Circular economy: what, how and most importantly why!

A world without waste, a place where organic substances, food and nutrition are used optimally and leftovers are reduced to the absolute minimum. Who wouldn’t want to contribute to that with their business? Now that we have concluded that you want to reduce your waste it occurs to you that this is easier said than done, because where should you start? The principles of circular economy are a good start. You can read all about it in the blog below!

What is a circular economy?

A circular economy is an economic model/system consisting of closed cycles. In it, raw materials, products and components lose as little value as possible. Renewable energy is also used and system thinking is the central idea. Within a circular economy, an important pillar is to reduce the use of raw materials. Here, the use of raw materials must be reduced to as minimal a level as possible. Recycling is a second important pillar. In this process, raw materials must be reused in a high-quality manner. Also, products and components must be recycled to the maximum extent possible.

In a fully circular economy, there is no waste. This is because in a fully circular economy every residual stream is used to make a new product. This creates closed loops because producers take back and recycle their products after use. Another advantage of a circular economy is that the circular economic system is powered by renewable energy.

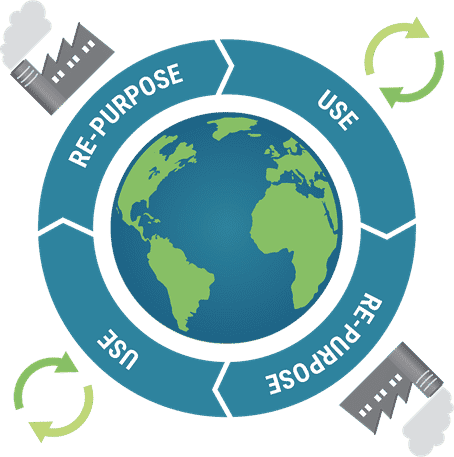

An example of this is capturing low-grade energy such as heat when using high-grade energy such as electricity. Another important part of a circular economy is system thinking. System thinking takes into account the short and long term consequences of choices that need to be made. It also includes the impact of the entire value chain. The picture below shows the process of a circular economy.

What are the benefits of a circular economy?

A circular economy has several benefits. For example, the global economy could benefit $2 trillion per year from more effective resource management. The main reason for this is that the cost of raw materials will decrease substantially. Another important benefit of a circular economy is the reduction of annual greenhouse gas emissions. Therefore, this benefit of a circular economy results in gains for the climate. These would arise from recycling, waste prevention and eco-design, among other things. Measures in this area can provide a net saving of €600 billion or 8%(+/-) of companies’ realized turnover in the EU. Also, a circular economy can be a stimulus for innovation of a company/region.

This is because it improves the competitive position. For example, a circular economy can ensure that producers can make their products of a higher quality. This allows consumers to use higher quality products. Another additional benefit of a circular economy is that the Netherlands could become less dependent on raw materials from abroad. This is because the raw materials used in a circular economy have a longer life span. A circular economy can therefore create a win-win situation.

‘’The global economy can benefit $2 trillion a year from the more effective resource management of a circular economy.’’

What can a circular economy bring to the Netherlands?

The transition to a circular economy also offers opportunities for the Netherlands. For example, the Netherlands can become less dependent on the import of rare raw materials and with a circular economy we can contribute to a cleaner environment. A cleaner environment enables ecosystems to recover better. Apart from the fact that environmental degradation affects plants and animals, it can also have a negative impact on us, humans. Think, for example, of the smog that can occur. A circular economy can ensure that CO2 emissions are reduced by approximately 10%. It would also be possible to save 20% water within industry. We benefit from this now and in the future. Besides a cleaner environment, there are also economic benefits/arguments for a circular economy. A circular economy generates as much as 7 billion euros and 50,000 jobs. This is a big number.

Marcelissen is located in the municipality of Venlo. How can we see around us, so in municipality Venlo, the applications of a circular economy already? In the principles of cradle to cradle, the applications of a circular economy can be seen. These are also applied in Venlo. Read more!

Cradle to Cradle in Venlo

Cradle to Cradle is the textbook example of sustainable entrepreneurship. It means that all raw materials used can be fully reused without losing their value. This means there is upcycling instead of downcycling. The municipality of Venlo is the first region in the world to apply the principles of cradle to cradle. An example of this is the city office (https://c2cvenlo.nl/) . The municipal office in Venlo has been built entirely on the principles of cradle to cradle. The products used in the construction of the council offices are designed in such a way that the raw materials can be reused. The municipal office in Venlo has the largest green wall in the world. Often the outdoor air in cities is poor due to the heavy traffic and buildings. One of the starting points for the construction of this municipal office was therefore to improve the outdoor air in Venlo. The plants used in the facade were specially chosen for the effect they have on the environment. As a result, the wall of the office functions as a kind of green lung. It filters fine dust. The facade consists of about 42,000 plants of about 40 different species. Together, the surface of the green facade amounts to over 2,000 m2. Other functions of the green facade are:

Air purification

Production of oxygen

Sound isolation

Isolate heat and cold

Water storage

Space for flora and fauna

The cradle to cradle principle can also be found at one of the local associations sponsored by Marcelissen, namely Scopias Atletiek. Located on Sportpark Vrijenbroek, the association became the first in the Netherlands to open a fully recycled athletics track in 2020. The plastic of the old track was ground into small balls, which were then reused as a carpet pad for the new track. In this way, the athletics club and its members are contributing to the transition to a circular economy.

What contributions should manufacturers of food processing machinery make to a circular economy?

Products from food processing machinery manufacturers must contribute to a circular economy. One example is circular design. In circular design, CE design should become a basic skill for individuals such as engineers. Manufacturers could also adopt circular business models. Here, a service model is one of the possibilities. Part of this is the take-back of machines. This leaves control of the machines with the producer. A consequence of this is that a possible disassembly, reuse or recycling becomes easier.

Within a circular system, material efficiency is a very important word. It is not based on cost, but on value retention. The focus here is on optimizing the product life cycle and closing the raw material chain. Manufacturers of food processing machinery can also make a trade-off when purchasing its stock. Here the consideration should be circular purchasing and/or procurement. This can extend the life of products.

‘’In circular design, CE design should become a basic skill for individuals such as engineers. Manufacturers could also adopt circular business models.’’

Why should the manufacturing industry be a circular industry?

The manufacturing industry is supposed to be a circular economy. There are also a number of reasons for this. One reason is to reduce the ecological footprint. The ecological footprint for a given year is a figure that represents the amount of biologically productive land and water surface that is required to maintain the consumption of a population group. This allows the population group in question to maintain its level of consumption and waste production. Reducing the ecological footprint is of great importance due to the increasing world population and increasing human consumption. This puts increasing pressure on the available raw materials and energy of our earth.

The manufacturing industry will also have an important role to play in the transition from a linear to a circular economy. This is because in a circular economy the prosperity and well-being of the population is increased. In a linear economy, there is unlimited use of various (polluting) raw materials. These are used in producing the products which are discarded after use. This is not a good model. The manufacturing industry can respond to the transition to a circular economy because they are often the developer, producer and supplier of many products and services that make this prosperity possible. See the illustration for the differences.

How is Marcelissen contributing to the transition from a linear economy to a circular economy?

Since a linear economy is a bad model, a solution must be created. The solution to this is a circular economy where products are reused and resources are used as efficiently as possible. But, how do we do this?

Marcelissen uses stainless steel in the production of machines. This type of steel can be reused for a very long time. In other words, not a linear product. Marcelissen also offers refurbished machines. This means that machines are reused and the lifespan of the machine is extended. Marcelissen’s machines also use less water. In the past, for example, the water used for scraping red beets was directly discharged. Nowadays, we have created a recirculation system that recirculates the used scraping water several times before it is finally disposed of. The recirculation system is shown in the figure below. The result is that fewer raw materials are used in production. As a result, Marcelissen ensures that customers can also contribute to the transition from a linear economy to a circular economy. For example, we ensure that certain parts remain available for a long time. This combined with good maintenance ensures that our customers’ machines can be kept in use for a very long time. For example, a customer of ours still had a scraper from 1970 in use until recently. In other words, this machine has been in use for more than 50 (!) years. This therefore brings us full circle. After all, everyone has to contribute to this transition.

‘’Marcelissen uses stainless steel in the production of machines. A customer of ours has a machine in use for more than 50 years.’’

Tips for applying a circular economy within the food processing industry

Currently, consumers are more environmentally conscious than ever before. Consumers are also becoming more careful in their food and beverage choices. As a result, food companies are expected to integrate increasingly sustainable practices throughout their supply chains. Currently, linear processes are still taking place in a number of places within our current economy. This is negative for our planet. In fact, true sustainability is not linear, but circular. A circular economy can be applied to every step within the food industry. When applied correctly, waste is reduced, the food industry becomes more efficient and value is added by/for a company. However, applying a circular economy within the food industry is not easy. Because of this, we have some tips for you on how to apply a circular economy within the food processing industry:

Invent new products. This will develop a new process, allowing a circular application to be applied from the beginning. For example, experiments are currently taking place with artificial proteins and food 3D printing. Take a look at the example of Loetje through this link.

Change production. This will allow production to fit into a sustainable model. The current production model being used has a major problem. That is waste. By changing production and making the production chains shorter, this can be (partially) solved.

Shorten the distribution. Dividing distribution into different streams makes distribution more efficient. An example of a division is an agricultural and an urban distribution.

Influence consumer choices. Producers are, of course, entirely responsible for creating a model that allows products to be recycled. However, by influencing a consumer’s behavior, product recycling can be encouraged. Also, a consumer can contribute to a circular economy by adjusting his/her diet. Indeed, food choices of a consumer can cause a shift in supply/demand.

Of course, we also want to continue to improve ourselves. This is because we currently find ourselves in a rapidly changing society characterized by volatility, uncertainty and complexity. As a result, we are always open to tips. So, do you have a tip for us that we haven’t mentioned, but that could be useful in the transition from a linear to a circular economy? Feel free to send us a message! We think it’s important and fun to learn from each other.