Electric/industrial potato peeler

In order to properly process potatoes, an electric potato peeler is required. Therefore, Marcelissen offers a wide range of machines that deliver optimal peeling results. Due to their high capacities, these machines are best suited for industrial companies in the food industry.

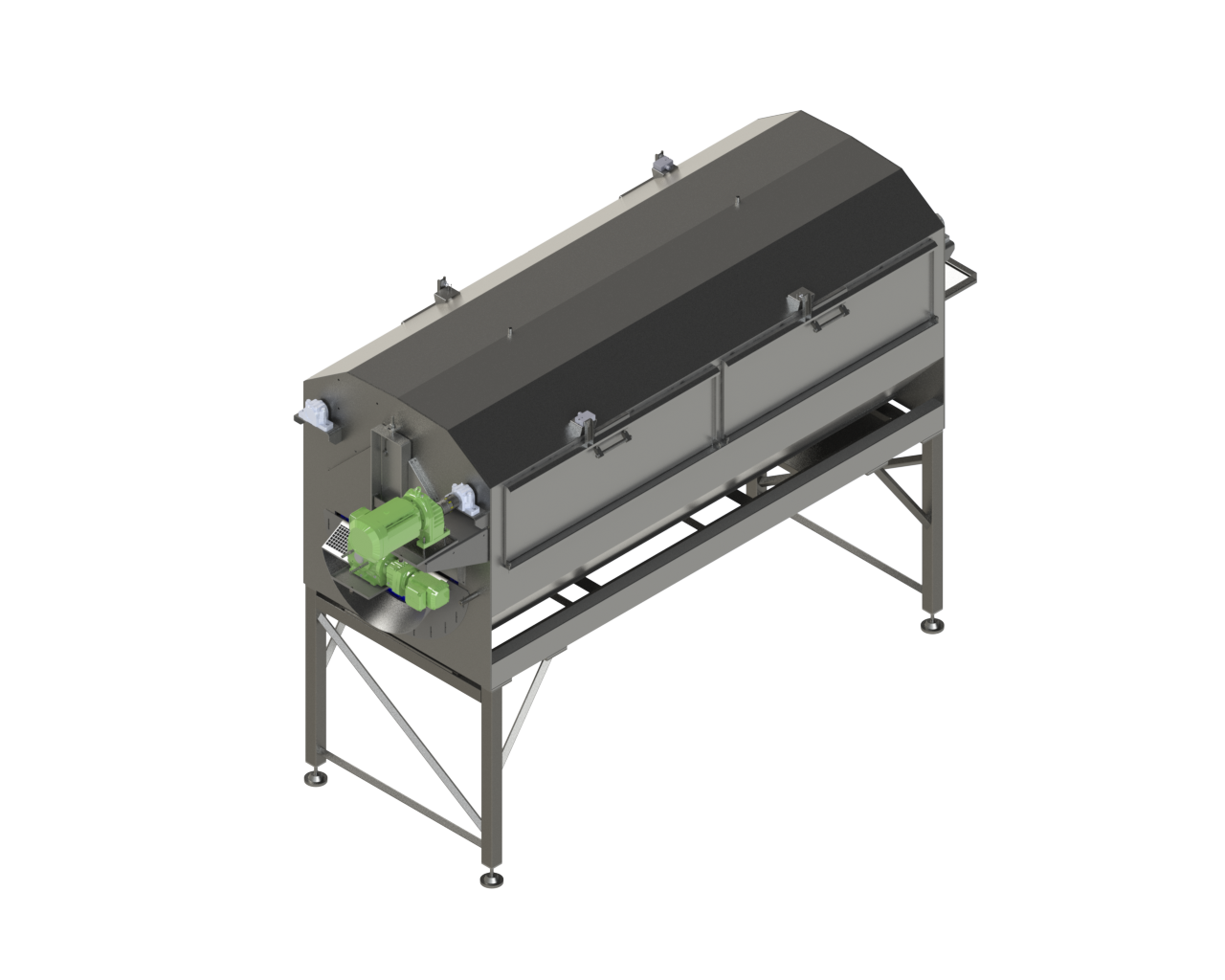

Drum Knife Peeler – SMT

The Drum Knife Peeler - SMT is an electric potato peeler consisting of three main components: the frame, a knife drum inside the machine and lastly the auger. By rotation of the knife drum and the auger, the potatoes are transported through the machine while at the same time getting peeled.

The knives are mounted on stainless steel beams. This not only prevents the knives from breaking, but also ensures that the knives and beams are easily replaceable. Normally, a breakdown of these types of machines results in long downtimes, as often the entire drum has to be removed. With our machines, however, knife beams can be replaced within minutes. In addition, the service life of our products is above average as we only use high quality stainless materials & plastics.

Further advantages of the SMT:

Efficiency: Every beam in the drum is completely made of stainless steel, and equipped with knives, even the cleaning/inspection beams. This ensures consistent peeling quality throughout the year.

Durability: For a longer lifetime of wear and tear parts, a rotex coupling is placed between motor and pulley. Also, due to the drum being completely made of stainless steel, the machine is considerably more durable compared to others on the market.

Easy maintenance: Quick, easy and affordable part replacement due to generic spare parts and drives, which can be locally sourced

Drum Roll Peeler – SKR

Unlike the SMT, the Drum Roller Peeler SKR consists of carborundum rollers assembled as one big drum. The machine is designed in such a way that the drum as well as the individual rollers rotate to peel the potatoes.

The main feature of the Drum Roller Peeler is that it processes inputs slowly. This ensures that all potatoes are peeled evenly. Through a frequency converter, the speed of the machine can be adjusted as desired, whereby the input of products should be evenly to obtain best possible results. Peeling residue and recycled water can be collected beneath the machine. In general, the SKR can also be used without water.

Further advantages of the SKR:

Durability: The drum rests on idler wheels to ensure stability and therefore better durability.

Easy maintenance: Quick parts replacement. Changing the rollers takes less than 10 minutes, minimizing downtime. Re-gritting the rollers is possible to do yourself, due to the use of carborundum linen instead of loose grit.

Safety and hygiene: This machine uses non-lube bearings, so there is no need to grease them. The round design ensures that peeling waste is disposed of easily.

U-bed Roller Peeler – SKRT

As the name indicates, the U-bed Roller Peeler - SKRT is used to peel off the skin of products. This specific type of Roller Peeler has carborundum rollers which together form a trough. One half of the rollers rotates anti-clockwise, the other half rotates clockwise.

A constant supply of products is of great importance for the peeling quality. That is why an auger has been mounted inside the trough that determines the transport time of the potatoes through the machine. By means of a frequency converter, the speed of both the rollers and the screw can be determined. Furthermore, the grid size on the rollers is based upon the product, product quality and the desired end result. Lastly, due to the fact that the rollers are positioned in a U-bed and not a drum, this leads to the advantage that a product that needs re-peeling can be dropped in the machine again from the top.

Just like the SKR model, peeling residue and wastewater can be collected beneath the machine.

Why an electric potato peeler from Marcelissen?

Our personal approach and excellent service in food processing projects, both large and small, make all the difference. By talking to companies about issues and the future challenges they face, we have, over the years, learned how to effectively improve and optimize processes.

Individual solutions.

Machines & product processing specifically designed to meet the needs of customers.

Highest quality.

High-performance, low-maintenance machines of the highest quality.

Innovative technologies.

Focus on continuous improvement and innovation.

Reduction of leftovers and waste.

Striving for sustainability for our customers and own processes.

Cooperation.

Long-term partnerships with our customers to help them grow.

Efficiency.

Machines and production processes are set up in the most efficient way possible.

Current customers of Marcelissen

Marcelissen has installed many machines and products at various customer facilities. They include large companies in the industry such as 'Cela Vita', 'Farm Frites' and 'Aviko', as well as smaller farmers and catering companies. For each of our customers we tailor a solution according to personal wishes and needs.

''After buying our first two potato lines from Marcelissen, 23 years later we are still a satisfied customer. Thanks to the maintenance contract we have with Marcelissen, the machines are still working perfectly. Our third line will certainly come from Marcelissen again!'' - Carl Verbist

Looking for more information?

For more information about our electric potato peelers, please fill out our contact form. We look forwad to supporting you. We also have multiple other machines that may be of interest to you. Click here for an overview of all our machines. We are also happy to schedule a personal appointment with you.

Contact form

Fill out our contact form and our team will reach out to you as soon as possible!

Contact information headquarters