Marcelissen and Industry 4.0

Partly due the rise of the internet and the digitization of the world around us, we find ourselves in what is often referred to as the Fourth Industrial Revolution, also known as Industry 4.0 or Smart Industry. As an innovative company in the manufacturing sector, we lead the way in regards to automation. How do we look at the market in general and, in particular, Marcelissen’s food processing machines? This blog focuses on the integration of Marcelissen food processing machines with the benefits that Industry 4.0 brings us.

What is Industry 4.0?

But first, what exactly is Industry 4.0? Under the banner of Smart Industry, numerous new opportunities are emerging for businesses. This revolves around the optimization of production processes, the development of smart custom-made products, and the elevation of business models to a higher level.

A crucial shift in this evolution is the increasing integration of data within manufacturing companies, made possible by a powerful combination of digital and technological innovations. This data provides more knowledge and insights into production processes. The results? Companies become more resilient and better prepared for the future by applying this new knowledge and reacting faster to process deviations. Furthermore, both product quality and company productivity improve by being able to take preventive action.

The Optical Sorter as an example

By combining existing machinery with innovative applications of digital tools, numerous advantages can be achieved for the food processing industry, including improved efficiency, higher product quality, reduced errors, and cost savings.

With smart automation and data integration, processes are seamlessly being optimized, which allows for more and better products.

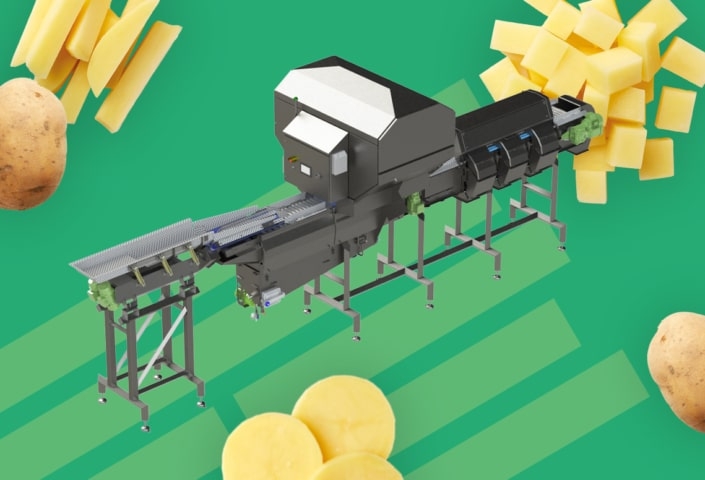

Take Marcelissen’s optical sorting machine, for example. By collecting data on the product and its quality, the process can be continuously improved. This data can be read remotely. Moreover, any malfunctions can be assessed from a distance by Marcelissen, reducing the need for on-site technicians and enhancing efficiency.

Other information can also be valuable, such as when a motor draws more current. One of the causes may be wear and tear. By conducting preventive and planned maintenance, downtime is minimized, and costs can be kept under control.

In the event of a malfunction in the control panels, we proactively contact the customer to address the issue collaboratively. The immediate transfer of information results in faster response times and reduced downtime for businesses!

Industry 4.0 is part of Marcelissen’s DNA

Marcelissen has always been at the forefront of innovative food processing machines. Not only in terms of technology but also in regards to safety and choice of materials, the machines have seen significant improvements in recent years.

The essence of Industry 4.0, the smart industry, is ingrained in our DNA. We continue to innovate, apply the latest developments, and maintain our leadership in the food processing market. This constant improvement enhances our customers’ production processes.

Our customers benefit not only from our knowledge and advancing insights, but also from the dedication to quality and service the Marcelissen team offers. The combination of our advanced technology and expertise makes our customers future-ready.