Electric fries cutter food-service industry

An electric fries cutter for the catering industry is the ideal solution for cutting fries. Processing potatoes into fries at high speed is essential for the fresh food-service industry, snack bars and restaurants. Marcelissen offers various solutions in this area, which we would like to tell you more about.

Ideal solution for the fresh food-service industry

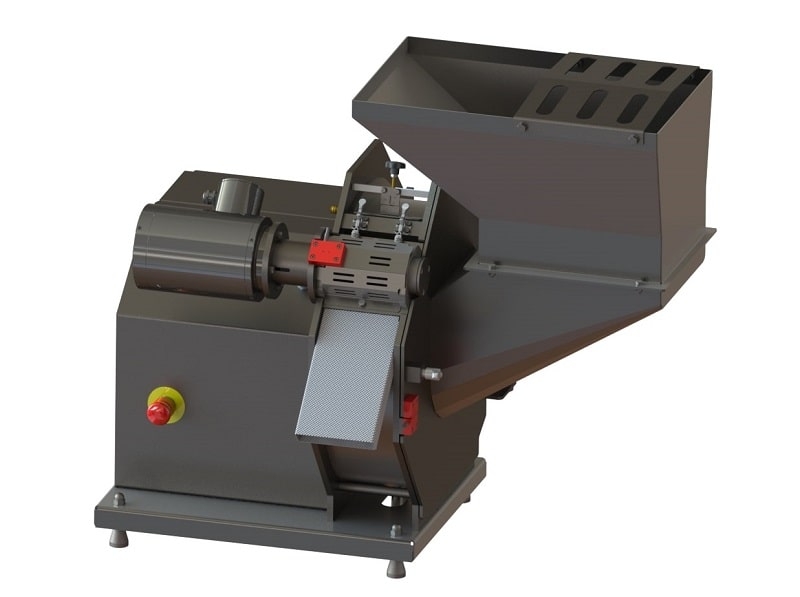

The Slitmaster 105 is the ideal solution for cutting potatoes into fries at high speed. Made entirely of stainless steel and in accordance with CE guidelines, the Slitmaster 105 has a capacity of up to 2.500 kg/hour. The thickness of the fries can also be adjusted to your wishes. Potatoes can also be cut into slices with this machine. Watch a demonstration of the Slitmaster below.

Operating of the Slitmaster

When the potatoes are fed into the machine, they end up in a rotor via an infeed gutter. This rotor then takes the potatoes with it and pushes them through the slicing knife. It is important that the bearing bushes are lubricated by fresh water to rinse away starch. A knife roller set or knife block set is not included as standard and must therefore be ordered separately. Besides the Slitmaster 105 we also have the Slitmaster 85. This model has a number of other properties. You can read more about them here. Technical specifications can be found below.

Attractively priced Fries Cutter

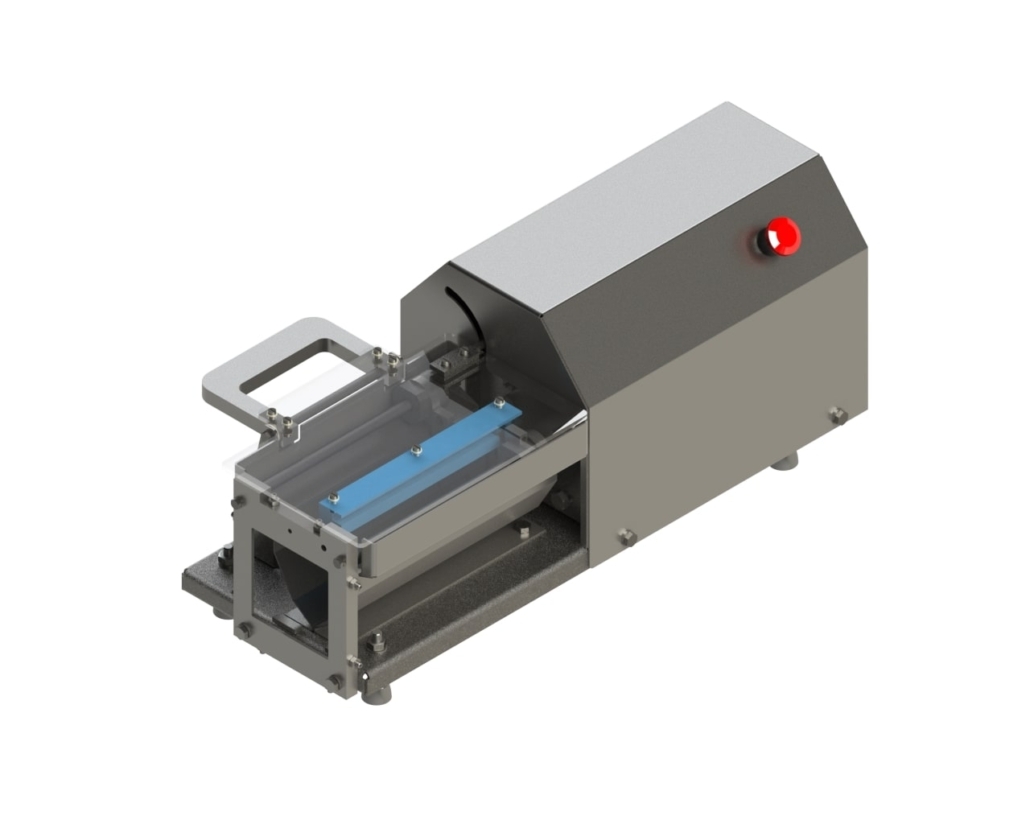

An electric chip slicer is ideal for the catering industry, although we understand that this is not equally affordable for everyone. That is why we also have a so-called pneumatic solution, which is a lot lower than the Slitmaster S in terms of price. This is the Slitmaster S, a cutting machine that is driven by a compressor. This chip cutter uses compressed air instead of electricity. However, the compressor is not included as standard.

Operation of the pneumatic Slitmaster

Potatoes can be administered through the top of the Slitmaster S. A pneumatic arm then pushes the potatoes through the knife section.

Besides the fact that this machine is very interesting from a price point of view, there are other advantages. Just like the Slitmaster 85 & 105, this model is completely made of stainless steel and meets the latest CE safety requirements. The capacity of this machine is higher than that of a hand cutter. Chips are cut straight and it is easy to use and maintain. Knives can be changed easily and the fries cutter is easy to clean.

* Depending on the product diameter, infeed speed and quality of the product.

Looking for advice on fries cutters for the fresh food-service industry?

There are many options for an electric fries cutter for the hospitality or food-service industry. Marcelissen’s Slitmaster machines are ideal for this, with the Slitmaster 85 & 105 being of the best quality. For those with budget restraints, the Slitmaster S (a pneumatic version) may be more suitable. For questions or more information about both machines you can always contact us. Please fill out the contact form and we will contact you as soon as possible.

Contact form

Fill out our contact form and our team will reach out to you as soon as possible!

Contact information headquarters