Industrial French fries cutter

If you are looking for an effective way to cut potatoes into fries, then an Industrial French fries cutter of Marcelissen could be interesting to you. We have several machines that each have their own advantages. These cutters are suitable for food processing businesses, as well as the catering industry, such as restaurants. We will provide you with interesting details on a number of French fries cutters of Marcelissen.

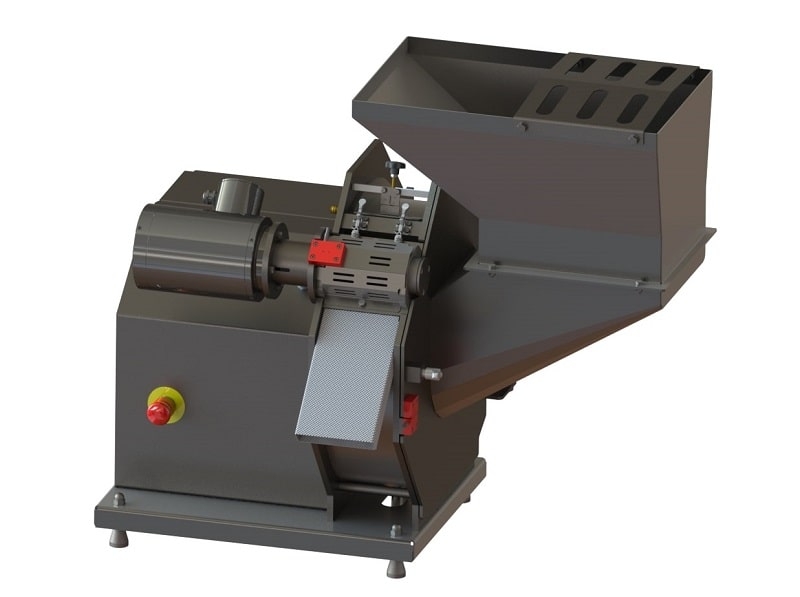

Slitmaster 105

One of the bestsellers of Marcelissen, the Slitmaster 105, is an ideal fries cutter for food-service businesses and smaller processing companies. Because of its relatively small size and clever design, it is being used in the kitchens of many restaurants.

The Slitmaster 105 is completely made of stainless steel and meets all CE safety regulations. By using the frequency converters, the speed of the drum as well as the knife can be adjusted to your specific needs.

The Slitmaster 105 is capable of processing potatoes with a diameter of up to 105 mm, making it perfect for producing large French fry potatoes. Not only does this machine consistently cut the longest possible fries from each potato — minimizing waste and short fries — but it also features a quick-release system for effortless switching between cutting sizes, saving valuable time and minimizing downtime.

This fries cutter is very easy to use and requires only a few steps:

Input potatoes/

Potatoes enter the rotor, which will be taken by the scoops.

Scoops take the potatoes and bring them to the ‘slice knife’, which creates potato slices.

These slices are finally cut into sticks by the ‘stick cutting knife’.

In order to ensure that the starch and grease that comes off the potatoes is washed off the Slitmaster 105, it’s advisable to use water during this process to keep everything clean.

The Slitmaster 105 offers the perfect blend of precision, efficiency, and user-friendliness for an optimal French fry cutting experience.

Hydro Cutter SH

At Marcelissen, we offer several hydro cutters, each with its own advantages. Below, we will discuss the different types in detail.

The Hydro Cutter is an industrial French fries cutter. It’s a lot bigger than the Slitmaster cutting machines and has therefore a much higher capacity (15.000 kg/hour compared to the 3.000 kg/hour of the Slitmaster). It’s therefore ideal for the bigger food processing companies. With this machine, the potatoes can be cut into chips, wedges and slices.

Because the Hydro cutter consists of several components, it’s possible to design the machine in such a way that it will fit in almost any production facility.

Hydro Cutter CSH

This cutter differs from the SH in terms of size. The Hydro Cutter CSH is a lot smaller and is considered to be the most compact hydro cutter in the world (it’s only 7,5 m2). Just like the SH, it comprises a centrifugal pump, water tank, venturi tube, cutting section, discharge conveyor and decelerator.

Next to the more compact design, it has other advantages to the SH, like:

A ‘quick-release system’ makes it easy to change the knife and venturi (takes around 20

seconds).

Requires less adjusting and fine tuning.

It’s a standalone machine on wheels.

Capacity up to 6.000 kg/hr

Interested in one of our industrial French fries cutters?

Are you interested in one of our industrial French fries cutters or would you like more information? Don’t hesitate to contact us! The easiest way is to fill in the contact form, we will in turn reach out to you. You can immediately leave a question if you’d like.

You can also browse through our complete assortment of machines. Additionally, we have some moderately priced occasions that might be interesting for you. Discover our complete collection here.

Contact form

Fill out our contact form and our team will reach out to you as soon as possible!

Contact information headquarters