be estimated, which can vary up to 20.000 kg/hour. The Potato Diameter Sorter can act as a link within a potato processing line, although this is not necessary and the machine is often used ‘stand-alone’.

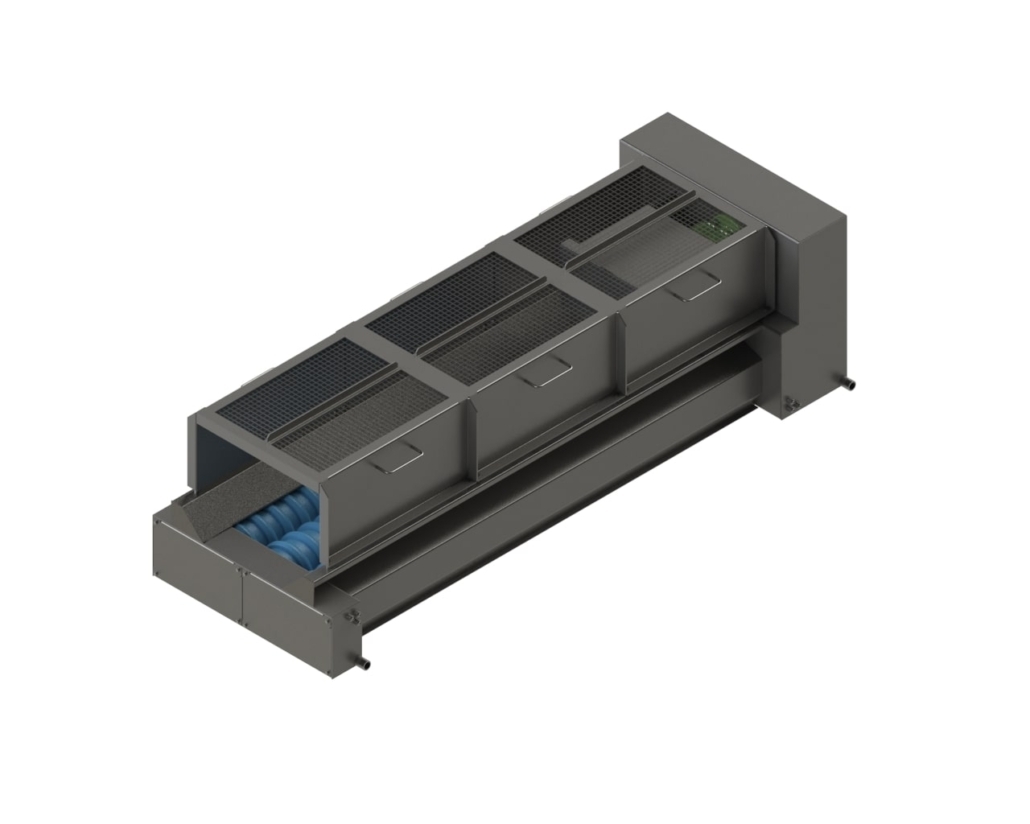

Sliver Remover (roller sorter)

After cutting fresh fries, cubes or slices, there are inevitably short and thin pieces in the product stream, after all potatoes are not squared or rectangular. In order to realise a high quality end product, these short and narrow pieces have to be sorted out. We do this by means of our Sliver Removers.

This machine is specially constructed to separate too small product particles and/or waste from sliced and whole products. The main advantage of this sorter is that the roll opening during the production process can be easily, quickly and precisely adjusted from 3 to 23 mm or 4 to 24 mm.

The new generation Sliver Removers are very easy to maintain. The rollers can be adjusted during the production process and no water is needed for cooling and lubricating the bearings. When processing potato products, there is always the possibility to add a spray tube with which the released starch can be rinsed away.

All rollers have the same rotation direction and are equipped with spirals. This creates a good product distribution, which is very important in achieving a good sorting quality. The product to be sorted moves across the rollers with the direction of rotation of the rollers, whereby breakage is excluded.

The waste can be disposed of underneath the machine. A spray tube is mounted above the rollers for the removal of any sticking parts.

The roll opening of Sliver Removers can be adjusted up to a maximum opening of 20 mm between the rollers. Furthermore, nowadays we have a split-sizer where on one machine two halves can be adjusted separately, this gives 3 sorting possibilities.

The plastic rollers are available in cream and blue and always come with an FDA certificate. Optionally, the Sliver Removers can also be equipped with stainless steel rollers.

Capacity: up to 20.000 Kg/hour

Interested? Please contact us

Marcelissen has various options for potato sorting and grading machines. They all differ from each other in terms of functions. For example, the Optical Sorter sorts the potatoes itself, distinguishing between the quality, purpose and sizes of the potatoes. The Short Piece Sorter, on the other hand, separates the potatoes from small pieces of product or skin that should not be further processed. For more information about our sorting machines or advice on a suitable solution for your situation, please leave your contact details. This can be done very easily. Fill in the contact form and we will contact you. Of course you can always take a look at our total range of food processing machines. To do so, click here.

Customisation and innovation start here.

Give us a call or fill out our contact form and we’ll call you. We love to discuss your current and future challenges and needs. Curious for a quote, information about a machine or a solution we can provide? Contact us today!

Contact form

Fill out our contact form and our team will reach out to you as soon as possible!

Contact information headquarters