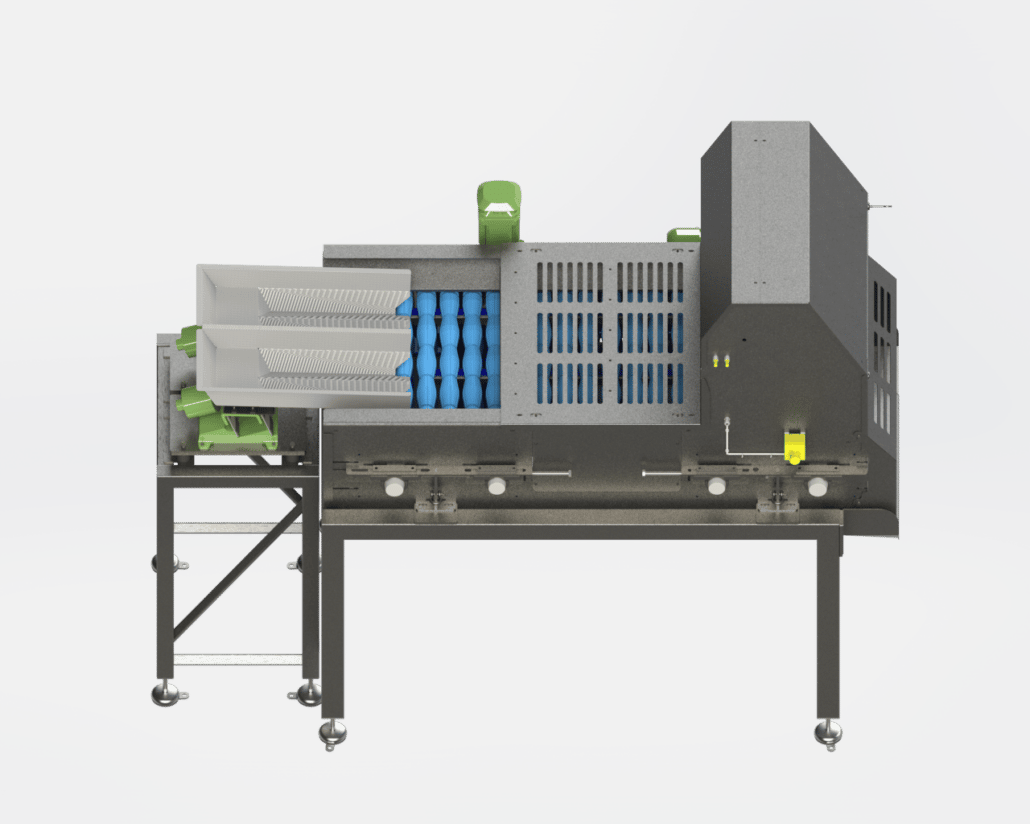

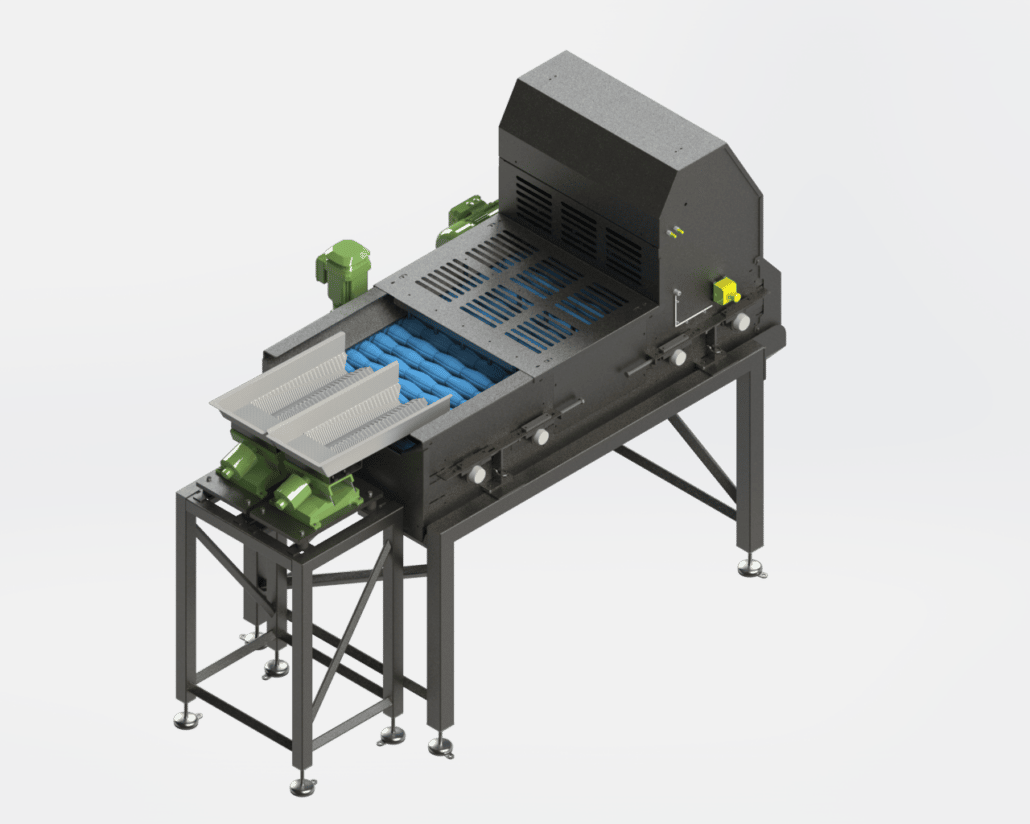

Upgraded halving/quartering machine!

The upgraded Marcelissen halving/quartering machine now has an even higher capacity, optimized cup positioning, and a longer life span.

The demand for cutting machines for halving and quartering potatoes remains undiminished within the market. This development requires further attention, which is why our R&D engineers have rolled out several updates to the Start/Stop dividing machine by combining the current machine data and the wishes/needs of our customers. In this article, we will outline the most important improvements of our revamped machine.

Capacity increase

Increasing the capacity is often accompanied by high costs for a larger machine. Especially in the current economic climate, such an investment is far from desirable. The cutting machine has therefore been developed in such a way that potatoes are now cut over not two, but three rows per lane. This provides a huge capacity increase while the size of the machine remains the same.

Of course, the current features, such as the modular number of lanes (available in 2, 4 & 6 lanes), remain. In addition, the knives can be individually adjusted for halving or quartering. For example, with a four-lane machine, it is possible to simultaneously halve on two lanes and quarter on the other two.

Improved positioning of the potatoes

The positioning of the potatoes plays an important role in the overall cutting result. The specially developed diabolo rollers are already tailored to the size and type of potatoes (un- & peeled).

On top of this, an improved drive control has been added, making acceleration and deceleration even better controlled. This ensures that, without additional fingers or other mechanical additions, the potatoes lie better in the cups during transport to the cutting system, which in turn improves the cutting result. Also, the guiding system of the knives during the cutting has been adjusted for a smoother cut.

Longer service life

After some time, the chain starts to develop some stretching, which can prevent the knives and rollers from aligning perfectly with each other. By adding a sensor to monitor the chain stretch, damages to the rollers during cutting are a thing of the past by sending a warning in time. This consequently reduces maintenance costs.

In addition to the rollers having a longer lifespan, the chain and bearings are also spared by the improved controls. The cutting motion puts less resistance on the parts and results in an overall longer machine life. In short, a completely improved machine in (almost) the same package!

Would you like to know more about the advantages of a Marcelissen cutting machine? Feel free to contact us via sales@marcelissen.nl or call +31 (0)77 475 20 02