Industrial potato cutter

For food processing companies that focus on potatoes, an industrial potato cutter is a real must-have. At Marcelissen, we have a lot of machines for cutting potatoes that each have their own advantages. We’ll discuss some machines in depth. Don’t hesitate to contact us for further information. We are happy to help you!

Slitmaster 105

We have several machines that each have their own advantages. These cutters are suitable for food processing businesses, as well as the catering industry, like restaurants for example. We will provide you with interesting details on a number of french fries cutters of Marcelissen.

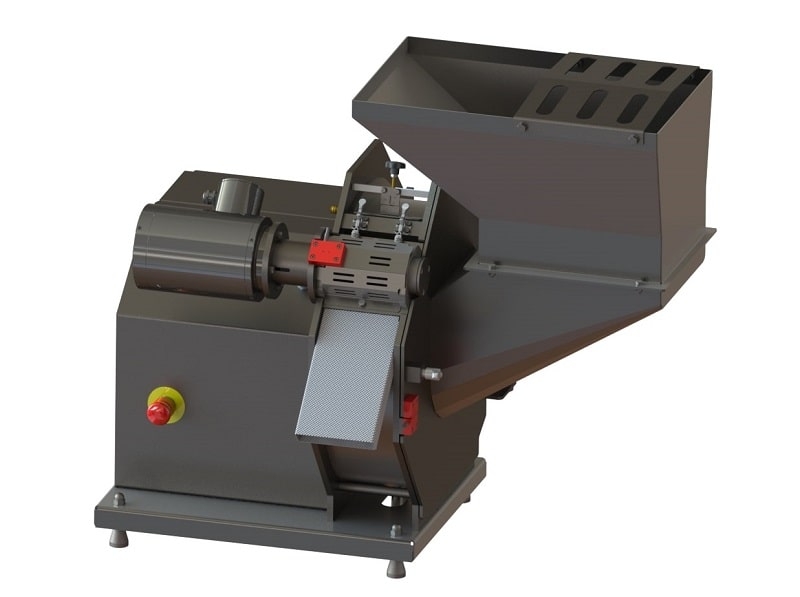

If you’re looking for a machine that can cut potatoes into fries, then the Slitmaster 105 might be your best solution. It’s quite small compared to our larger processing machines, so it can be used in kitchens of restaurants as well.

If you’re looking for a machine that can cut potatoes into fries, then the Slitmaster 105 might be your best solution. It’s quite small compared to our larger processing machines, so it can be used in kitchens of restaurants as well.

The Slitmaster 105 is capable of processing potatoes with a diameter of up to 105 mm, making it perfect for producing large French fry potatoes. Not only does this machine consistently cut the longest possible fries from each potato, minimizing waste and short fries, but it also features a quick-release system for effortless switching between cutting sizes, saving valuable time and minimizing downtime.

This cutter meets all CE safety regulations and is made of stainless steel. The speed of the cutting process can be adjusted by using the frequency converters.

1. Input potatoes.

2. Potatoes enter the rotor, which will be taken by the scoops.

3. Scoops take the potatoes and bring them to the ‘slice knife’, which creates potato slices.

4. These slices are finally cut into sticks by the ‘stick cutting knife’.

Because the Slitmaster 105 is relatively small, its capacity is lower than that of our larger machines. Therefore, it is perfect for use in kitchens and small processing companies.

Hydro Cutter - SH

At Marcelissen, we have several hydro cutters that each have their own advantages. We will discuss the different types of cutters in detail underneath.

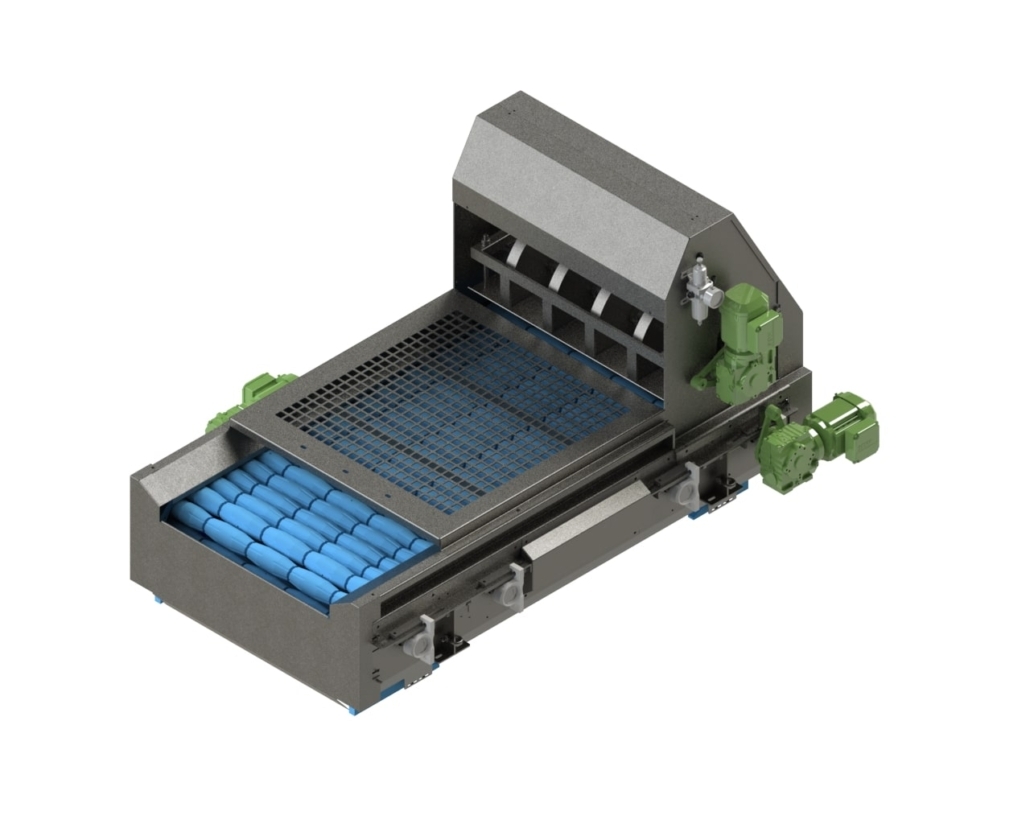

The Hydro Cutter is an industrial french fries cutter. It’s a lot bigger than the Slitmaster cutting machines and has therefore a much higher capacity (15.000 kg/hour compared to the 2.500 kg/hour of the Slitmaster). It is therefore ideal for the larger food processing companies. With this machine, the potatoes can be cut into chips, wedges and slices.

Because the Hydro cutter consists of several components, it’s possible to design the machine in such a way that it’ll fit in almost any production facility.

Hydro Cutter CSH

A newer, more compact version of the Hydro Cutter SH is the Hydro Cutter CSH. With its modest size of just 7.5 m2 , it is the most compact hydro cutter in the world. However, the components of the CSH are mostly the same when comparing it to the SH. It comprises a centrifugal pump, water tank, venturi tube, cutting section, discharge conveyor and decelerator.

The key advantages are:

A ‘quick release system’ makes it easy to change the knife and venturi (takes around 20 seconds).

Requires less adjusting and fine tuning.

It’s a standalone machine on wheels.

Capacity up to 6.000 kg/hr

Key advantages of the Marcelissen halving machine includes its ability to halve potatoes over multiple lanes, maximizing productivity and throughput. Additionally, the machine features a continuous cutting process and an integrated collection belt for seamless product handling and optional inspection, enhancing efficiency and quality control in potato processing operations. All our halving machines are custom-engineered and made. We work closely with you to ensure our machines meet your needs and are produced according to your specifications.

The continuous halving machine – DC is ideal for halving potatoes in two or more lanes. This halving machine consists of a unique infeed vibrator, aligning roller bed and cutting section. The potatoes are measured out carefully by the belt and are engineered in such a way that it creates a single layer of potatoes on the roller bed. The halving machine also features self aligning rollers that position the products before they finally reach the cutting section. The potatoes are cut in half continuously, at the end of the roller bed. The halved potatoes are being collected beneath the machine by an additional belt.

Start/Stop Segmenting Machine – D

The Start/Stop Segmenting Machine – D is ideal for cutting (root)vegetables like potatoes into two, four or six pieces. This process can be done in two or more lanes by a start/stop system.

The PLC (Programmable Logic Controller) can be adjusted to match the speed of other machines and belts that are connected. This comes in handy when the halving machine is being put into a processing line, like our potato line.

In order to ensure a precise cut, a positioning sensor and control sensor are located behind the segmenting unit to measure distance between roller position and knife position in order to prevent any chance of the knives cutting into the rollers.

For cleaning purposes, the safety covers of the machine can be easily lifted by use of gas pressure springs. These can be opened one-handed, from both sides of the machine, so everything is still accessible despite conveyors or other elements at the end / below the roller bed.

Advantages:

Efficiency: Roller bed with custom-made diabolo rollers, based on the average length and diameter of your product. This creates the most optimal product positioning and therefore optimal cutting.

Durability: Due to the use of a servo motor the start-stop motion will not be abrupt, but with a soft acceleration and deceleration, which increases the durability of wear and tear parts.

Easy maintenance: Quick cleaning and easy parts replacement. Wear parts are easily accessible and are interchangeable for pre-assembled new items, minimizing downtime.

Safety and hygiene: Meets the strictest food safety standards.

More information about our industrial potato cutter

We hope we have a suitable industrial potato cutter for you. If you are looking for more information on our cutters or if you have any questions, please contact us. Just fill in the contact form and we will reach out to you as soon as possible. Also, note that we have several occasions that might be interesting for your business. You can also take a look at our total overview of machines here. Discover our complete collection here.

Contact form

Fill out our contact form and our team will reach out to you as soon as possible!

Contact information headquarters