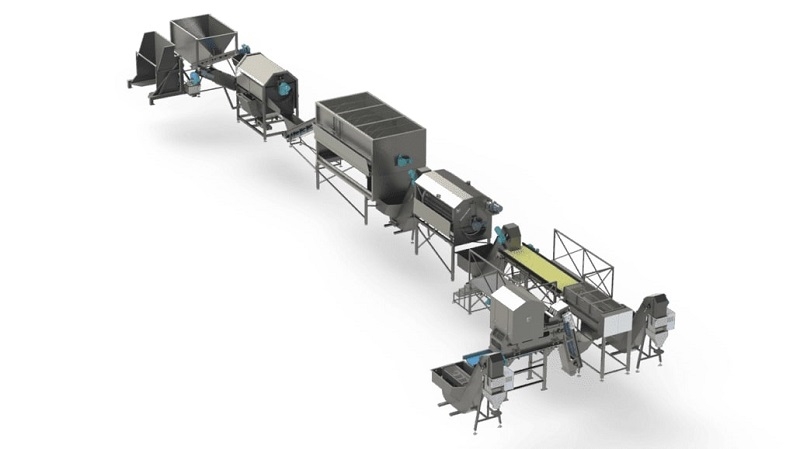

Potato Processing lines by Marcelissen

The optimal solution for the production process

Creating and installing a (tailor-made) potato processing line is a lengthy and intensive process whereby the aim should always be to find the optimal solution for the customer and his specific production process.

By visiting entrepreneurs and companies at their site, there is the opportunity to learn, talk and experience the questions and future challenges that the customer is dealing with. This thorough understanding of the production process and daily workflow are essential to every machine manufacturer in order to deliver a solution that will not only do the work it is designed to do, but also provides customers with an ease of mind and the chance to look to the future and react to new opportunities within their market.

Our starting point is always the desired end product and result of the customer. This means that instead of starting at the beginning of a processing line, the first question should be; ‘’what kind of end product(s) would you like to produce now and possibly in the future?’’ With the answer to the abovementioned question, our consultants actively start to form a solution whilst asking additional questions during the process. This slowly creates a clear picture for both consultant as well as customer as to what it is they exactly want or need in order to succesfully thrive in the future. After having brought to light all active and sub-conscious wishes of a customer, an offer can be drafted, based on their specific needs.

Upon order, engineering will start and take into consideration all imaginable aspects of a processing line. Not only lining-up machines, but more so focus on the location of water/air connections, the optimal distance between waste pumps to limit power usage or facilitating easy cleaning possibilities in hard to reach, customer specific, areas. This all ensures that the eventual line will best serve and adapt to the circumstances at the facility it will be installed.

In order to guarantee each project being handled according to the highest standards, the workflow of projects has been standardised as much as possible at Marcelissen according to the following steps:

Identification of customer’s wishes & needs (sketching)

Optimal solution determination in cooperation with Engineering and R&D

Production

Testing phase

Installation at the customer’s site

Commissioning of the production line

Evaluation & feedback

Service & maintenance

Knowledge of machines and the final product

Due to the fact that we’ve been active in the food processing business for over 70 years, we possess an extensive and intrinsic level of knowledge and experience which helps us to obtain a deeper understanding of customers’ needs and desires when it comes to turnkey processing lines. In order to deliver perfectly tailored processing lines, one should not only have a proper understanding of the mechanical or technical functioning of different machines and their influence on the customer’s product and end result, but also possess knowledge concerning the customer’s actual products that are being processed.

Take potatoes for example, after a hot summer potatoes are smaller than average and are therefore not ideal for making French Fries, meaning that alternative products could be an outcome in order to sell the smaller products and still achieve the highest possible yield.

On the other hand, when there is a very wet winter, the potatoes will often rot in the ground or show more defects than when being harvested after a relatively dry winter. This will result in more waste or oddly shaped products after being chipped. When you know wet winters can be common in certain areas, it gives the possibility to actively advice customers upfront concerning waste minimization and treatment in order to ensure the highest possible turnover, even when dealing with large amounts of waste in specific periods.

As you can see, it is important to have this deeper understanding of potatoes and what their lifecycle looks like in order to know how to process and store these products as best as possible in order to obtain the highest quality end product.

Innovation in machine technology

Apart from knowledge about our customers’ products and production processes, machine technology plays a vital role in staying on-top in the processing business. Where many machines within our portfolio have been introduced years ago and further optimised throughout the years, the development of new machines and incorporating technology in these already existing machines has become more and more important.

The best example of a machine innovation and therewith the transition towards an Industry 4.0, are optical sorting systems. These have become a vital part of almost every modern-day processing line. By using Vision technology, every single, unique potato can be directed to a specific step in the processing line in order to maximize the yield out of each separate product. Furthermore, by using Vision technology, other processes can be optimised as well using the gathered data. For example, when data analysis shows that almost no repeel is necessary, it can be concluded that too much product is being peeled off in the first place. This can (automatically) be corrected and therewith reduce waste whilst increasing yield at the same time.

In addition to the mentioned increase in Vision technology, sensors and software measuring tools are being incorporated into ‘traditional’ machines in order to enable the manufacturer to notice performance changes and predict maintenance as well as breakdowns before they take place. This way, customer and manufacturer can, instead of react to breakdown, pro-actively avoid these production stops. These new techniques and ways of reducing downtime all contribute to further stabilising the production process for customers around the globe.

Lastly, a trend in expanding product shelf life in a natural manner have been gaining more attention in the market. With manners varying from optimally using the features of knife peeling or new forms of packaging towards highly innovative methods using natural chemistry, this will be a field of innovation that will further develop and increase in importance in the near future.

Market trends: an increasing demand in potato processing lines

The demand for complete potato processing lines has been increasing the last years, especially in Eastern European countries. Due to an increasing GDP as well as one-person households and full time jobs, resulting in a higher expenditure of inhabitants, you can see the markets slowly moving towards more convenience food products such as pre-cut, sliced and/or blanched potatoes destined for supermarket convenience shelves. This in combination with the availability of government subsidies, farmers and small to medium-sized processors see opportunities to invest in larger processing lines with higher capacities as well as more advanced processing techniques. This trend will probably be one that will even further expand in the upcoming years, leading to interesting business opportunities for food-processing manufacturers as well as food-processing business.

Furthermore, the role of automation becomes even more important in the current economic and societal climate, where the focus has shifted (in western European countries) and is shifting (in eastern European and Asian countries), to reducing maintenance costs and labour cost. With factory workers being harder and harder to find, customers are looking for automated processing solutions that will have an equal but preferably better quality than the human labour used to provide in the old days. When they have the chance to operate at the same but preferably higher level of quality and quantity with a reduction of employees, they will not only make a decision based on the sales price of the machine but take into consideration the TCO just as well.

Another trend we have been seeing over the past years is that customers are shifting more and more towards to the principle of total project management. Meaning that the want to have one supplier taking on the complete project and delivering a turnkey solution, whereas in the past multiple suppliers often worked and communicated with the customer separately on a project, eventually delivering one total solution.

Responsible, innovative and technical, high-quality solutions

It is safe to say that turnkey projects, delivered by one main supplier, making use of sub-suppliers or not, are far from obsolete. If anything, the market will demand more and more all-in-one, worry-free solutions in the upcoming years. With younger generations looking for responsible, innovative and technical, high-quality solutions to offer streamlined production processes and therewith ease of mind, the potato processing market has a blooming future for all who value environmental neutral yet efficient food-processing.

Are you interested in a potato processing line specifically designed to your needs? Then feel free to contact us for more information. We are happy to answer all your questions.